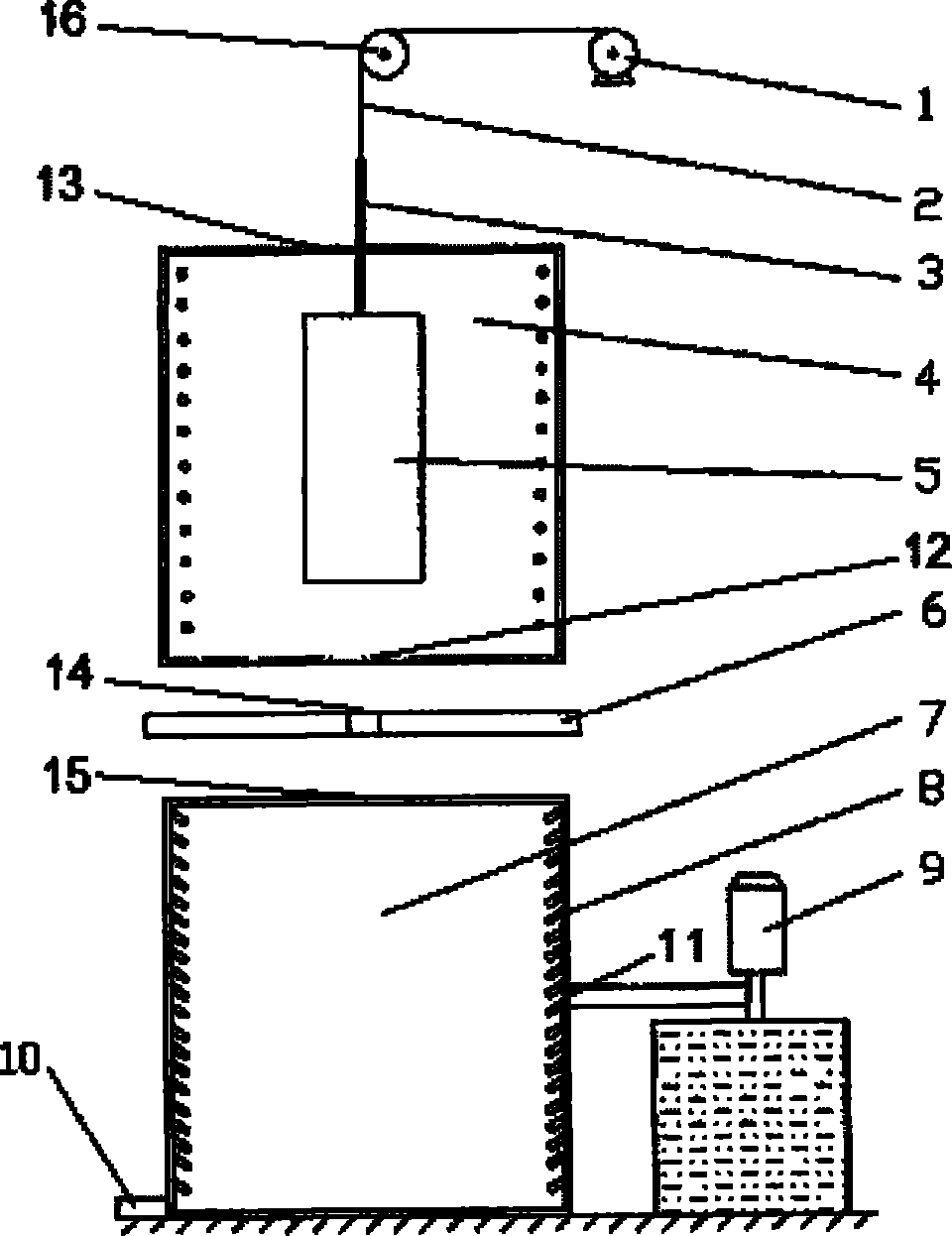

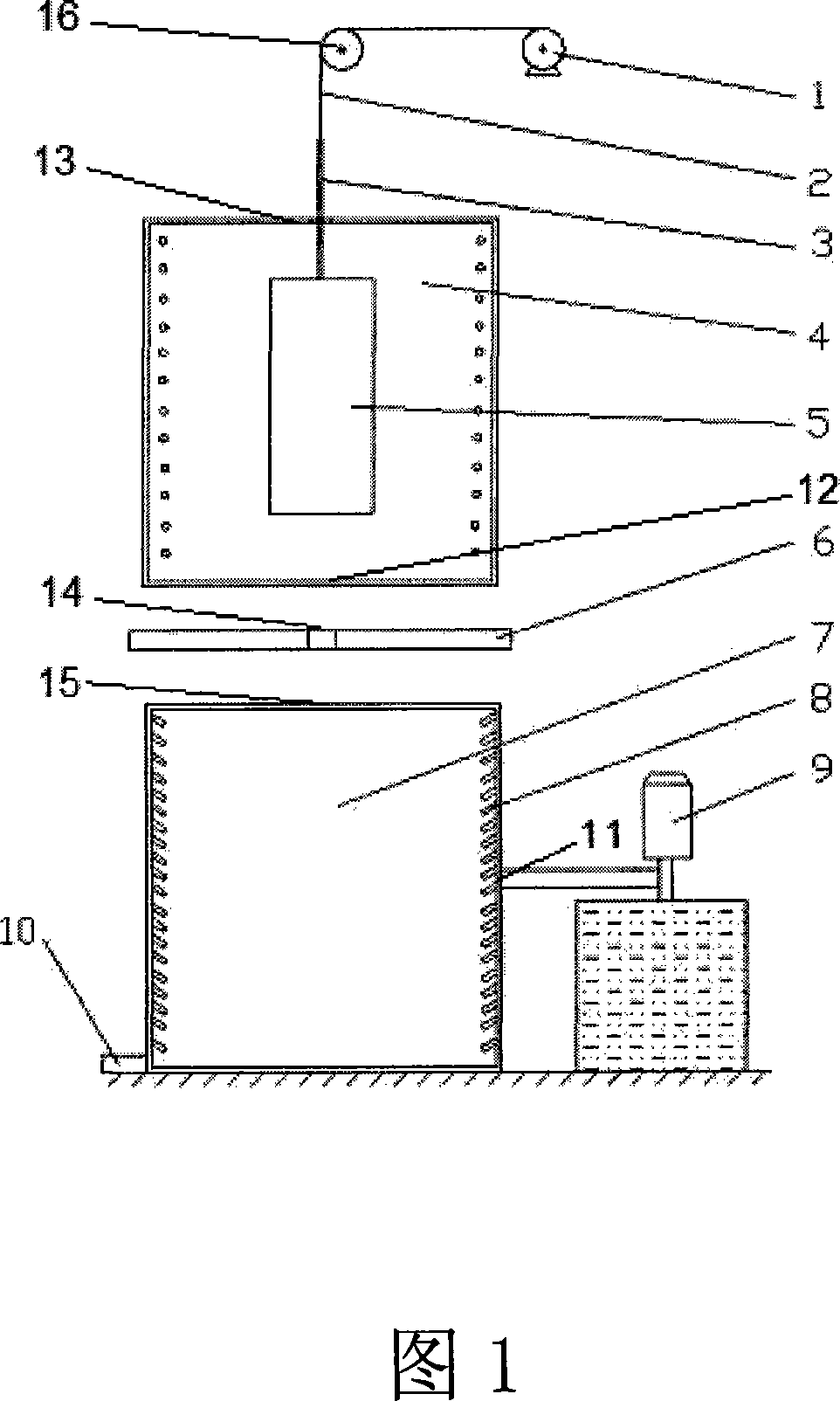

Vertical spray quenching apparatus and quenching technique

A technology of quenching equipment and vertical spraying, which is used in quenching equipment, heat treatment equipment, manufacturing tools, etc., to achieve the effects of improving hardenability, shortening transfer time, and simple equipment structure

Active Publication Date: 2010-11-10

GRIMAT ENG INST CO LTD

View PDF0 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Increasing the water flow velocity at which the water flow hits the surface of the alloy rod during quenching can break the vapor film generated during the quenching of the alloy, thereby effectively improving the hardenability of the alloy material, but there is no mandatory requirement for large-diameter alloy rods Report on Spray Quenching Equipment

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

Embodiment 2

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Login to View More

Abstract

The invention relates to quenching equipment and a quenching process for applying the quenching equipment, in particular to vertical type spray quenching equipment and a quenching process for quenching a large diameter alloy bar. The equipment comprises a heating chamber, a vapor division board, a spray quenching chamber, a feed-and-discharge control system, and a booster pump, wherein the heating chamber, the vapor division board and the spray quenching chamber are arranged vertically in sequence; and the feed-and-discharge control system transports workpieces to the heating chamber and the spray quenching chamber in sequence for heating and quenching treatment. The quenching process comprises the following steps: placing an alloy workpiece at a proper position in the