Earth pressure box burying device and method for fill engineering

An earth pressure cell and engineering technology, applied in the direction of measuring devices, measuring forces, instruments, etc., can solve problems such as failure and large errors in monitoring data, and achieve the effects of reducing errors, convenient operation, and easy mass production.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

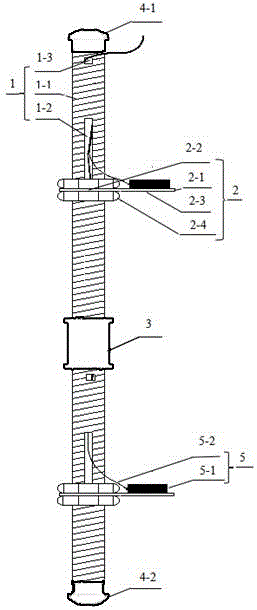

[0040] The earth pressure box embedding method process of the newly built subgrade earth pressure box embedding device is as follows:

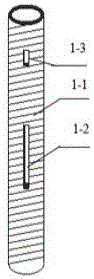

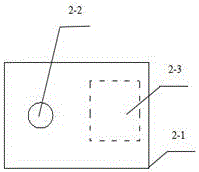

[0041] When the filling project is carried out, first take a section of connecting rod 1, seal the bottom of the hollow threaded rod 1-1 with a sealing cover 4-2, bury the sealed connecting rod 1 in the soil to a certain depth, and weld it to the box. The earth pressure box 5 in the box setting area 2-3 of the disk 2 is connected with the connecting rod 1 through the positioning hole 2-2 on the rectangular disk 2-1 as a whole, and then adjusted to the measurement depth with the positioning nut 2-4 and fixed, and the earth pressure The wires on the box 5 are drawn from the inside of the connecting rod 1 through the part of the wire hole 1-2 in the connecting rod 1. After the filling of this layer is completed, connect the next connecting rod 1 with the sleeve 3, and install the next one that has been welded to the place. For the earth pressure ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com