Crucible to prevent cracking of oled materials

A crucible and body technology is applied in the field of crucibles to prevent OLED materials from cracking, which can solve the problems of material waste and easy cracking of OLED materials, and achieve the effect of ensuring quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] In order to further illustrate the technical means adopted by the present invention and its effects, the following describes in detail in conjunction with preferred embodiments of the present invention and accompanying drawings.

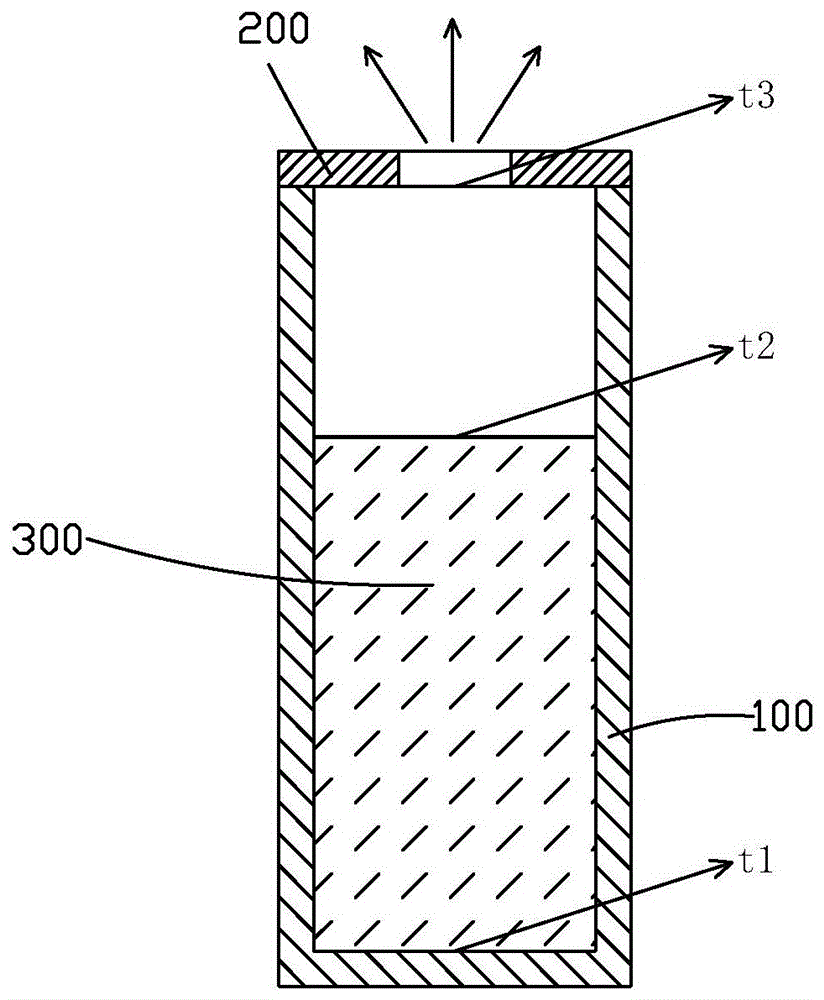

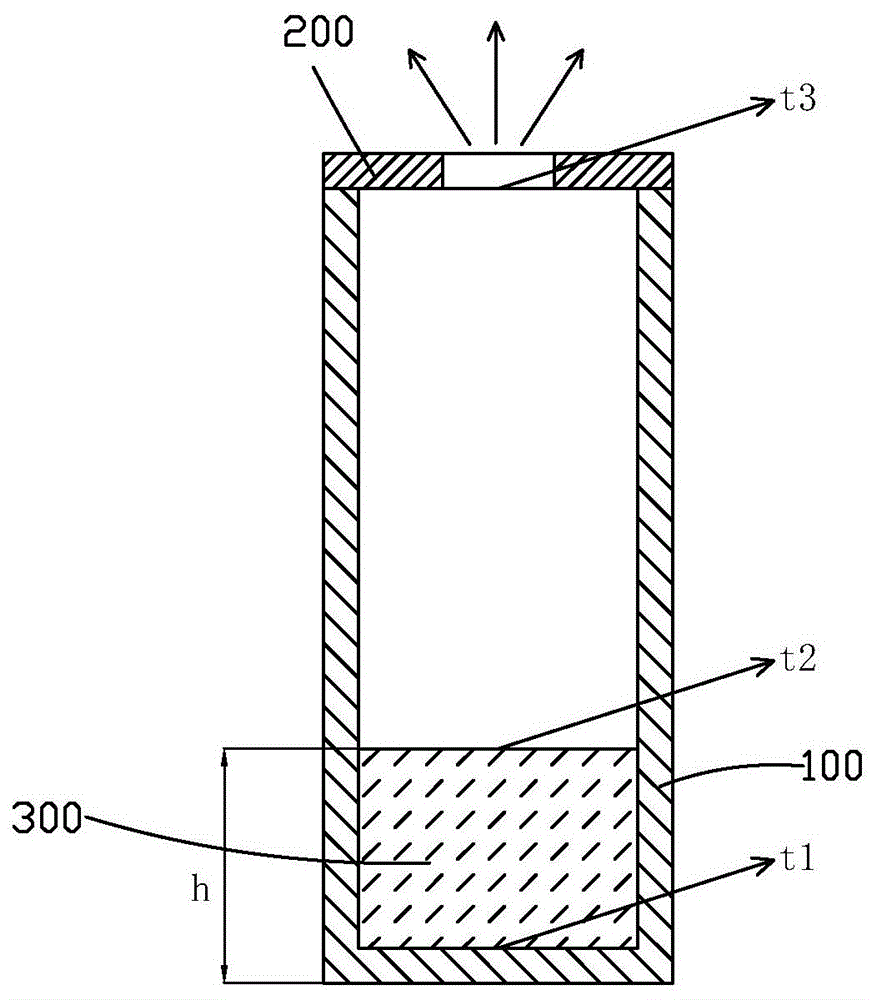

[0030] see Figure 4 , is a schematic cross-sectional structure diagram of the first embodiment of the crucible for preventing OLED material cracking according to the present invention. The crucible for preventing cracking of OLED materials includes a crucible body 1 for containing OLED materials 3 , and a cover 2 covering the opening end of the crucible body 1 .

[0031] The bottom of the crucible body 1 has a lifting structure 11, through which the height of the lowest liquid level of the OLED material 3 in the crucible is raised. The height H from the top surface of the lifting structure 11 to the bottom surface of the crucible body 1 is greater than or equal to the minimum liquid level height allowed for normal evaporation of the OLED mat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com