Method for preparing sensitive coil of reflection type optical fiber current sensor

A fiber optic current and sensitive coil technology, applied in the direction of voltage/current isolation, measuring current/voltage, instruments, etc., can solve the problems that the optical fiber cannot be completely fixed, the stress of the sensitive optical fiber is large, and the coefficient of linear expansion is large, so as to avoid errors and resist Good shock vibration performance and stress uniform effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

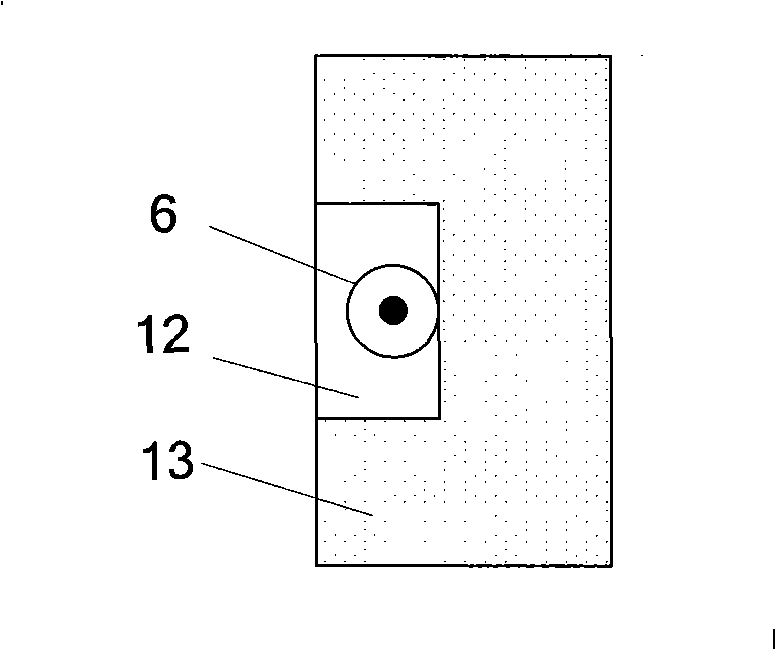

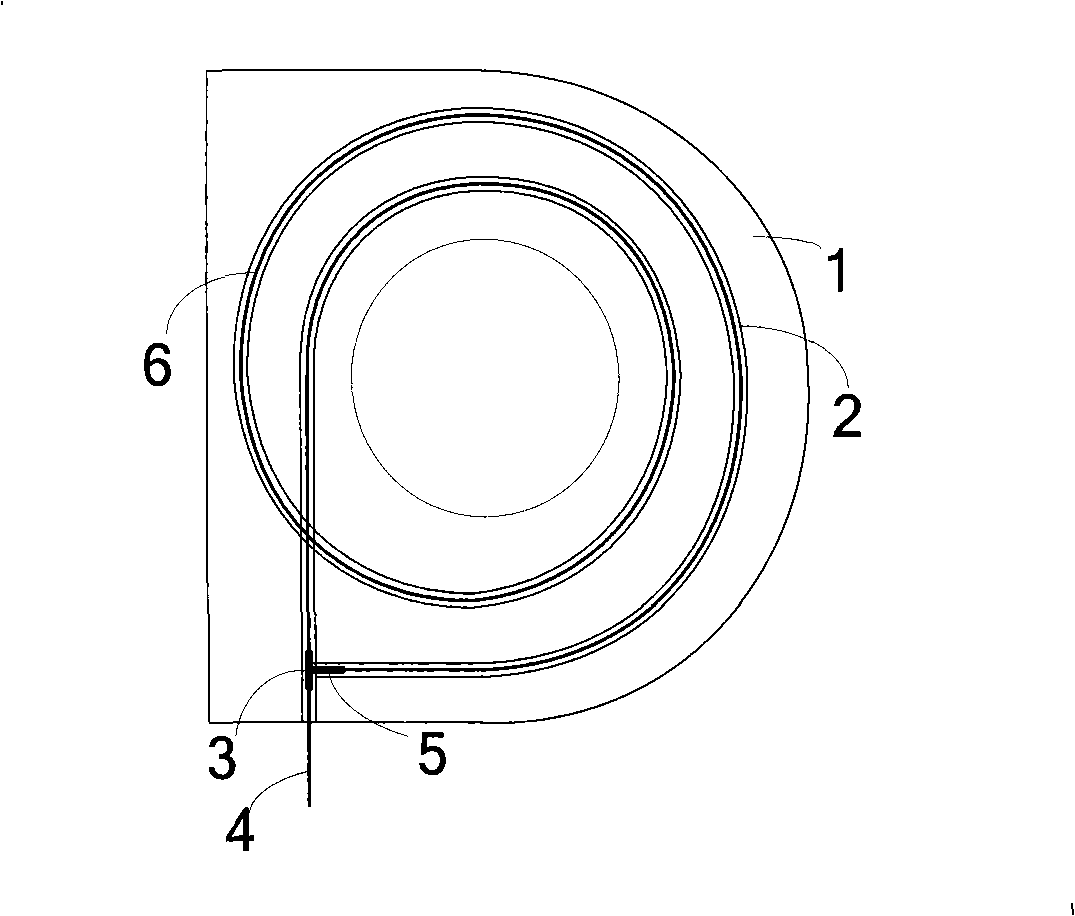

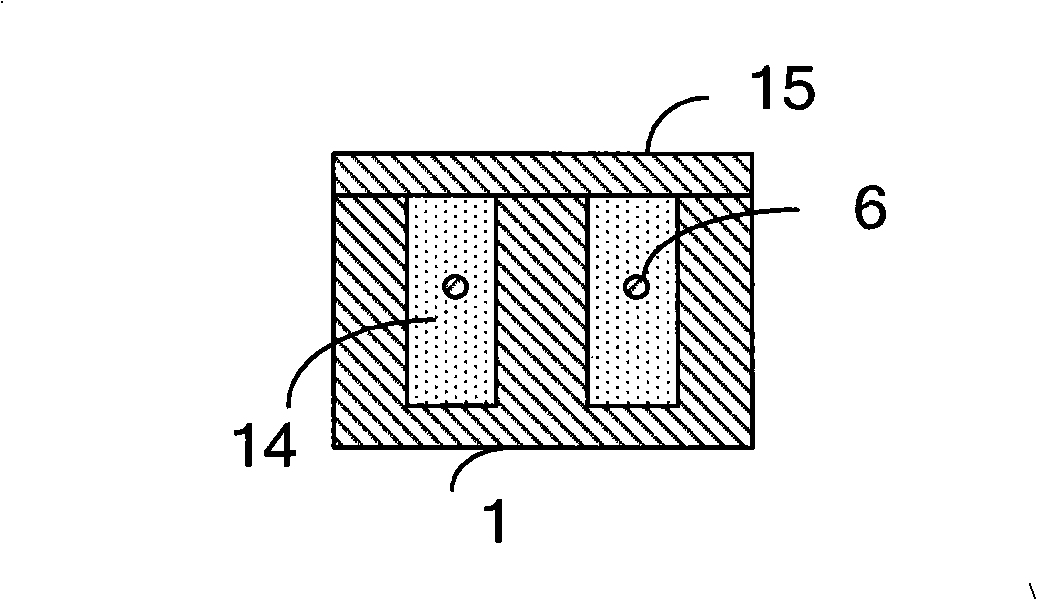

[0025] Such as figure 2 As shown, the present invention uses aluminum alloy with relatively low density and low cost to process the annular sensitive coil bobbin 1, and the surface of the coil bobbin 1 is anodized to avoid the influence of metal oxidation on the coil. A groove 2 shaped as an Archimedes spiral is processed on the coil bobbin, its radial cross-section is trapezoidal or rectangular, the groove depth is 1-5mm, the groove width is 1-5mm, the groove spacing is 2-10mm, and the groove depth is generally selected 2mm, groove width 2mm, groove spacing 4mm. The circumferential shape of the groove 2 is an Archimedes spiral, and there are tangent extensions at the beginning and the end of the spiral, and they intersect vertically.

[0026] During processing, use a syringe with a smaller outlet to apply the optical fiber paste in the groove 2, with a height of 0.8-1.2mm, and use a tool that can only extend into the groove 2 for 0.8-1.2mm to scrape the optical fiber paste ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Groove depth | aaaaa | aaaaa |

| Groove width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com