Optical module with fiber winding mechanism

An optical module and optical fiber technology, which is applied in the field of optical communication, can solve the problems of the fiber coiling mechanism occupying the module space, the difficulty in the operation of the coiling process, and the performance impact of the optical module, so as to save internal space, the coiling process is simple and easy, and the operation process Simple and understandable effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

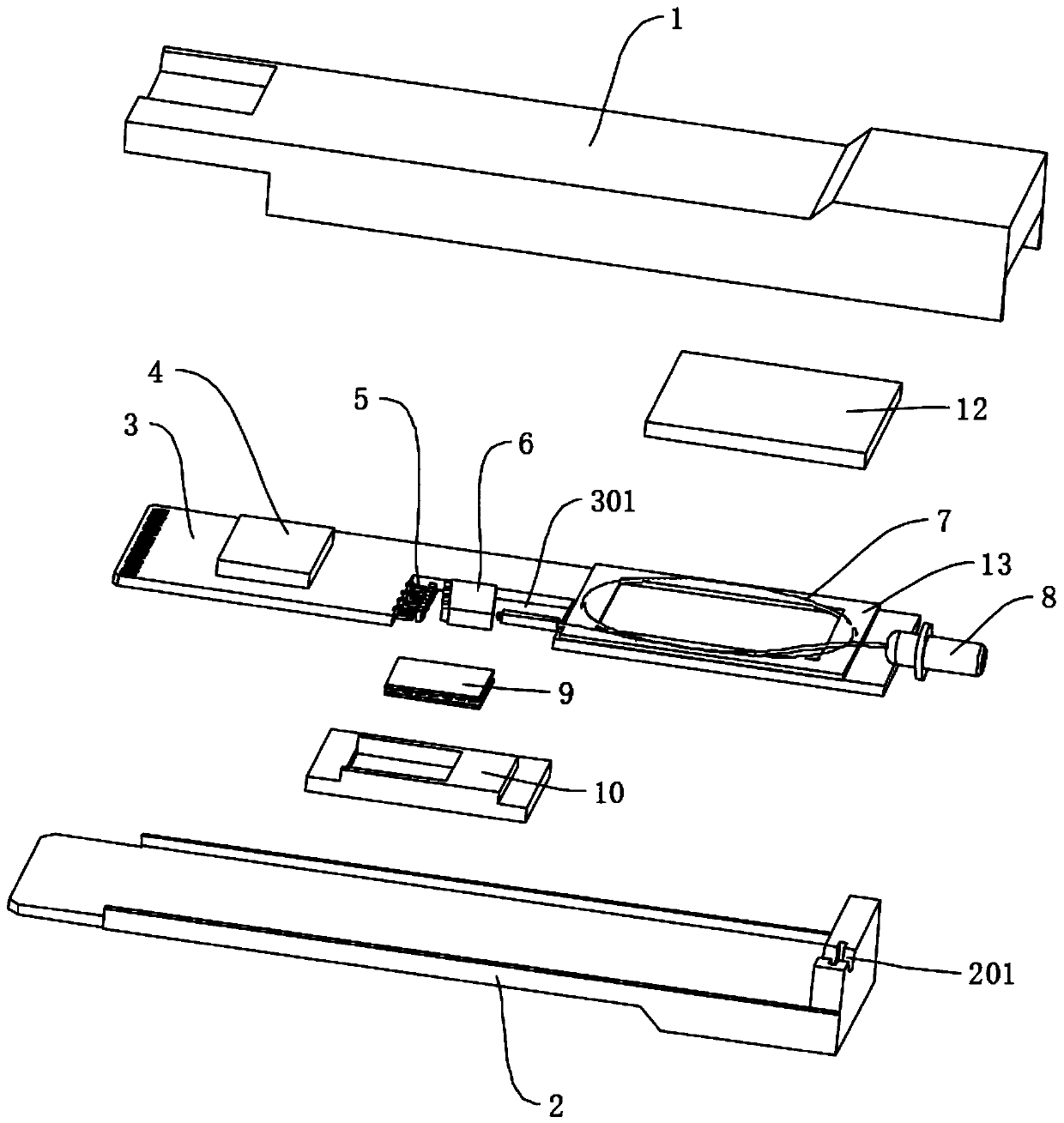

[0026] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the drawings in the embodiments of the present invention.

