Welding recognition device for automobile parts

A technology for auto parts and identification devices, applied in auxiliary devices, welding equipment, auxiliary welding equipment, etc., can solve problems affecting production efficiency, product assembly errors, product scrapping, etc., and achieve the effect of solving product scrapping and material waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

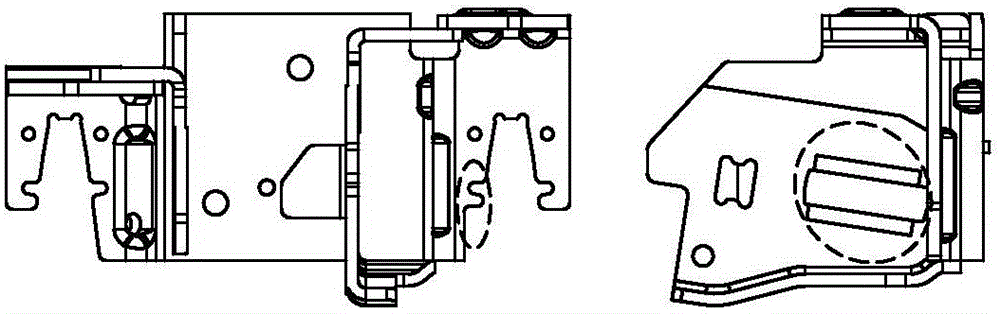

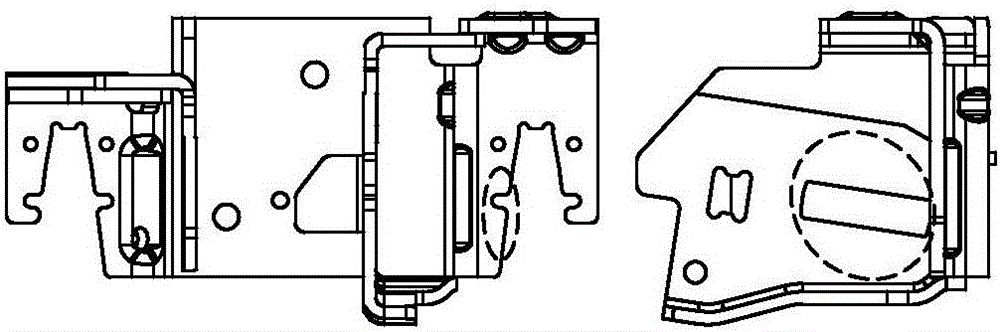

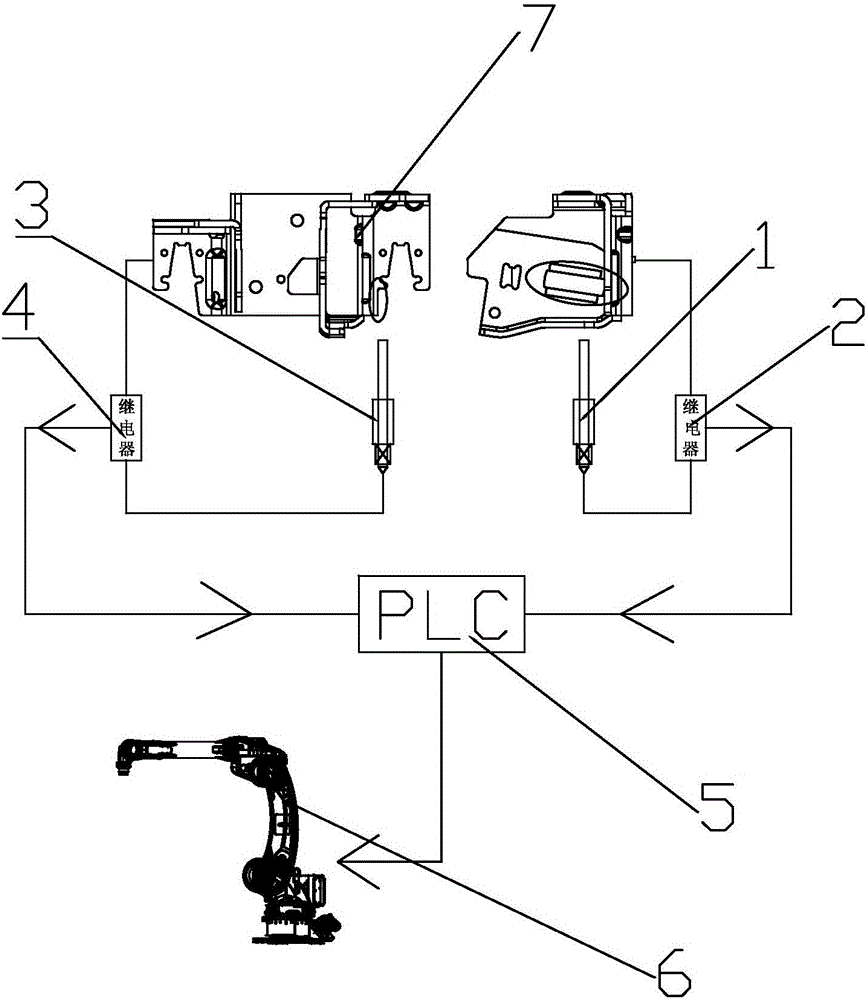

[0022] Such as image 3 As shown, a welding recognition device for auto parts includes jig 1 and jig 2 for placing the product 7 to be inspected, and a sensor for detecting the product to be inspected is arranged outside the jig 1 and jig 2 One 1 and sensor two 3, said sensor one 1 and sensor two 3 are respectively connected with relay one 2 and relay two 4, and said relay one 2 and relay two 4 are all connected with PLC control cabinet 5, and said PLC control cabinet 5 Connect with welding robot 6. in:

[0023] The PLC control cabinet 5 includes a cabinet body, a control panel is arranged on the outer shell of the cabinet body, and a control unit is arranged inside the cabinet body.

[0024] Such as Figure 7 As shown, the control unit includes a leakage circuit breaker, a fuse, a transformer, a switching power supply, a filter, a frequency converter, a terminal relay and a signal line terminal block, wherein the leakage circuit breaker is connected to the fuse, and the fu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com