Heat-treated steel material, method for producing same, and base steel material for same

A manufacturing method and steel technology, applied in heat treatment furnaces, heat treatment equipment, manufacturing tools, etc., can solve problems such as wrinkles and springback, and achieve the effect of reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

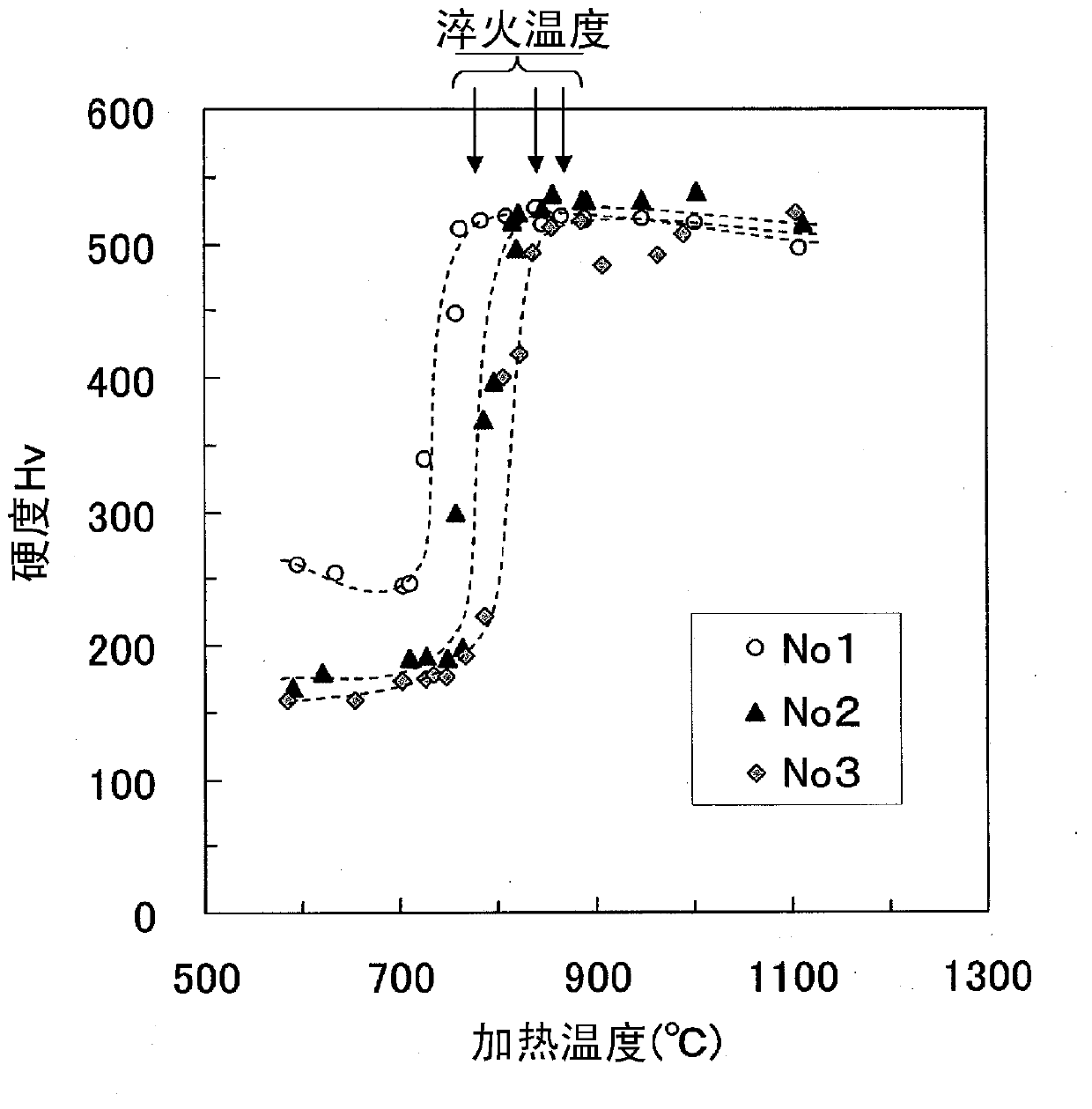

[0115] The continuous casting castings A~I with the chemical composition shown in Table 1 are put into the heating furnace for heating, taken out from the heating furnace, hot rolling is started at 1150°C, hot rolling is terminated at 870°C, and hot rolling is started at 20~1000°C / sec Cool at an average cooling rate, and coil at 450 to 600°C to form a hot-rolled steel sheet with a thickness of 3.6 mm. The hot-rolled steel sheet thus obtained was descaled by pickling. The steel sheet obtained in this way is called "hot-rolled material".

[0116] A part of the descaled hot-rolled steel sheet was cold-rolled at a cold-rolling rate of 50% to form a cold-rolled steel sheet. The steel sheets are called "high hardness cold-rolled sheets (full hard materials)".

[0117] A part of the obtained cold-rolled steel sheets were kept in a heating furnace at 650° C. for 20 hours, and then air-cooled to room temperature. This steel plate is called "heating furnace material".

[0118] In ad...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com