heating chamber; starting a heating program for heating treatment; opening a water inlet and a water outlet of the quenching chamber after heating treatment; then opening a bottom door of the heating chamber, and opening the vapor division board simultaneously; carrying out the quenching treatment after the alloy workpiece enters the proper position in the quenching chamber through the feed opening of the quenching chamber, and closing the vapor division board at the same time; and closing a water inlet valve after finishing the quenching treatment and taking out the alloy workpiece from the top of the heating chamber.

Description

Vertical spray quenching equipment and quenching process Technical field The invention relates to a quenching device and a quenching process using the device, in particular to a vertical spray quenching device and a quenching process suitable for quenching large-diameter alloy bars. Background technique Large-size heat-treatable and strengthened alloy extruded bars have a wide range of applications in the aerospace field. As the diameter size of alloy bars increases, alloy materials encounter hardenability problems. The hardenability of the alloy has an important impact on the performance of the alloy, and also directly affects the safety issues during the aircraft service. How to improve the hardenability of large-diameter alloy bars so as to meet the demand for alloy materials in the aerospace field has become a hot spot of concern among alloy materials workers. Increasing the speed of the water flow impacting the surface of the alloy bar during quenching can break the vap...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): C21D9/38C21D1/667

Inventor 张永安熊柏青朱宝宏刘红伟王锋

Owner GRIMAT ENG INST CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com