Multi-physical measurement sensor chip and production method thereof

A sensor chip, multi-physical quantity technology, applied in the direction of fluid pressure measurement, force measurement, and heat measurement by changing ohmic resistance, can solve problems such as low resistance change rate ΔR/R, thin film thickness, complex preparation process, etc. Achieve the effects of excellent temperature characteristics, low power consumption, and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

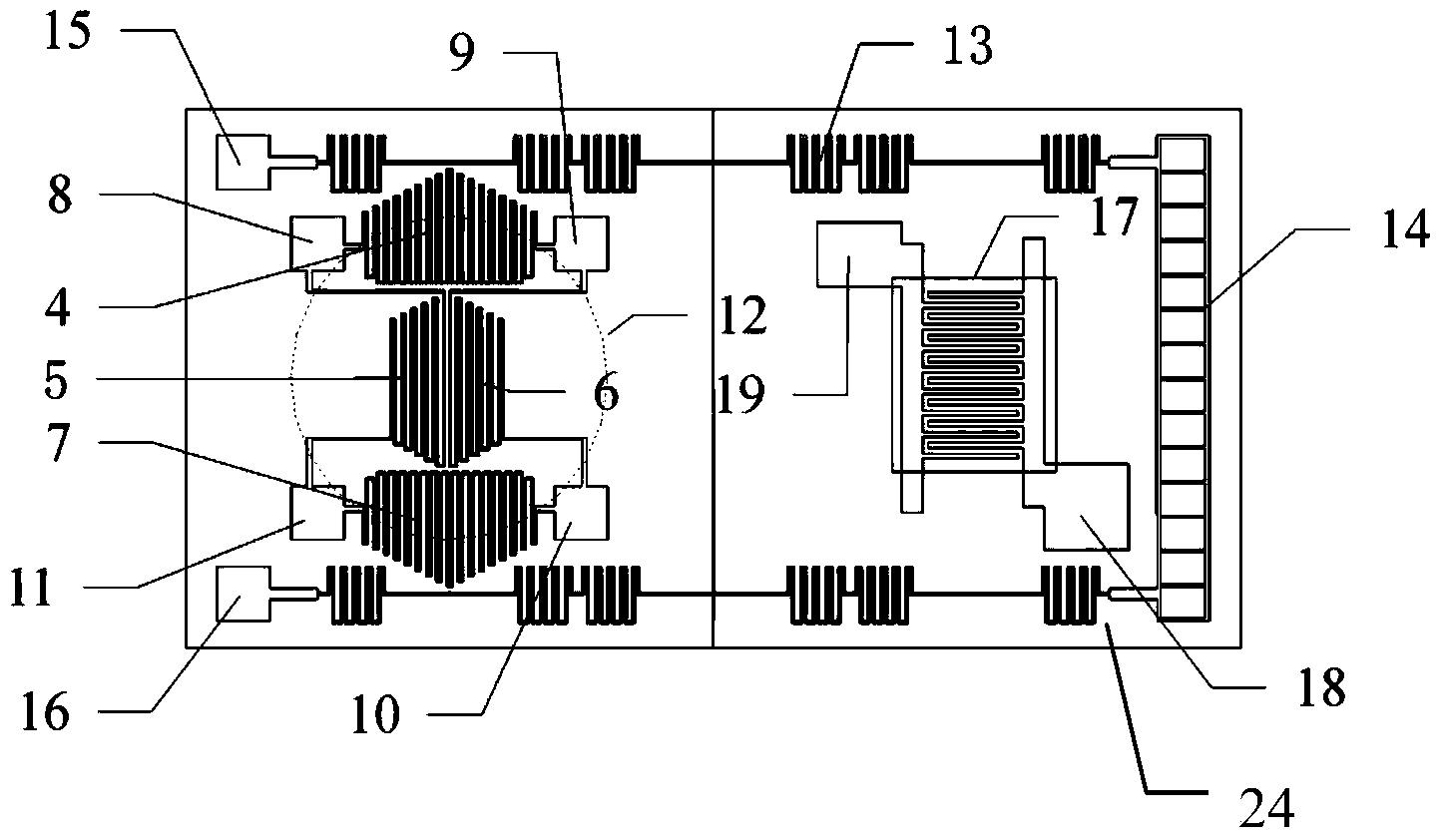

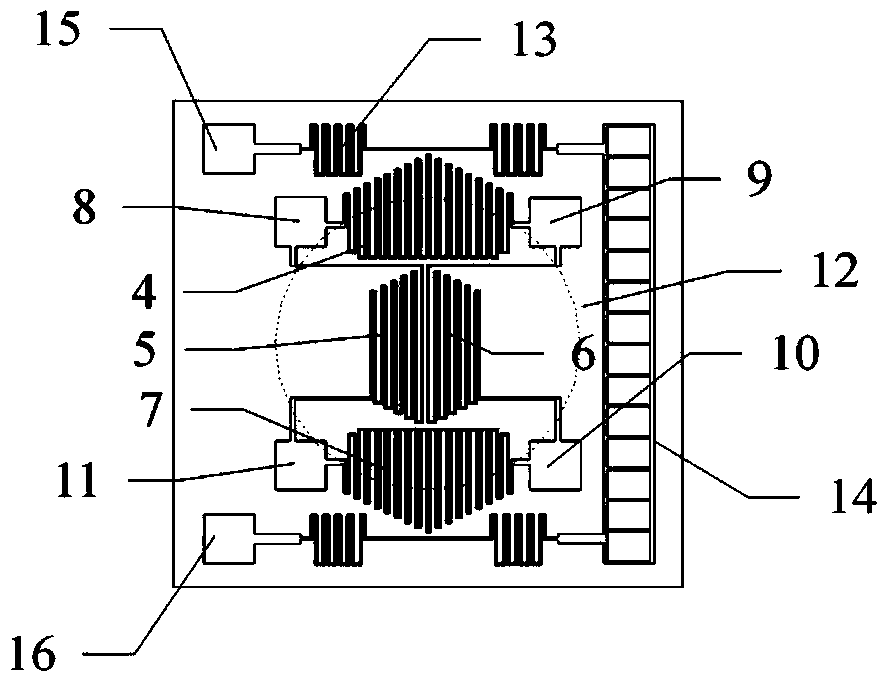

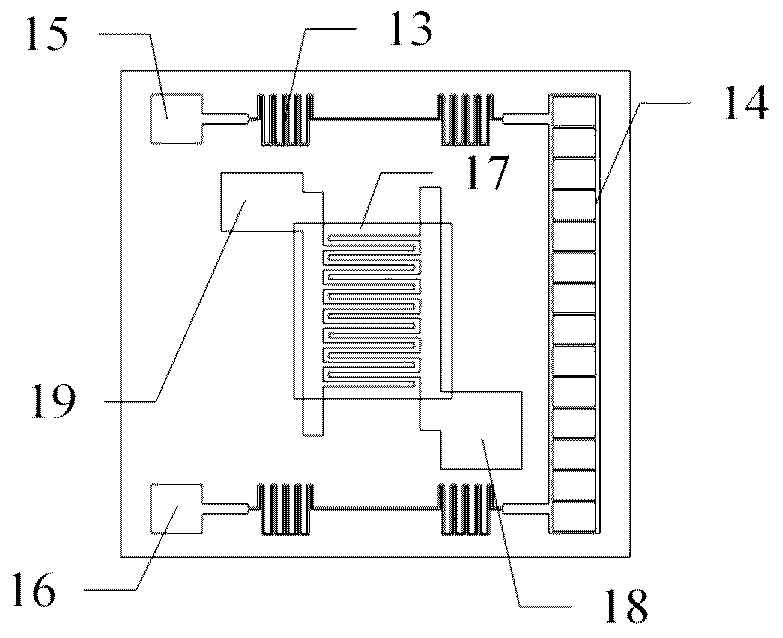

[0044] figure 1 It is a schematic structural diagram of the sensor chip integrating temperature, humidity and pressure measurement of the present invention. The sensor chip includes a substrate 24 and a pressure sensor, a humidity sensor and a temperature sensor integrated on different parts of the substrate 24. A microcavity 12 is etched on the back of the substrate 24 at a position corresponding to the pressure sensor. The microcavity 12 It can be vacuum sealed and can be used to measure absolute pressure at this time. Gauge pressure can also be measured by filling it with dry air at one atmosphere. In addition, the microcavity 12 may not be sealed and can be used to measure the differential pressure. The structure of the pressure sensor is as image 3As shown, it includes a Wheatstone bridge. In this example, the Wheatstone bridge is a full bridge structure, which is composed of four first resistance elements 4-7 electrically connected, wherein the first resistance eleme...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com