Uniaxial two-way micro mechanical measurement device and method for scanning micro environment

A uniaxial, bidirectional, scanning microscopy technique, used in measuring devices, using stable bending force to test material strength, and using stable tension/pressure to test material strength, etc. Implementation, expensive instruments, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

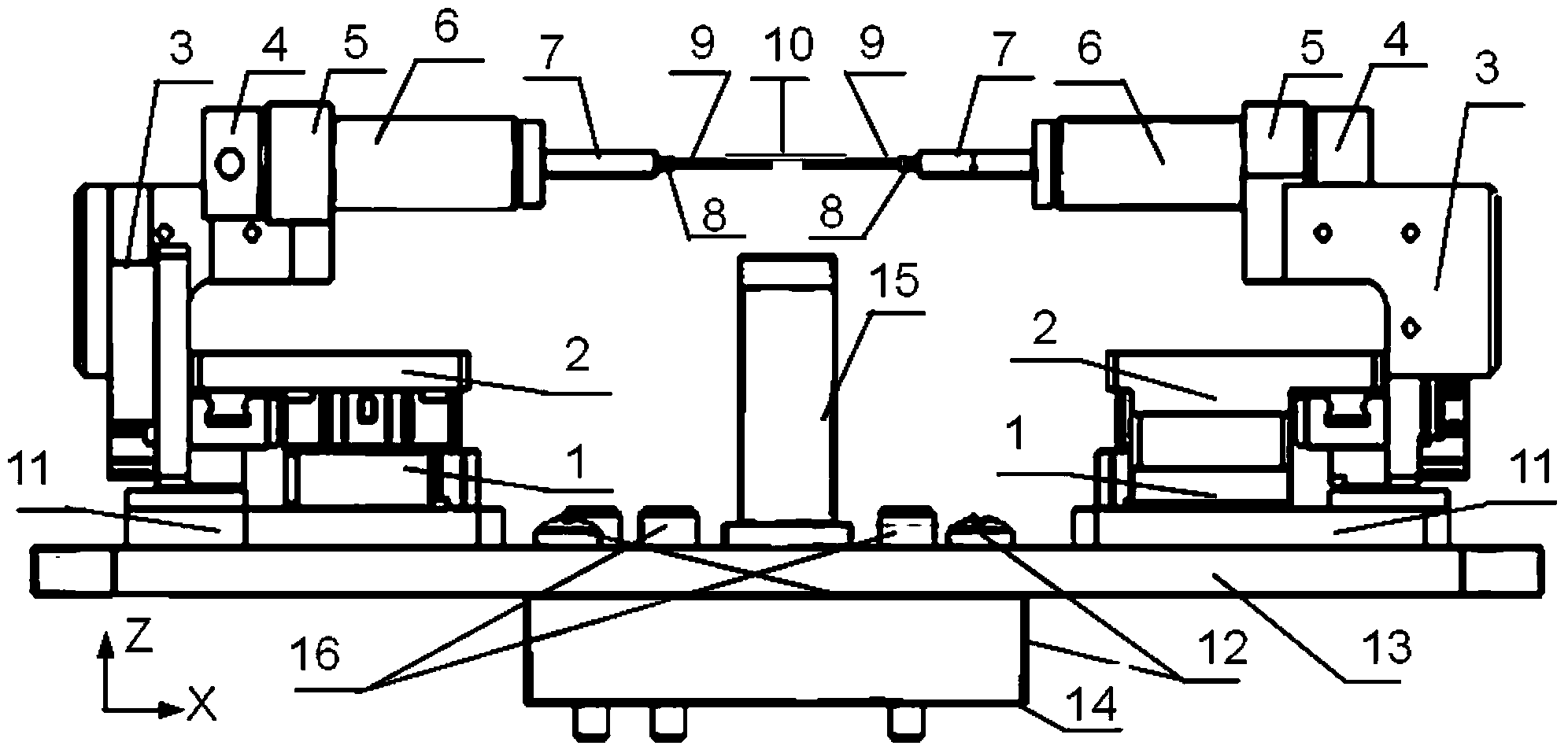

[0026] The present invention provides a kind of uniaxial bidirectional micromechanical measurement device and measurement method for scanning microenvironment. The uniaxial bidirectional tension detection under SEM microsystem is taken as an example below, and the principles and details of the present invention are explained in conjunction with the accompanying drawings. The structure and tensile testing method are further explained.

[0027] Such as figure 1 As shown, the overall support unit 13 is a rectangular aluminum alloy plate (175mm×95mm×7mm), the surface is sprayed with silver metallic paint, the overall support unit 13 is installed on the base 14 of the SEM sample stage, and there are two positioning pins between the two 16. Three M4-20 inner hexagonal screws 12 are connected. A circular hole with a diameter of 48 mm is provided at the center of the upper surface of the integral support unit 13, and the SEM sample stage 15 passes through the central circular hole of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com