High-efficiency winding method for inhibiting temperature error of fiber gyro coil

A fiber optic gyroscope and temperature error technology, which is applied to Sagnac effect gyroscopes, measuring devices, instruments, etc., can solve the problem of degrading the temperature performance of high-precision fiber optic gyroscopes, large temperature errors of fiber optic rings, and reducing the actual detection accuracy of fiber optic gyroscopes And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings; it should be noted that the embodiments are illustrative, not restrictive, and cannot limit the protection scope of the present invention.

[0016] In order to better understand the technical solution of the present invention, the existing common winding methods are firstly explained:

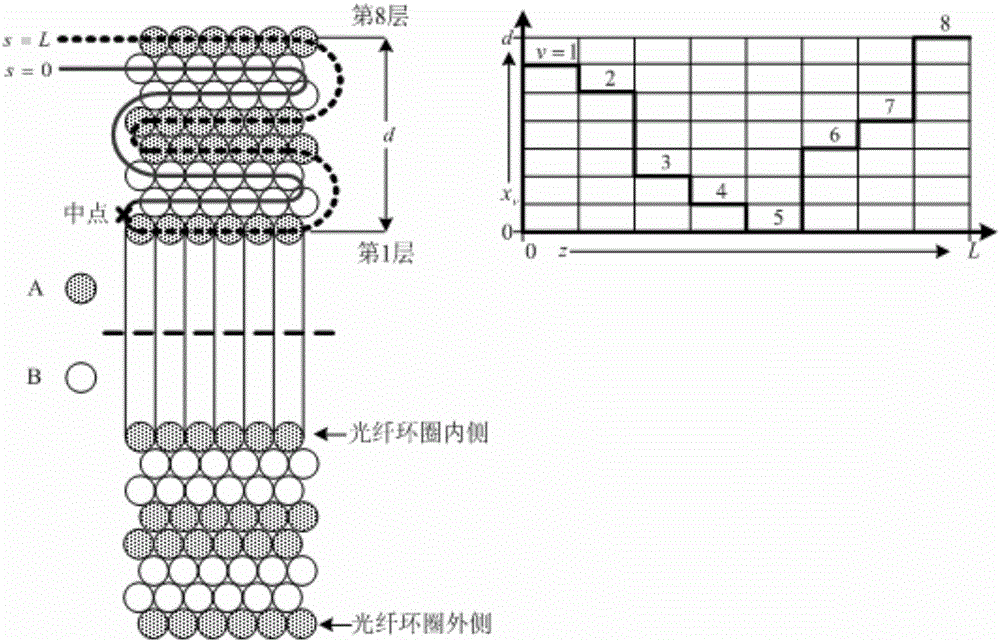

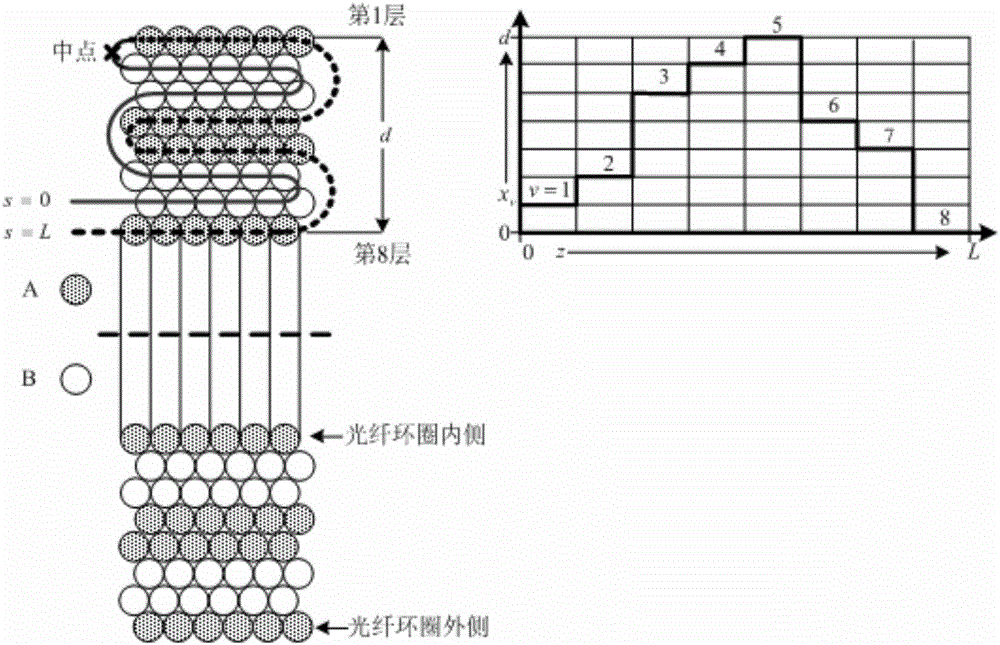

[0017] When the optical fiber ring is wound, an optical fiber is divided into two equal sections A and B from the midpoint, and they are wound on two fiber supply wheels in advance (such as figure 1 shown), fix the midpoint of the optical fiber at the intersection of the axle and the rim of the bobbin. Such as figure 2 As shown, for the traditional quadrupole symmetrical winding method, fiber A winds the first layer of the fiber ring longitudinally along the wheel shaft, fiber B winds the second layer of the fiber ring longitudinally along the wheel shaft, and then ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com