Cantilever framework supporting structure protruding out of outer side of building and construction method of cantilever framework supporting structure

A technology for supporting structures and buildings, applied in building construction, building, housing structure support, etc., can solve major safety accidents, dangers of high-altitude operations, construction difficulties, etc., to ensure stability, improve safety, and improve strength. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

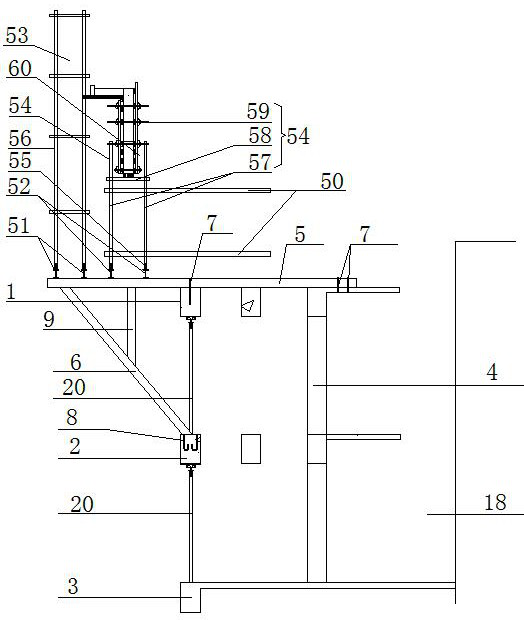

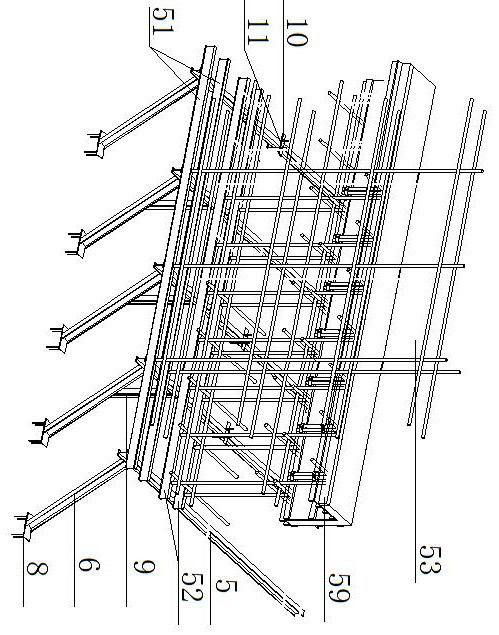

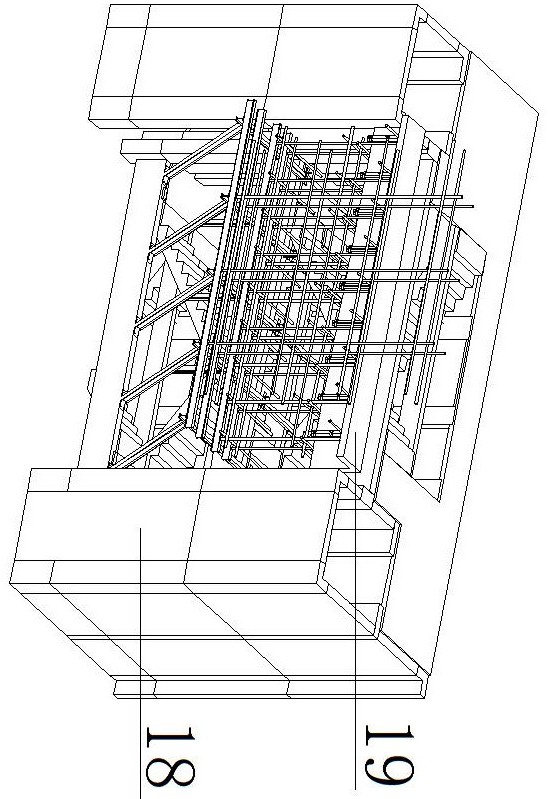

[0055] Embodiment 1: as Figure 1 to Figure 7 A cantilever frame support structure protruding from the outside of the building is shown, including the upper side beam 1 of the stairs, the middle side beam 2 of the stairs, the lower side beam 3 of the stairs and the internal wall 4 of the building, and also includes the horizontal I-beam 5 and the oblique I-beam 6. A plurality of horizontal I-beams 5 are arranged side by side along the length direction of the upper side beam 1 of the stairs and on the upper side beam 1 of the stairs and the inner wall 4 of the building. The front end of each horizontal I-beam 5 is connected to the Slanted I-beams 6 are arranged between side beams 2 in the staircase; along the length direction of the upper side beams 1 of the stairs and at the front end of the top of the horizontal I-beams 5, I-beam groups A51 and I-beams are welded side by side. Group B52, the top of the I-shaped steel group A51 is welded with a maintenance scaffold 53, and the...

Embodiment 2

[0075] Embodiment 2: the height of the maintenance scaffold 53 mentioned in the present invention is higher than the height 2m of the cantilevered frame mold 59, which helps the construction personnel to work safely. Wherein, the I-beams and steel pipes involved only use the commonly used No. 16 I-beam, steel pipe and other conventional materials can complete the construction of the cantilever frame, which saves costs and facilitates construction.

Embodiment 3

[0076] Embodiment 3: In order to ensure the construction safety of the main body of the building, an exterior wall scaffold 70 needs to be erected against the building exterior. The inner side of the exterior wall scaffold 70 is 0.3m away from the wall, and the width of the exterior wall scaffold 70 is 1m. In addition, the maintenance scaffold 53 The horizontal steel pipes M56 on the left and right sides are fixed together with the external wall scaffolding 70 on the left and right sides, which can form a safe, effective and complete suspension beam frame system, thereby ensuring the safety of construction personnel during the construction of the external maintenance scaffolding 70 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com