Pipeline inner-wall spraying device

A spraying device and pipeline technology, which is applied to the device and coating of the surface coating liquid, which can solve the problems of high cost and low spraying speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

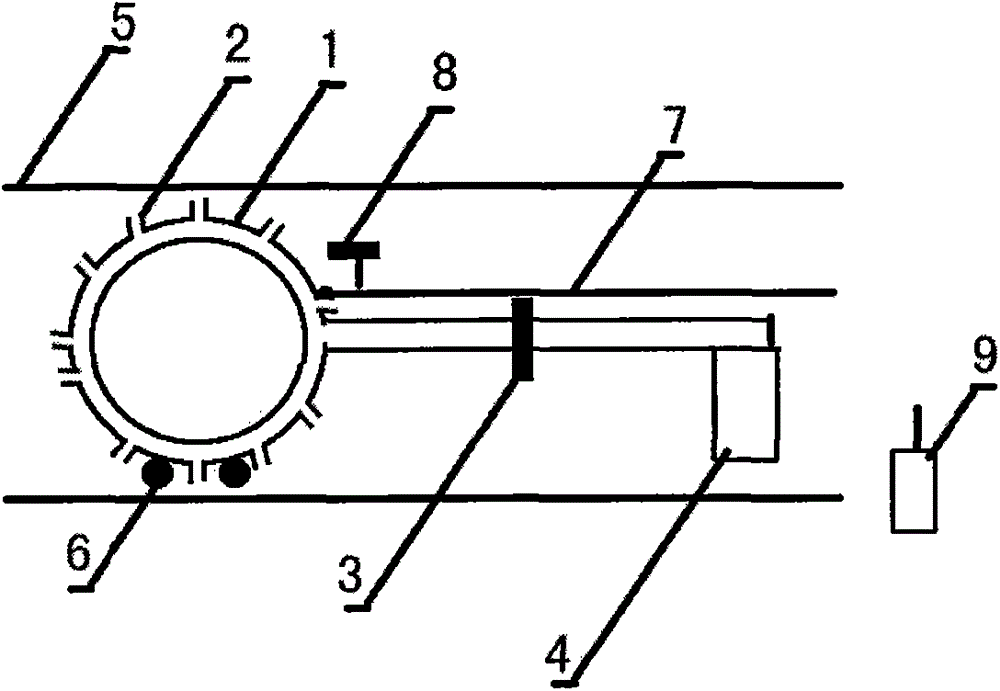

[0013] Embodiment: as shown in the accompanying drawing. Pipeline inner wall spraying device, including a frame [1], a circle of spraying pipes [2] are arranged on the edge of the frame, and the spraying pipes are connected with negative pressure generators [3] and paint tanks [4], and the negative pressure is activated when in use The generator [3] sprays the paint evenly on the inner wall of the pipeline [5].

[0014] The spraying device on the inner wall of the pipeline is equipped with a stepping device [6] at the bottom of the frame, which can move conveniently in the pipeline [5].

[0015] The pipeline inner wall spraying device is provided with a traction rope [7] at the end of the frame [1].

[0016] The spraying device on the inner wall of the pipeline is equipped with LED lighting components [8] to observe the condition of the pipeline wall.

[0017] The spraying device on the inner wall of the pipeline is equipped with a remote control device [9] to control variou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com