Quenching cooling conveying line for aluminum profiles

A technology for cooling and conveying aluminum profiles, applied in quenching devices, heat treatment equipment, manufacturing tools, etc., can solve the problems of simple and single quenching methods and poor effects, and achieve the effect of compact structure, convenient use, and normal quenching

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] Below in conjunction with accompanying drawing, the present invention will be further described by specific embodiment:

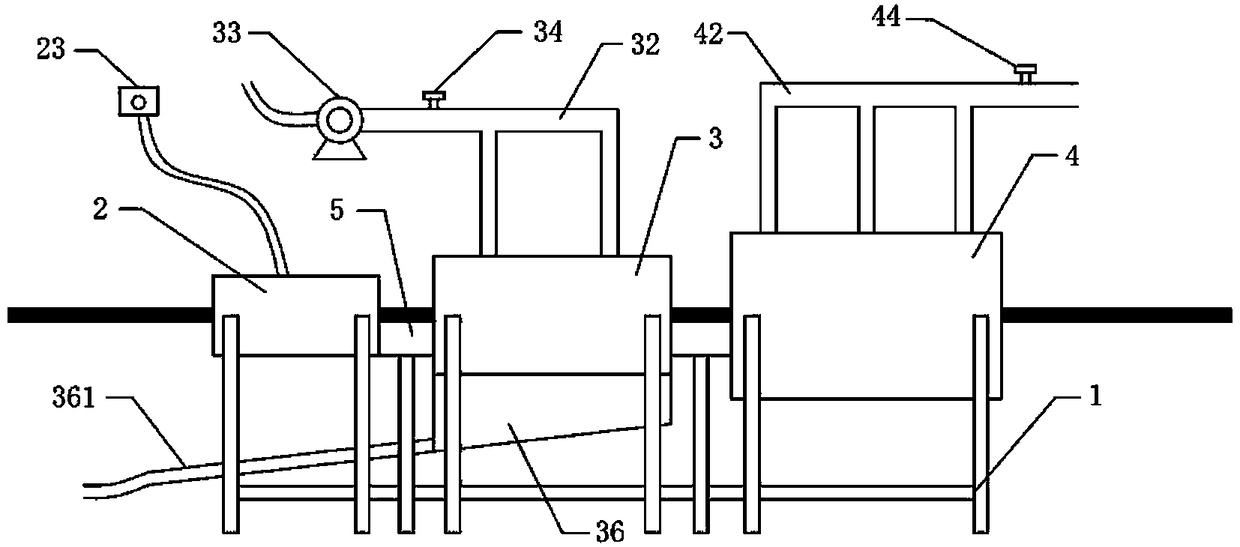

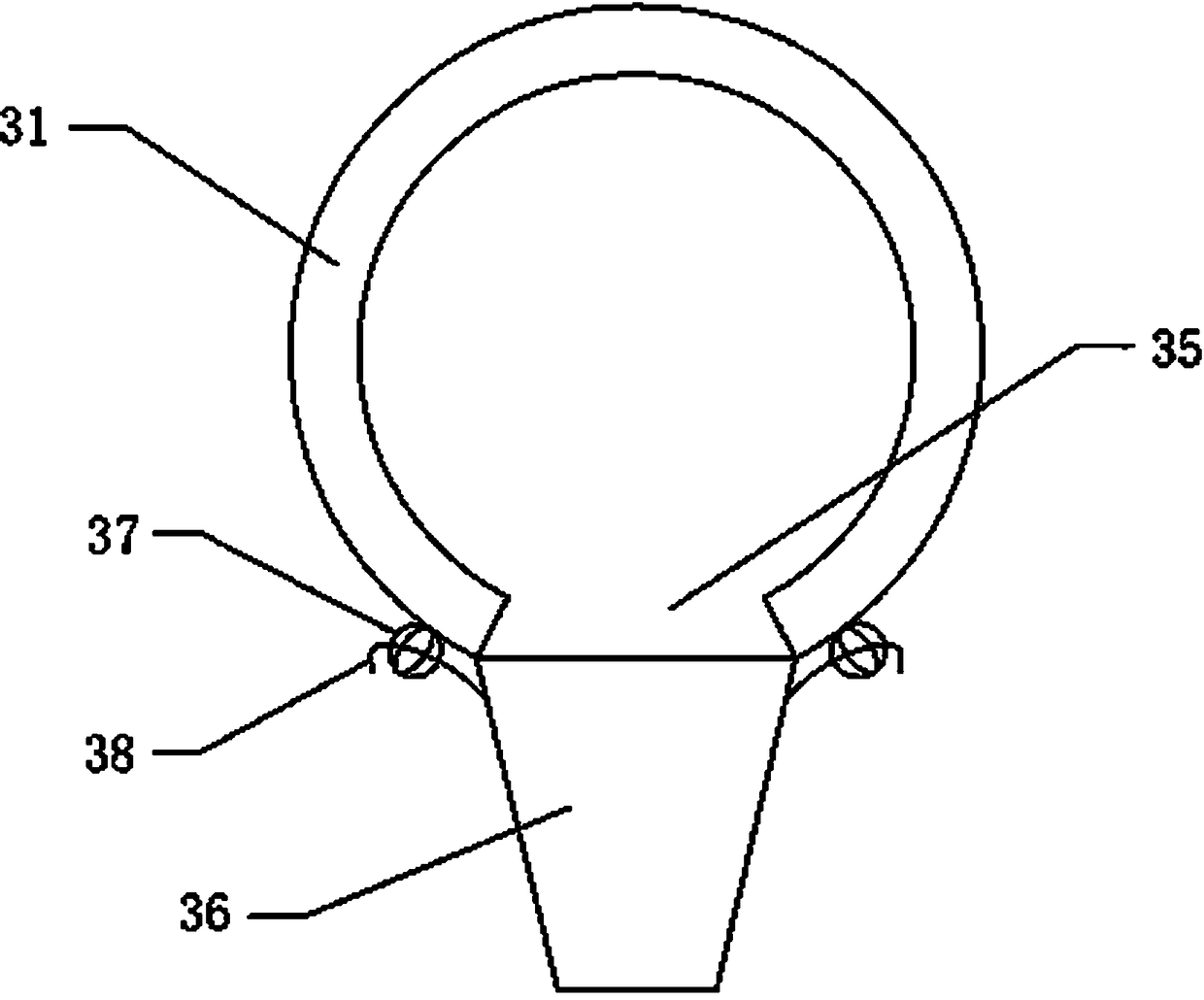

[0026] See figure 1 , an aluminum profile quenching and cooling conveying line, including a conveying frame 1 and a quenching and cooling system arranged on the conveying