Ceramic tile batch processing accurate typesetting positioning construction process based on Internet of things

A construction technology and Internet of Things technology, applied in the direction of building structure, construction, etc., can solve problems such as the inability to guarantee the quality of brick laying, easy edge collapse, slow cutting and installation speed, etc., to improve the effect of floor decoration, avoid large errors, Solve the effect of slow installation speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

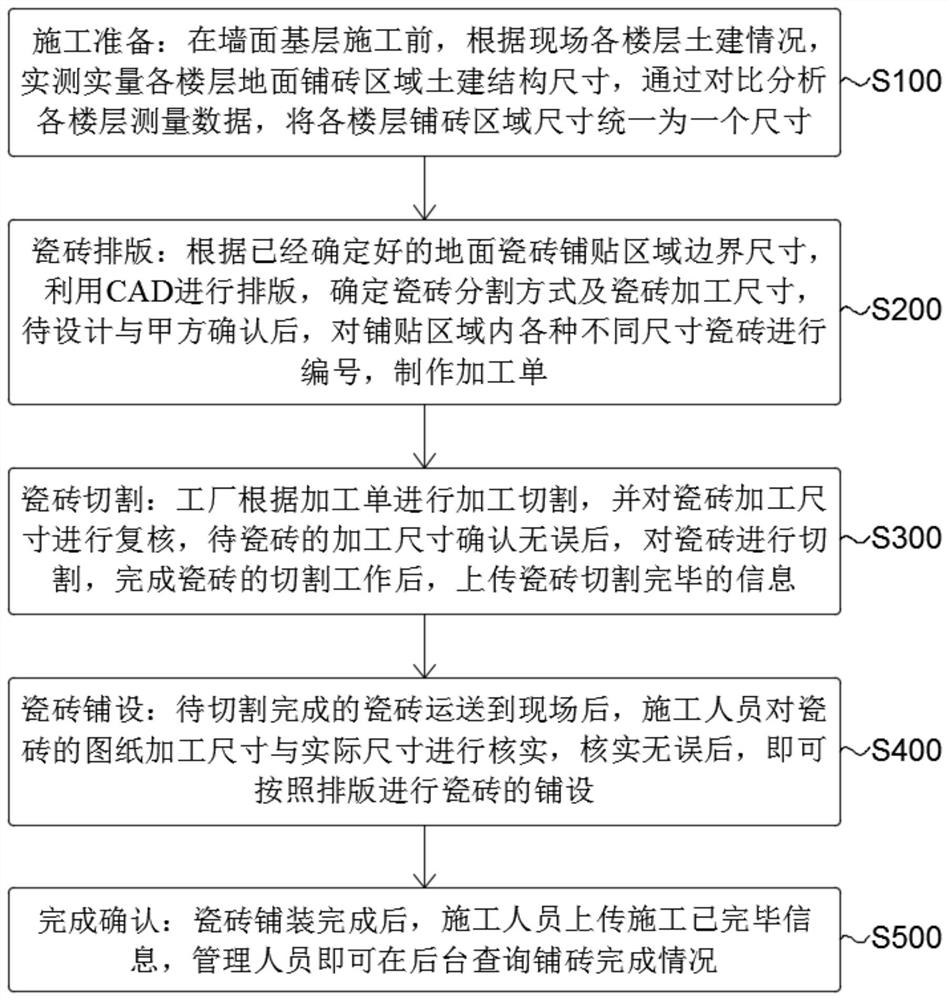

[0023] Please see attached figure 1 , an Internet of Things-based ceramic tile batch processing precise typesetting and positioning construction technology, including the following steps:

[0024] S100. Construction preparation: Before the construction of the base layer of the wall, according to the civil construction conditions of each floor on site, the size of the civil structure of the brick paving area on the ground of each floor is actually measured, and the size of the brick paving area of each floor is unified into one by comparing and analyzing the measurement data of each floor. size;

[0025] S200. Tile typesetting: according to the boundary size of the floor tile laying area that has been determined, use CAD for layout to determine the tile division method and tile processing size. After the design is confirmed with Party A, tile...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com