Gear double-face engagement precise detection device

A detection device and double-sided technology, applied in the direction of measuring devices, instruments, etc., can solve the problems of low measurement sensitivity, complex structure of the whole machine, large frictional resistance, etc., and achieve the effects of high measurement accuracy, novel principle and improved efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] In order to enable those skilled in the art to better understand the technical solutions of the present invention, the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

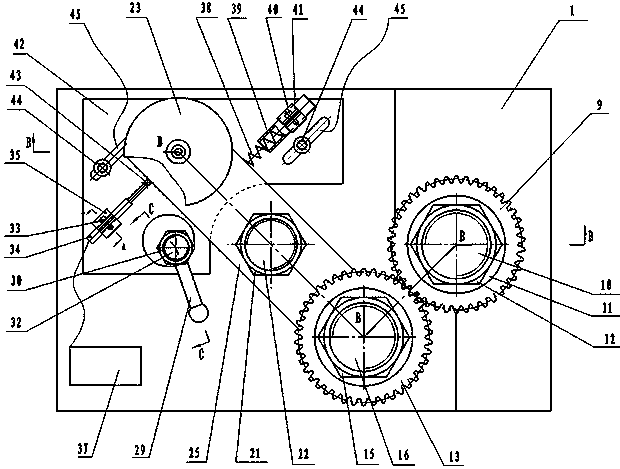

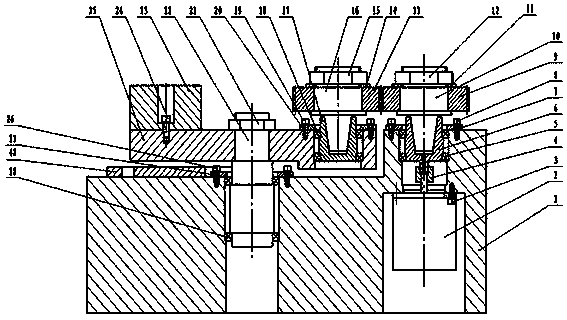

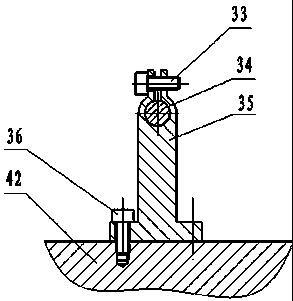

[0022] Please refer to figure 1 , figure 2 , a gear double-sided meshing precision detection device, including a machine base 1, on which a measuring assembly, a measured assembly, a position adjustment device and a measuring assembly are arranged, the measuring assembly includes a driving shaft 6, a driving shaft 6 It is connected with the motor 2, and its action end is equipped with a standard gear 9. The tested assembly includes a driven shaft 17, and the tested assembly is composed of a swing shaft 22 and a swing frame 25 horizontally erected on the swing shaft 22. One end of the swing frame 25 is equipped with a driven shaft 17, and the other end is equipped with a balance weight 23. The driving shaft 6, the d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com