Plate shearing machine tool rest with locking mechanism and tool thereof

The technology of a locking mechanism and a shearing machine is applied in the direction of knives, shearing devices, and shearing equipment used in shearing devices, which can solve problems such as transportation and installation difficulties, heavy overall structure weight, and increased manufacturing costs. Achieve the effect of improving workpiece quality, improving technical performance and production efficiency, and reducing plate distortion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

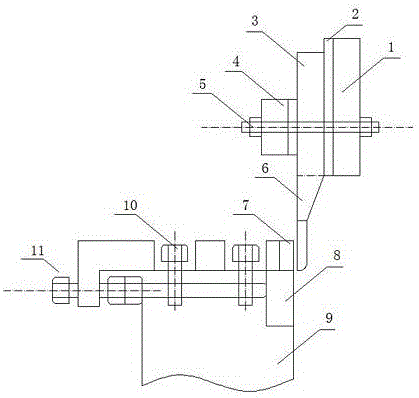

[0017] In the following, in conjunction with the accompanying drawings of the specification, the present invention will be further explained by taking the knife holder and its cutter of a certain shearing machine as an example.

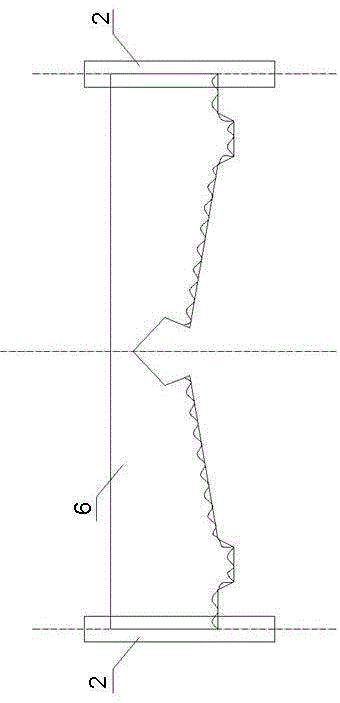

[0018] Such as Figure 1-2 As shown, the shearing machine tool holder with a locking mechanism and its cutters of the present invention includes an upper tool holder module and a lower tool holder module, both of which are fixed on the shearing machine platform The upper tool holder module includes an upper tool holder 1, an upper tool 3 and a tool guide rail 2. The tool guide rails 2 are fixed on both sides of the upper tool holder 1, and the upper tool 3 is embedded in the groove of the tool guide rail 2, and is in a fixed stroke. The lower tool holder module includes a lower tool holder 9 and a lower tool 8, and the lower tool 8 is fixed on one side of the lower tool holder 9.

[0019] The upper cutter 3 includes an upper blade 6, a tightening rib 4, a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com