Novel fiber hydrophone sound-sensitive structure and realization method thereof

An optical fiber and hydrophone technology, applied in the field of underwater acoustic detection, can solve the problems of complex manufacturing process, rupture, and reduced sound pressure sensitivity, and achieve the effects of convenient production, low cost, and improved sound pressure sensitivity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

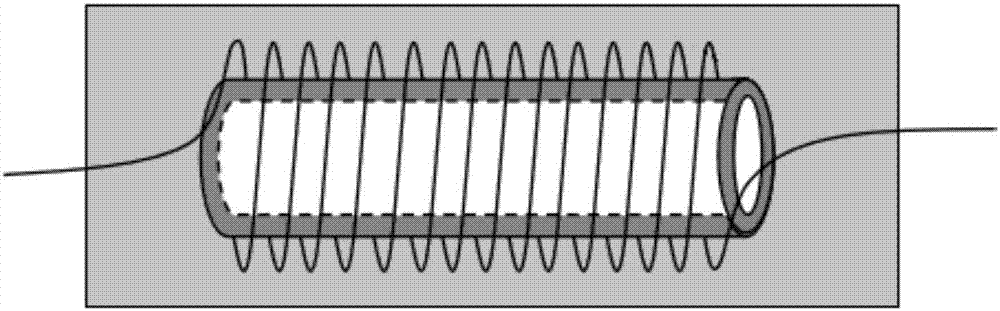

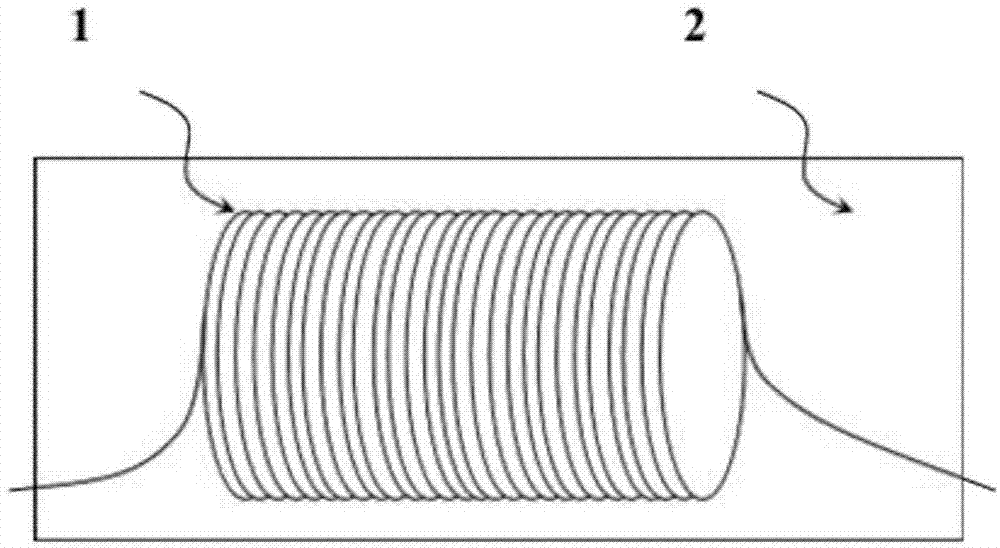

[0022] As an embodiment of the present invention, the optical fiber coil (1) is wound by a small mode field optical fiber with a cladding outer diameter of 80 μm; the polymer material (2) is a polyurethane material, and the acoustic sensitive structure includes a cylindrical A coiled optical fiber coil 1 and a polymer material 2, the optical fiber coil 1 has a cylindrical coiled structure, the optical fiber coil 1 is fixed inside the polymer material 2, and the acoustic sensitive structure is an axisymmetric solid elastic body structure .

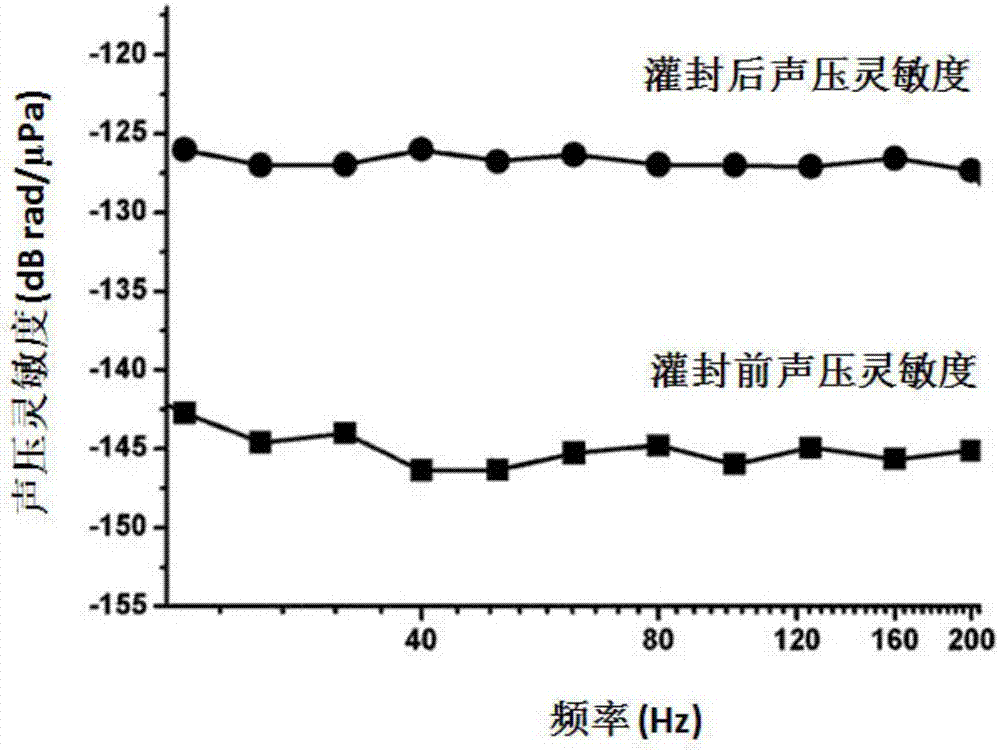

[0023] During production, the polyurethane material (2) is used for potting and curing to form an elastic cylinder with a diameter of Ф20mm and a length of 60mm; a 25m small-mode-field optical fiber is uniformly wound on the elastic cylinder by a constant tension method to form an optical fiber coil (1); Then the sound pressure sensitivity of the optical fiber coil (1) measured by the sound field standing wave method is -146dB rad / μPa; then...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com