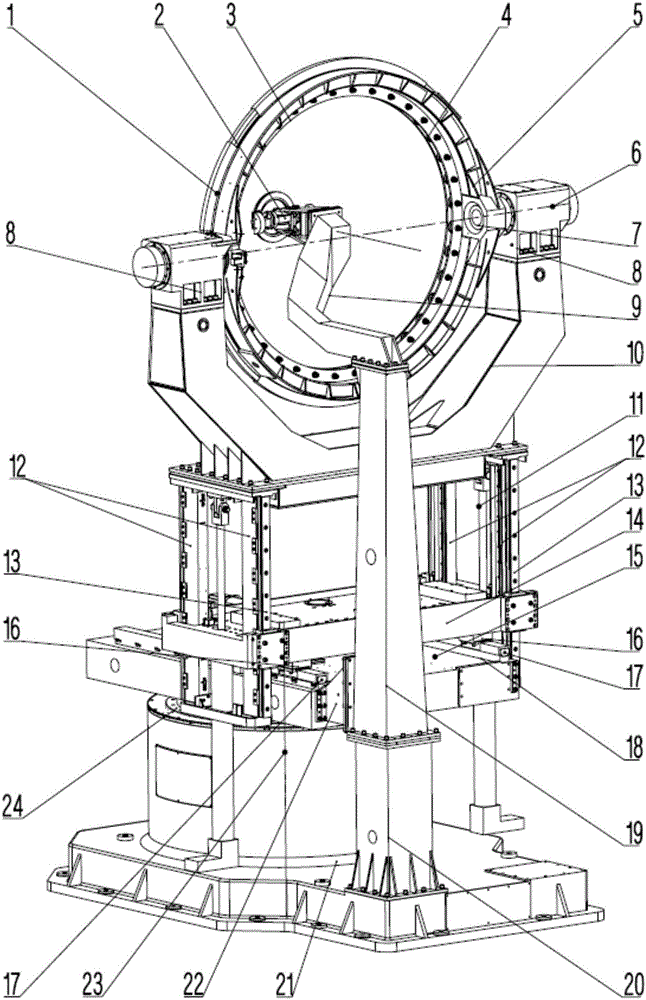

Eight-axis turntable for electromagnetic window testing

A three-axis turntable and electromagnetic technology, applied in the mechanical field, can solve the problems of large data errors and inability to accurately reflect the electrical performance characteristics of electromagnetic window products.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

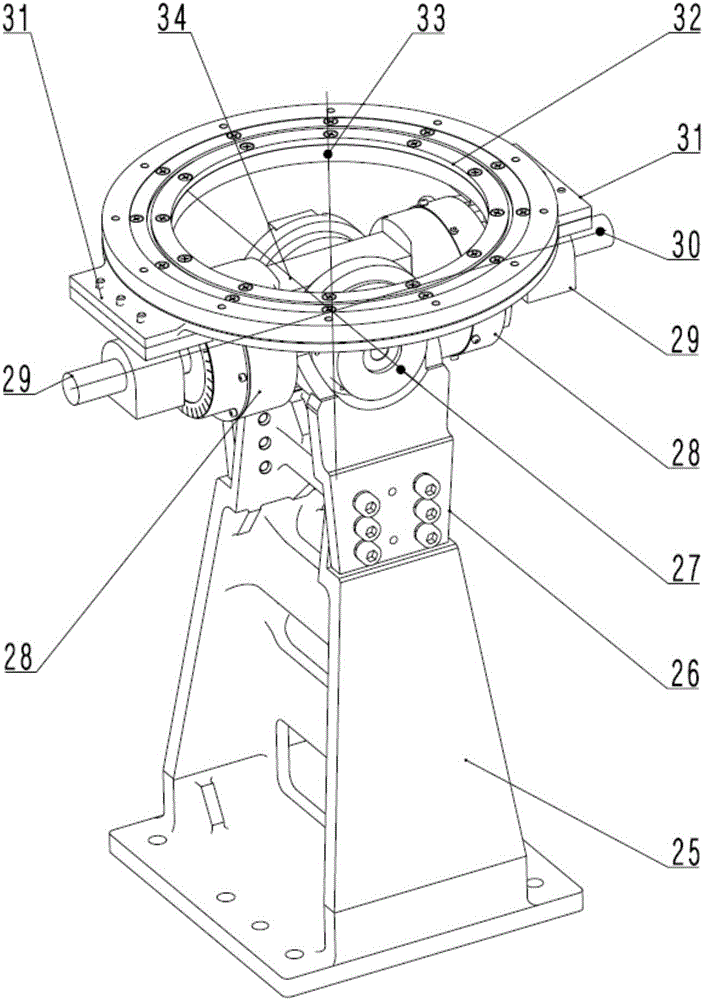

[0023] like figure 1 As shown: the turntable includes a rolling ring assembly 1, a pitch assembly 6, a vertical linear assembly 11, a front and rear linear assembly 15, and an azimuth assembly 23. The electromagnetic window product to be tested is installed on the rolling ring 3 of the rolling ring assembly 1. Supported by a plurality of eccentric wheels 4, the eccentric wheels 4 are installed on the rolling ring seat 5, and the rolling ring seat 5 is connected with a pitch shaft 7 on the left and right, and the pitch shaft 7 is supported by a pair of angular contact ball bearings to form a pitch shaft system. The pitching shaft system is installed on the pitching base 8, and the pitching base 8 is mounted on the pitching frame 10 to realize the pitching and rotating motion of the electromagnetic window product under test. 12 is supported by the rolling linear guide rail 13 and installed on the column plate 14 in the upper and lower linear assembly 11 to realize the vertical m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com