Vertical spray quenching apparatus and quenching technique

A technology of quenching equipment and vertical spraying, applied in the direction of quenching equipment, heat treatment equipment, manufacturing tools, etc., to achieve the effects of improving hardenability, shortening transfer time, and simple equipment structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

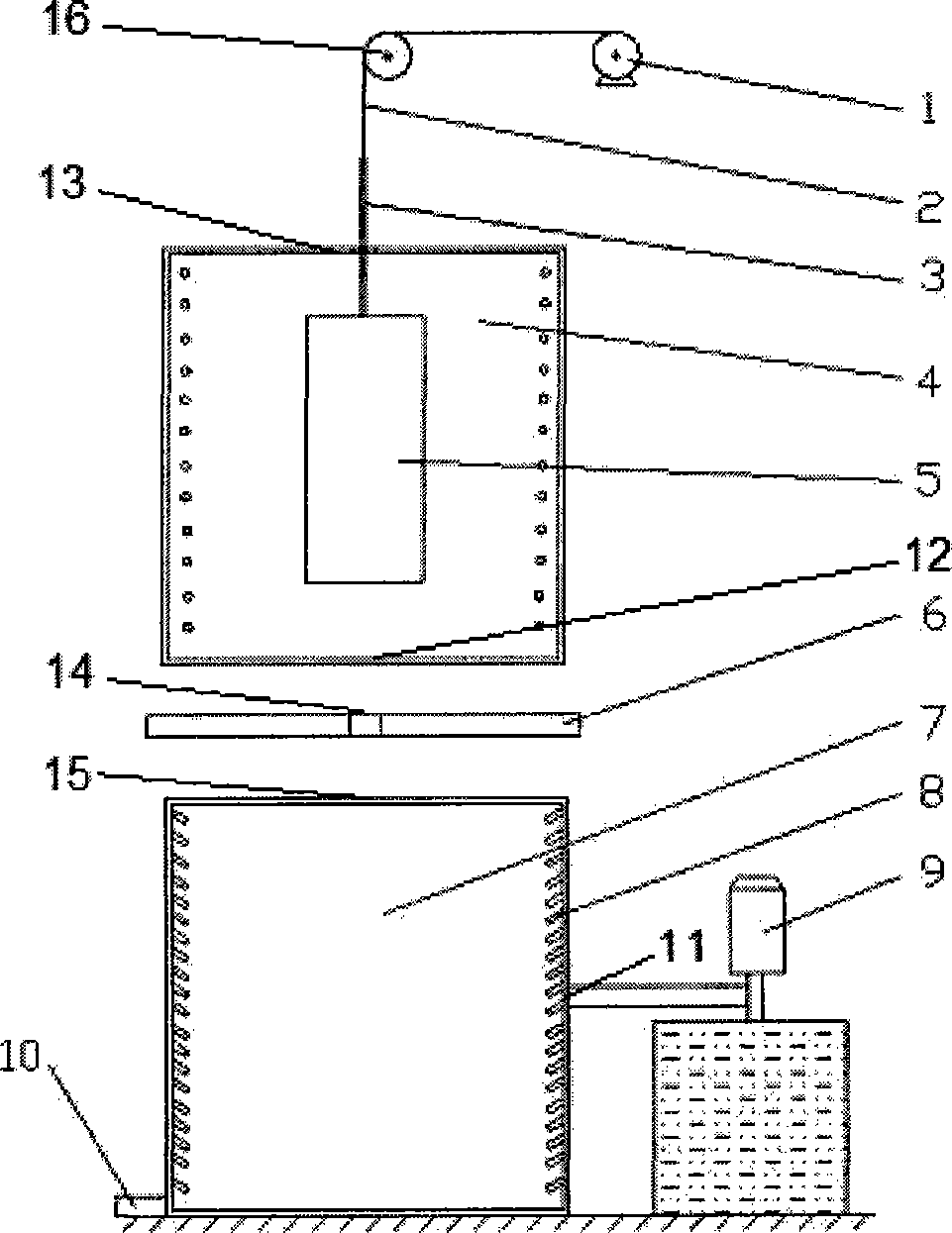

[0036] Embodiment 1 Vertical spray quenching equipment

[0037] like figure 1 As shown, the device includes the following components: a heating chamber 4, which has a feed inlet 13 at the top and a discharge outlet 12 at the bottom; a water vapor isolation plate 6 is arranged under the heating chamber 4, and the isolation plate 6 can be opened in half. There is a circular hole 14 in the middle that is slightly larger than the inlet and outlet rods; below the isolation plate 6 is a spray quenching chamber 7, with a feed inlet 15 at the top, a water outlet 10 at the bottom, and a plurality of water nozzles 8 in the inner ring. The external water source is pressurized by the booster pump 9 and sprayed into the spray quenching chamber 7 through the water inlet 11 through the water nozzle 8; The alloy workpiece (not shown in the figure) is put into the loading hopper 5, and the motor 1 drives the feeding rod 3 and the loading hopper 5 to move up and down through the pulley 16 hois...

Embodiment 2

[0038] Example 2 Spray quenching process of aluminum alloy extruded rods

[0039] First put the 2D70 aluminum alloy extruded bar with a diameter of 250mm into the loading hopper 5, start the feeding motor 1, pass the steel wire rope 2, use the feeding rod 3 to place the workpiece at a suitable position in the heating chamber 4, and turn on the power supply of the heating chamber 4 Solution heat treatment is carried out.

[0040] After the solid solution treatment is completed, the booster pump 9 is turned on and the valves of the water inlet 11 and the water outlet 10 are opened, the bottom door 12 of the heating chamber and the water vapor isolation plate 6 are opened, and the loading hopper 5 with the workpiece is lowered to the quenching chamber 7 In the appropriate position, the spray quenching treatment of the workpiece is completed by using the water nozzles 8 distributed in the ring.

[0041] After the quenching is completed, the booster pump 9 is turned off, the feedi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com