frame 1, and the conveying frame 1 is also fixedly connected with a supporting plate 5 for auxiliary transportation of aluminum profiles. The quenching cooling system includes a heat preservation mechanism set at the front end of the conveying support 1 to prevent excessive heat dissipation of the extruded aluminum profile, a liquid cooling mechanism set in the middle of the conveying support 1 and an air cooling mechanism set at the end of the conveying support 1 .

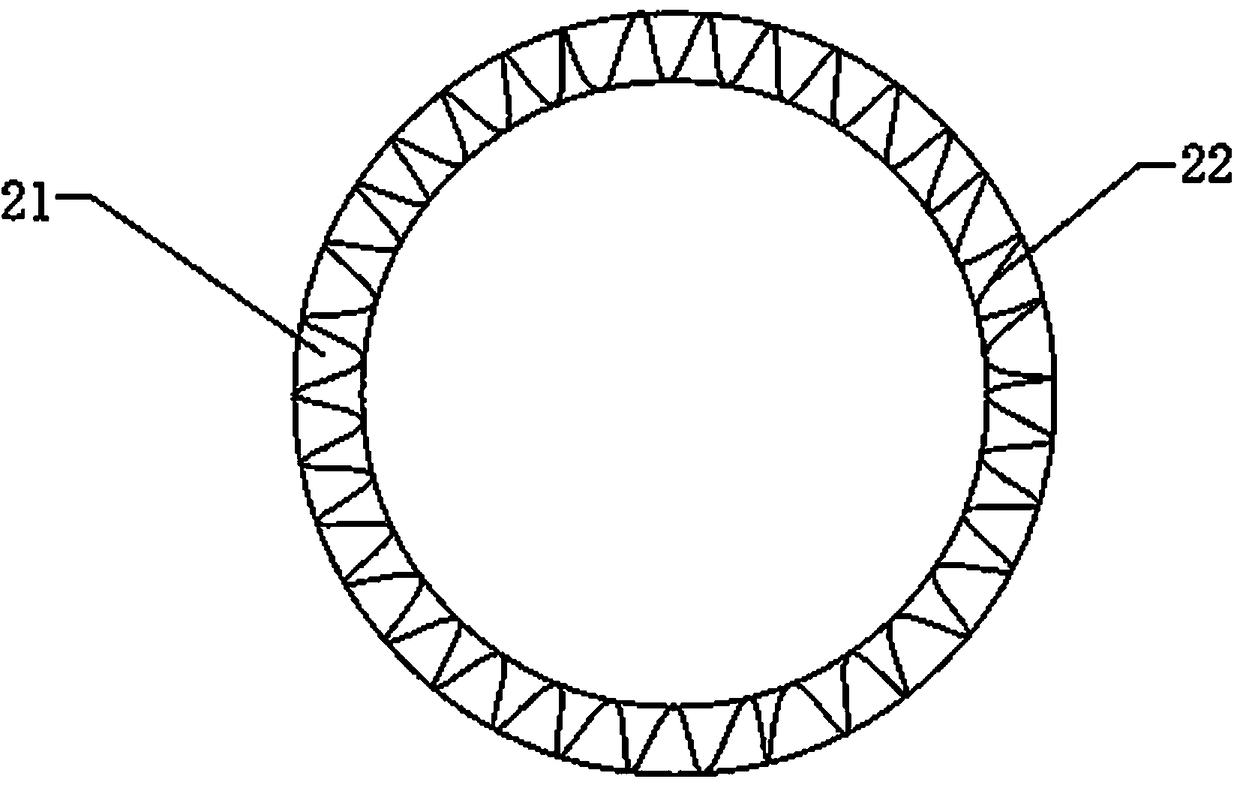

[0027] See figure 1 , figure 2 , the thermal insulation mechanism includes a heat conduction cylinder 2, a heat conduction interlayer 21 is arranged between the inner and outer walls of the heat conduction cylinder...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com