Quenching medium stirring cooling device

A technology of quenching medium and cooling device, applied in the field of quenching medium stirring and cooling device, to achieve the effect of ensuring the quality of quenching

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

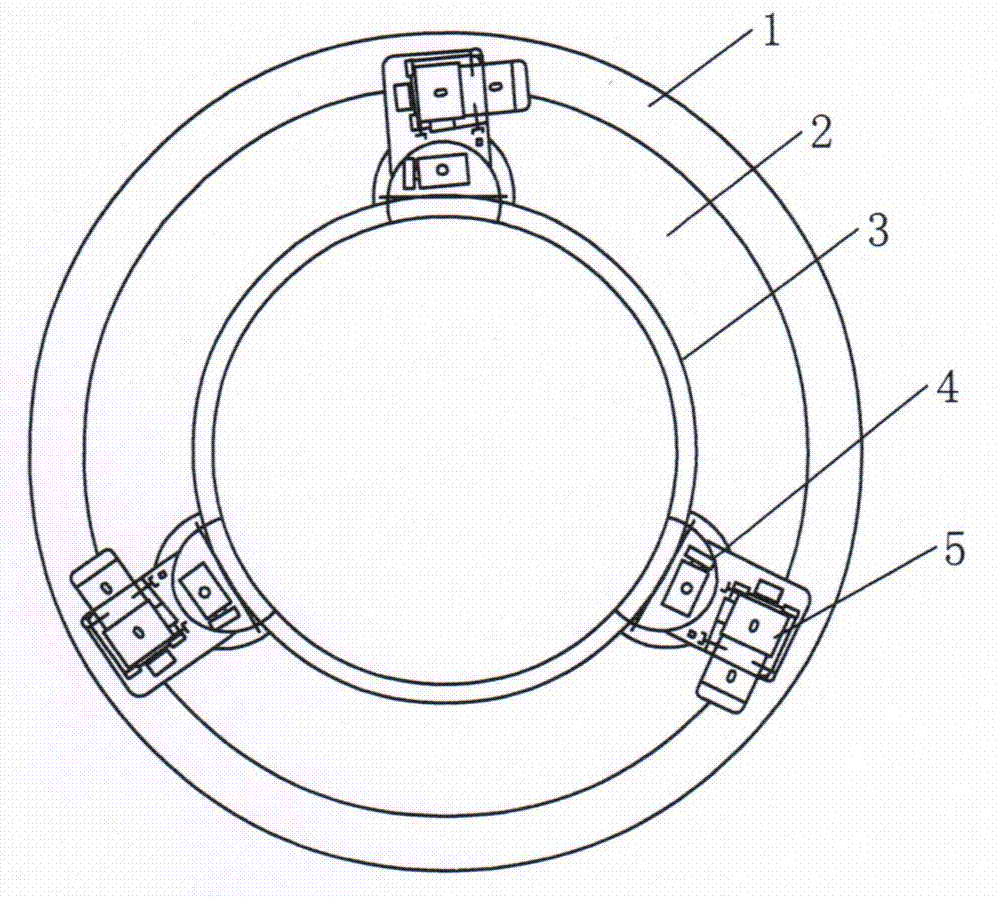

[0018] As shown in the figure, a propeller agitator 4 driven by a propeller speed regulating motor 5 is installed on the outer edge of the quenching liquid tank 3 at an angle of 120 degrees, and a cooling water circulation is provided between the periphery of the quenching liquid tank and the concrete waterproof wall 1 System 2.

[0019] Working process of the present invention: the quenching medium stirring and cooling device refers to the mode of combining propeller stirring mode, circulation pump cooling and manual rotation.

[0020] There is an included angle of 5° between the stirring direction of the propeller and the center of the quenching liquid tank. The propeller pushes the quenching medium to generate an eccentric oblique force when it is working, and the three propellers push the quenching medium to move in a circle. The other part of the force is under the action of the three propellers, and the liquid flow collides with each other to generate upward and downward...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com