Substrate positioning method suitable for screen printing technology

A technology of screen printing and positioning method, applied in screen printing machine, printing, printing machine and other directions, can solve the problems of camera mechanical error, long printing cycle, etc., to avoid mechanical error, short printing cycle and high accuracy Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described below in conjunction with the accompanying drawings and examples.

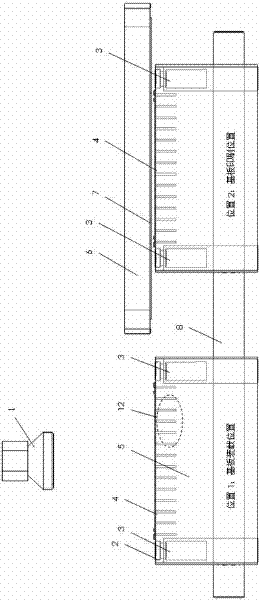

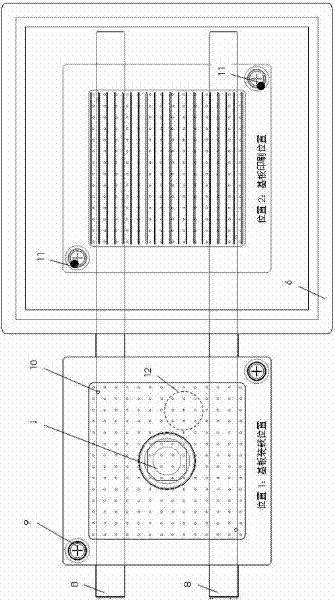

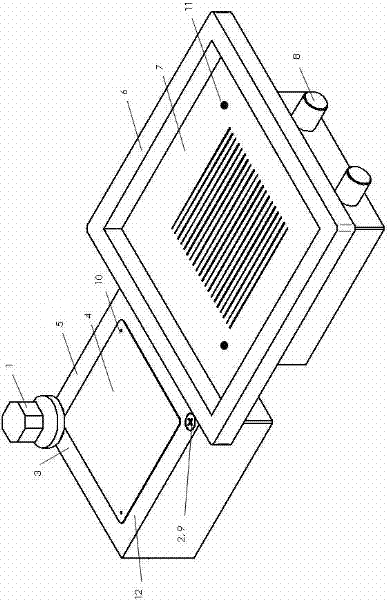

[0028] combine figure 1 , figure 2 , image 3 , Figure 4 As shown, a substrate positioning technology suitable for screen printing technology, including:

[0029] 1) The present invention has an upper visual optical device 1 , a lower visual optical device 3 and a movable printing table 5 . In this technology, PCB, wafer, silicon wafer or other forms of printed substrates are loaded on the substrate loading position, and the substrate 4 is fixed on the surface of the printing table 5 by means of vacuum adsorption and fixation 12 .

[0030] 2) After the substrate 4 is fixed, the upper vision optical device 1 is used to scan the substrate 4 and the printing table 5, and when the reference mark 10 of the substrate and the reference mark 9 on the surface of the printing table are observed at the same time, the reference mark of the substrate is recorded ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com