Quenching device of stabilizer bar

A technology of quenching device and stabilizing rod, which is applied in the direction of quenching device, heat treatment equipment, furnace, etc., to achieve the effect of sufficient quenching, stable quenching process and concise structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The technical solutions of the present invention will be further specifically described below through examples.

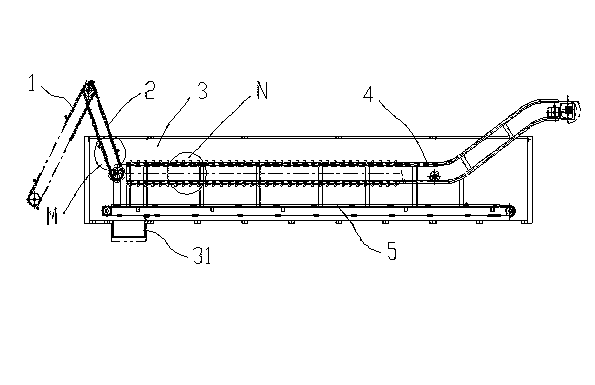

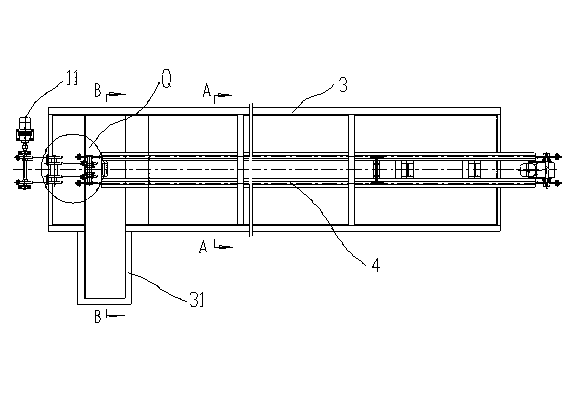

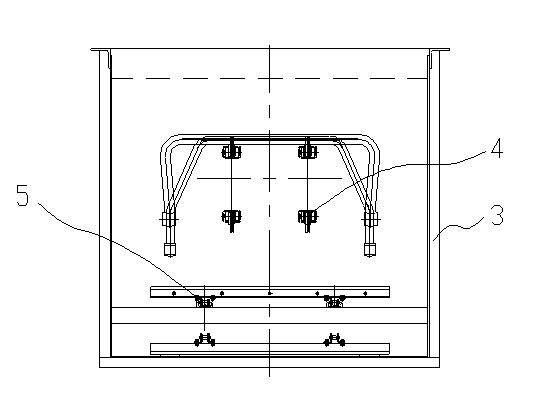

[0025] see figure 1 , figure 2 , image 3 , a stabilizing bar quenching device in the present embodiment, a cuboid oil tank 3 is set, and the oil tank 3 is provided with a liquid inlet and a liquid outlet, and the liquid inlet and the liquid outlet are respectively connected with the output pipe and the return pipe of the circulating liquid supply tank. Pipe is connected, and the oil liquid that quenching is filled in the oil groove 3, the height of oil liquid is higher than 25 centimeters of quenching walking chain 4 tops.

[0026] One end bottom of oil tank 3 is provided with sinking tank 31, and sinking tank 31 is arranged downwards by oil tank 3 bottom plate, and sinking tank 31 is arranged along the width direction of oil tank 3, and sinking tank 31 comprises horizontal section and inclined section, and horizontal section and inclined section form 12...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com