Compound material special piece molding method and molding central spindle

A technology of special-shaped pipe fittings and forming method, which is applied in the direction of tubular articles, other household appliances, household appliances, etc., can solve the problems of poor overall appearance, laboriousness, and increased weight of the frame.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

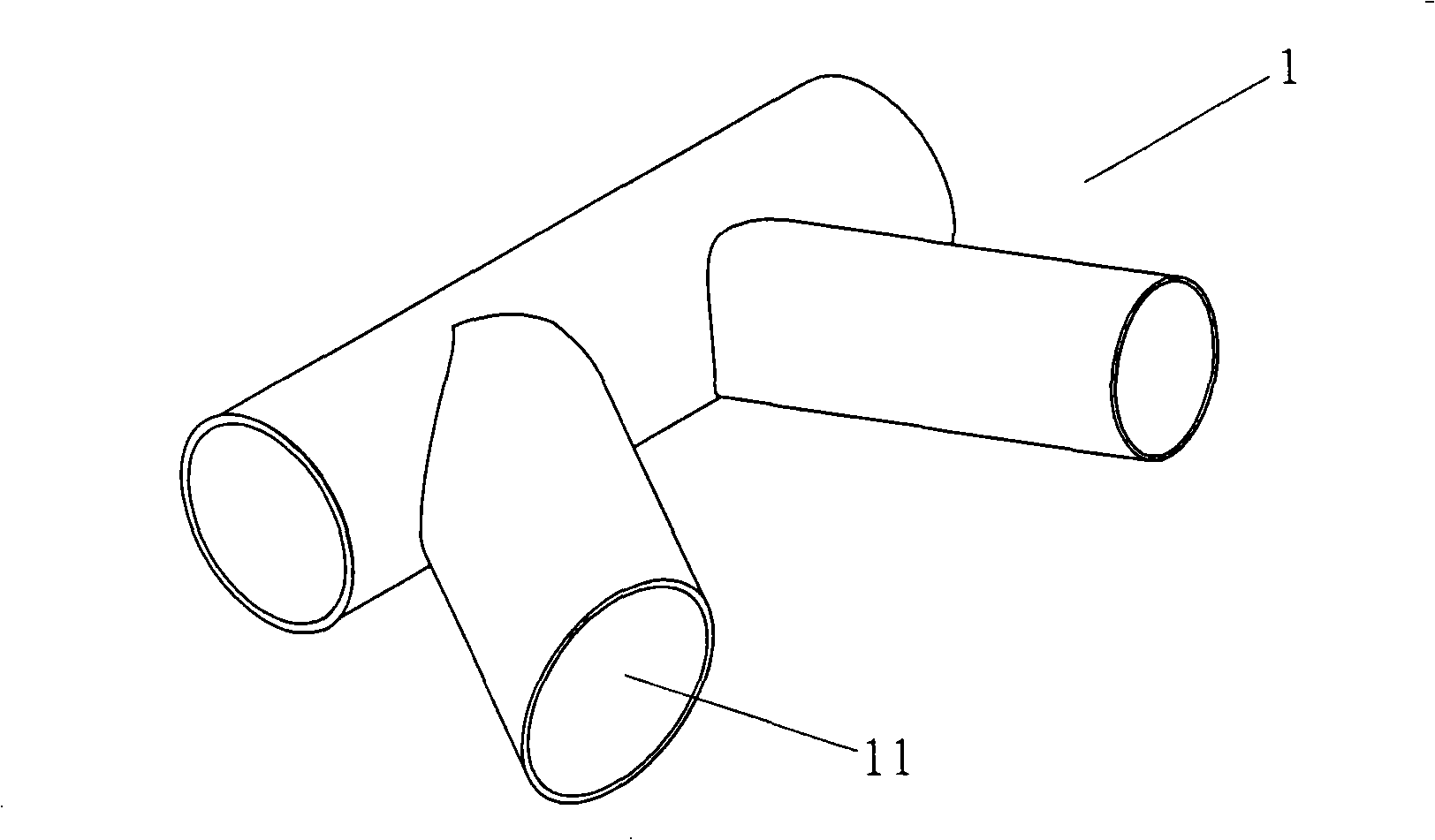

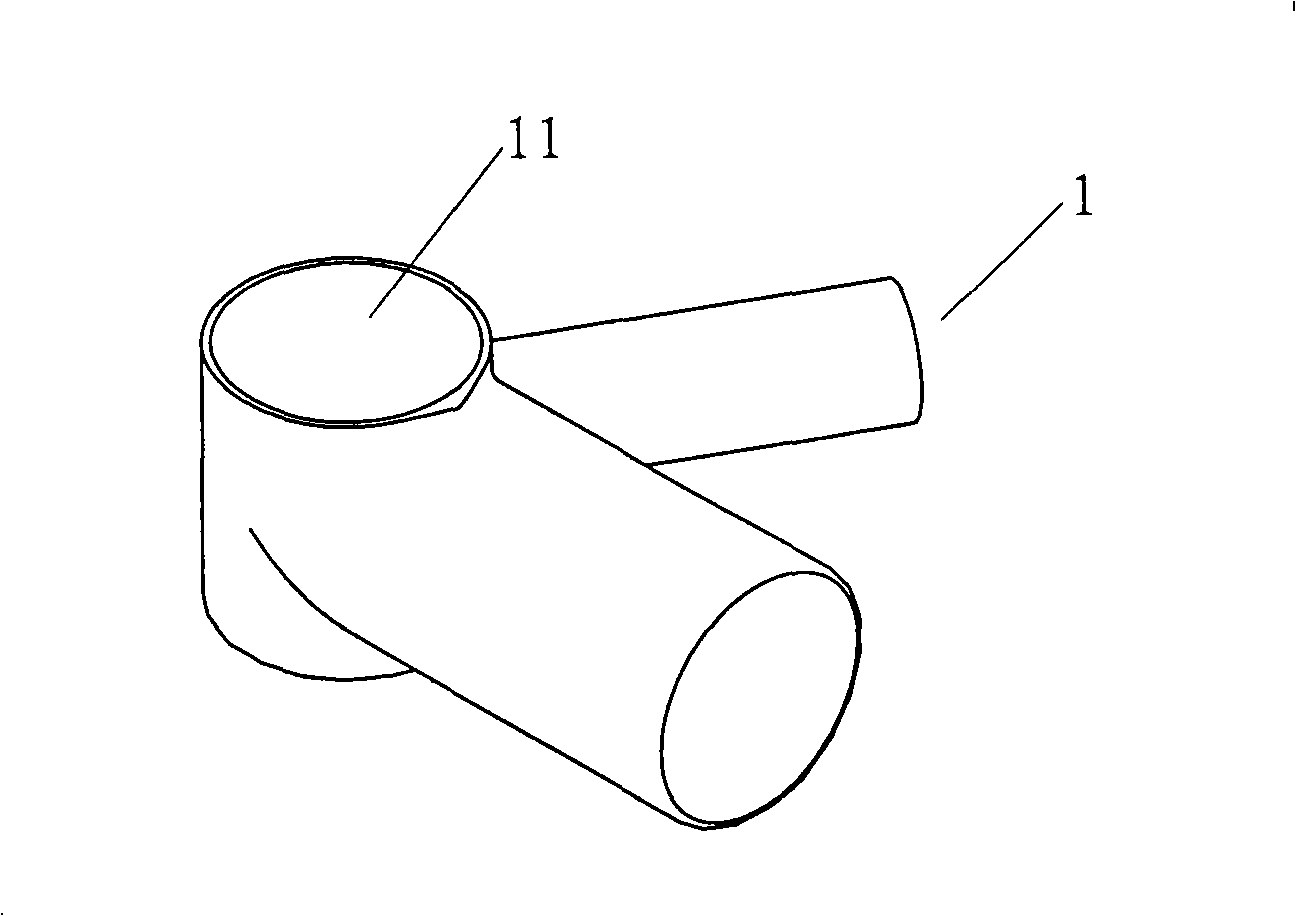

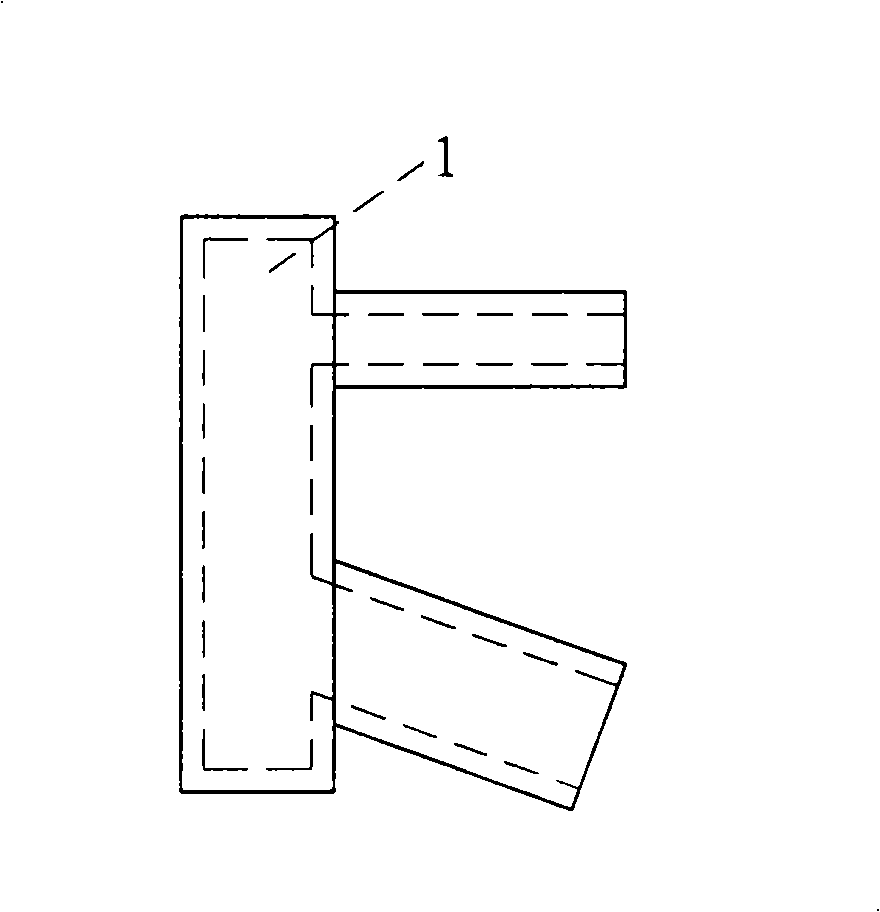

[0024] The present invention is described with the special-shaped pipe fitting of bicycle frame, as shown in Figure 1 to Figure 4, the molding process of this special-shaped pipe fitting:

[0025] Such as Figure 1A , 1B Shown, at first match the shape of the special-shaped pipe place of bicycle rack to be molded with supporting mandrel 1, this supporting mandrel 1 is by the PE (polyethylene) material or HDPE (high-density polyethylene) of material with low softening temperature and high melting point The material adopts hollow blow molding to form a support tube of a tubular body. The softening temperature of the support tube material is lower than 65 degrees Celsius, and the melting temperature is higher than 200 degrees Celsius. The inner cavity of the support mandrel 1 is an open cavity 11, so that the air duct can pass through the cavity 11;

[0026] Such as Figure 2A , 2B As shown, secondly, the soft polymer composite carbon fiber yarn sheet is wrapped with the shape...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Softening temperature | aaaaa | aaaaa |

| Melting temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com