Multi-point-based large-curvature panel ultra-precision machining flexible clamping system

A technology of ultra-precision machining and flexible clamping, which is applied in the direction of metal processing equipment, metal processing machinery parts, clamping, etc., and can solve problems such as inaccurate positioning and difficult clamping

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The technical solution of the present invention will be further described below in conjunction with the accompanying drawings.

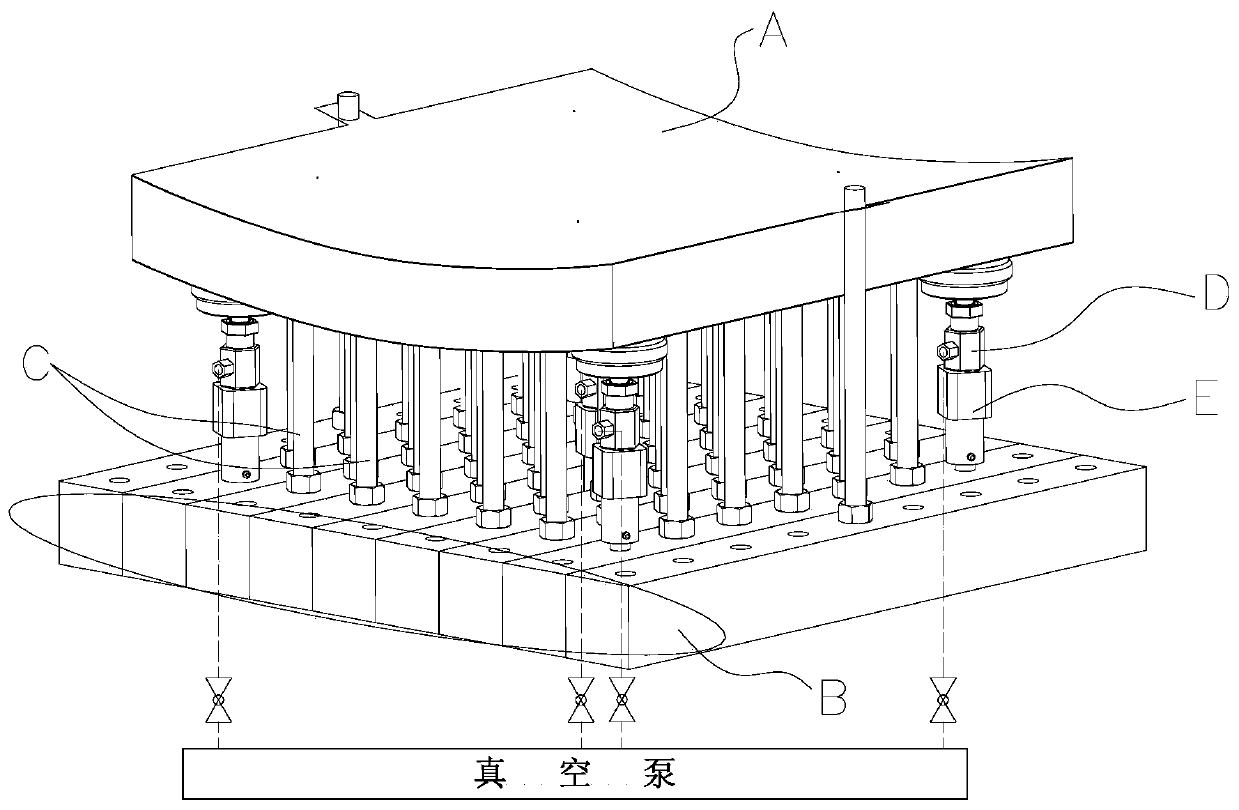

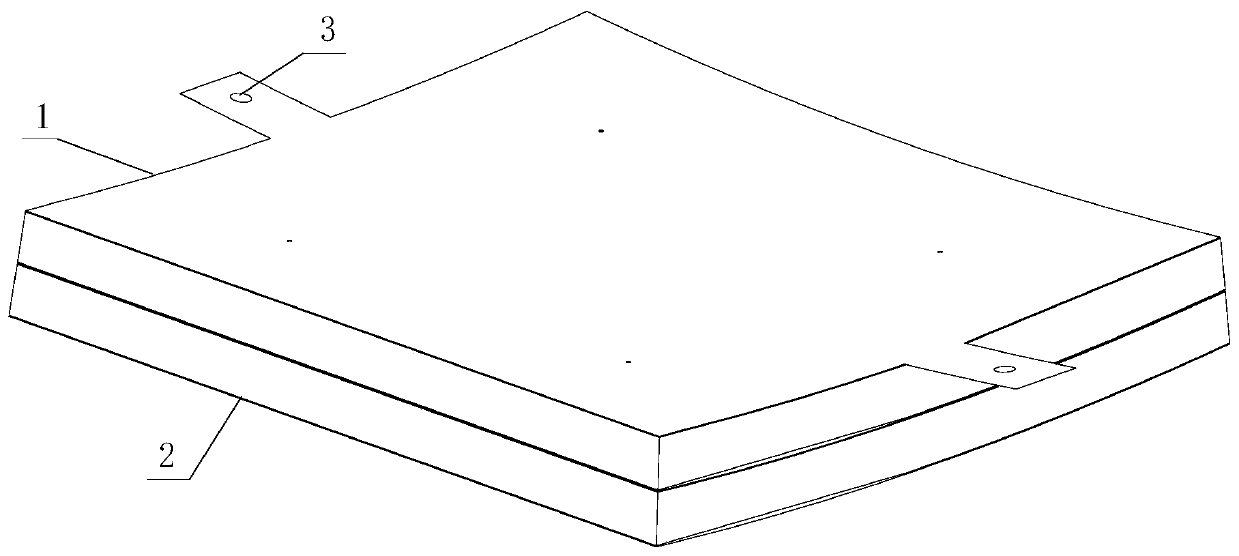

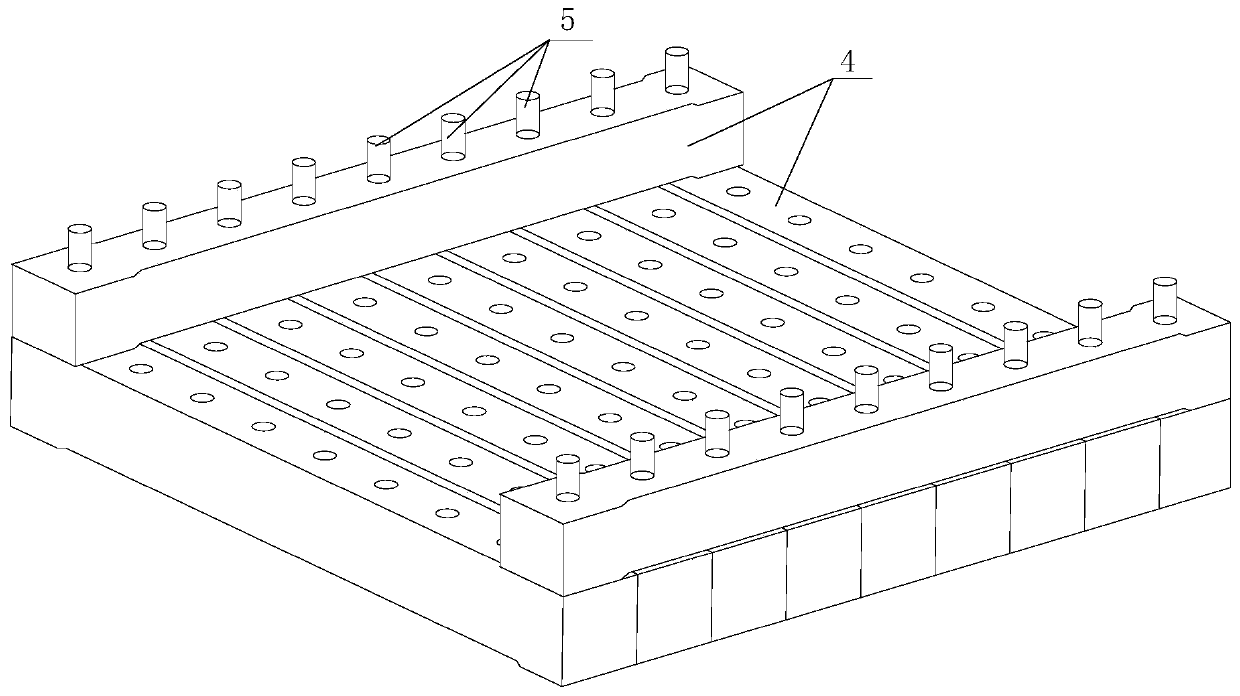

[0034] The flexible clamping system for ultra-precise machining and positioning of large-curvature sandwich structure high-precision panels involved in the present invention mainly includes large-curvature reflective panels A, base B, height-adjustable nail posts C, universal vacuum suction cups D, and transition connectors E, such as figure 1 Shown is a schematic diagram of the structure of the flexible clamping tool installed with the reflective panel of the sandwich structure. The specific structure of each part is as follows:

[0035] In order to improve the surface accuracy of high-precision reflective panels with large-curvature sandwich structures, it is necessary to perform further ultra-precision machining on the high-precision panels after vacuum negative pressure forming. The premise of ultra-precision machining is to fully position...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com