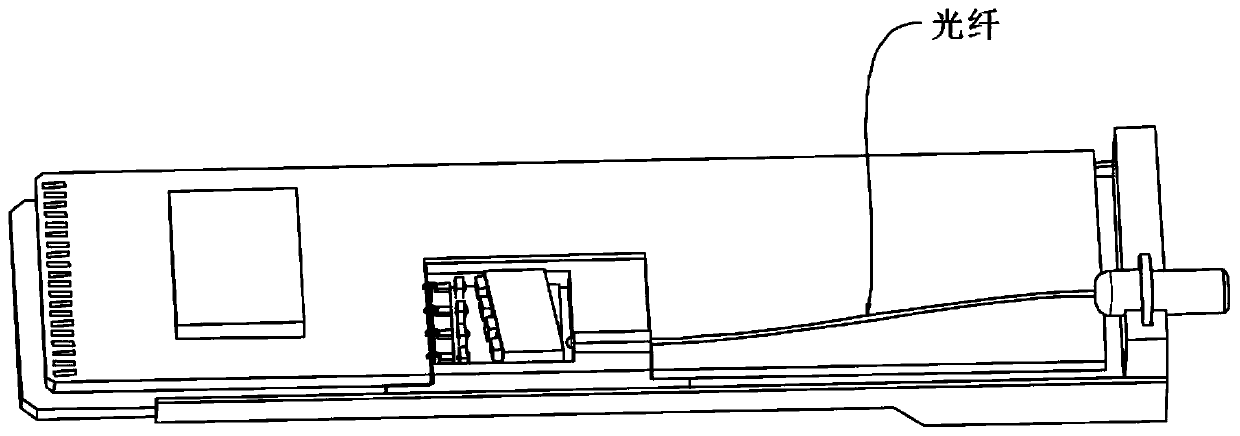

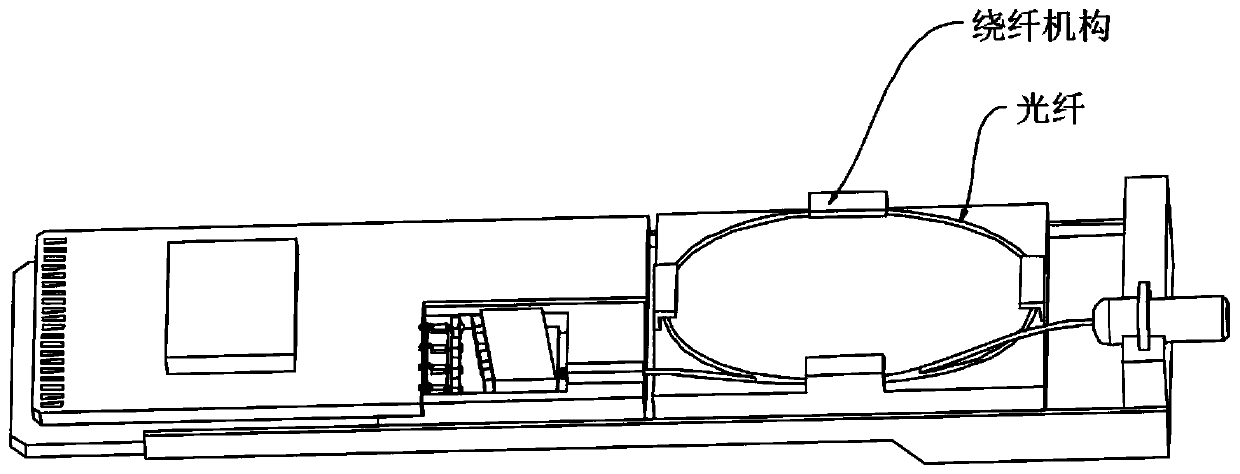

[0027] See Figure 3 to Figure 7 , an optical module with a fiber winding mechanism of the present invention, including an upper heat dissipation housing 1, a lower heat dissipation housing 2 and a PCB circuit board arranged in the upper heat dissipation housing 1 and the lower heat dissipation housing 2, which can be spliced into one 3. The PCB circuit board 3 is provided with a control chip 4, the PCB circuit board 3 is connected to a laser 5 through a bonded gold wire, the front side of the laser 5 is provided with an optical device 6, the optical device 6 is connected to an optical fiber 7, and the other end of the optical fiber 7 The optical head 8 is connected, the laser 5 and the optical device 6 are respectively arranged on the TEC cooler 9, the TEC cooler 9 is insta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com