Segregation resistant agent for concrete adding naphthalene water reducer and pumping aid of naphthalene water reducer, and preparation method and application thereof

A technology of naphthalene-based water reducer and anti-segregation agent, which is applied in the field of building materials, can solve the problems of unfavorable workability of concrete and loss of fluidity of concrete, and achieve the effect of reducing fluidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] The composition of the anti-segregation agent used in the examples is polycarboxylate water reducer (calculated as solid): water=15.0:85.0. That is, the anti-segregation agent is an aqueous solution with a solid content of 15%.

[0033]Main raw materials used in the examples: cement is 42.5 grade ordinary Portland cement produced by a cement group in Zhejiang. The naphthalene-based water reducer is an aqueous solution (solid content is 30%), the dosage is 2.1% of the amount of the cementitious material, and the concrete water reducing rate is about 24%.

[0034] Mixing water and maintenance water are tap water.

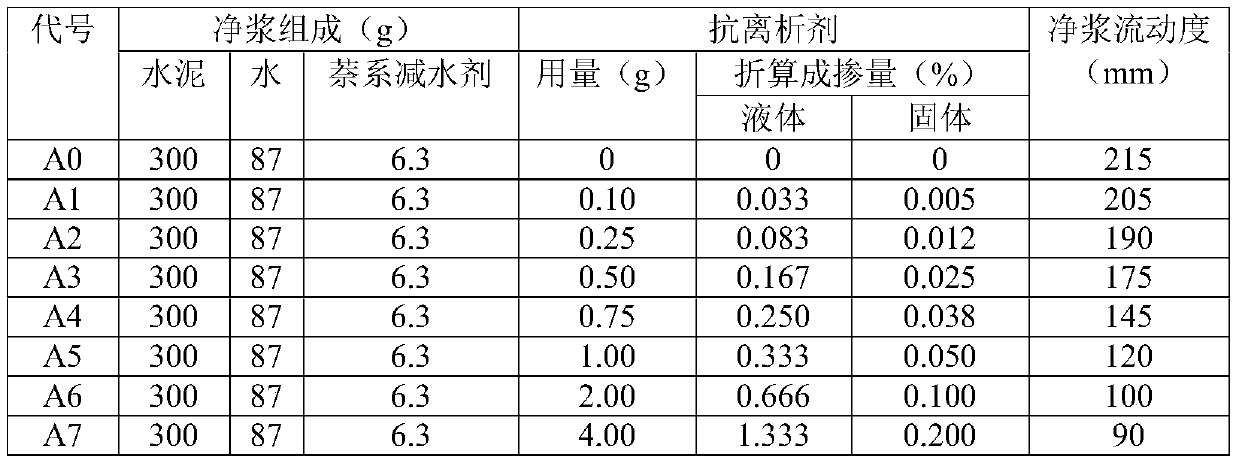

[0035] According to "GB / T 8077-2012 Test Method for Homogeneity of Concrete Admixtures", carry out the test on the change law of slurry fluidity with the amount of anti-segregation agent, and refer to the following table "mixing ratio of series cement slurry (measurement unit is gram or kg)" for raw material weighing.

[0036] The test procedure is to use a ...

Embodiment 2

[0041] The composition of anti-segregation agent used is polycarboxylate water reducer (calculated by solid): triethanolamine (calculated by solid): water=14.5:0.5:85.0. That is, the anti-segregation agent is an aqueous solution with a solid content of 15%.

[0042] Main raw materials used in the examples: cement is 52.5 grade ordinary Portland cement produced by a certain cement group in Zhejiang. The naphthalene-based water reducer is an aqueous solution (solid content is 30%), the dosage is 2.1% of the amount of the cementitious material, and the concrete water reducing rate is about 24%.

[0043] Mixing water and maintenance water are tap water.

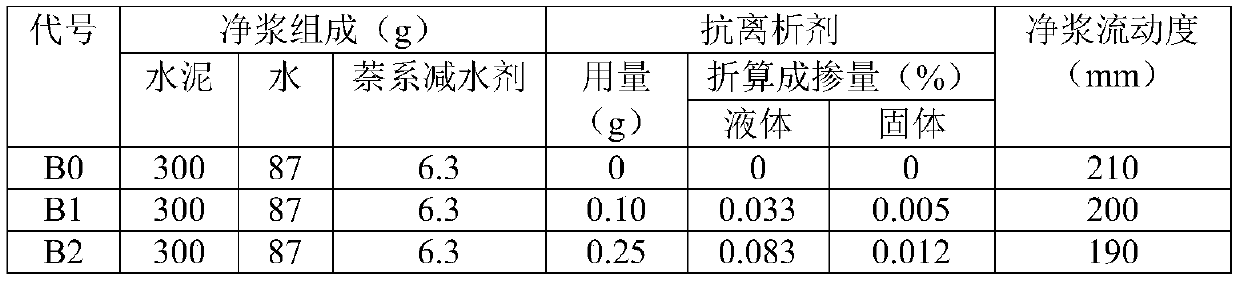

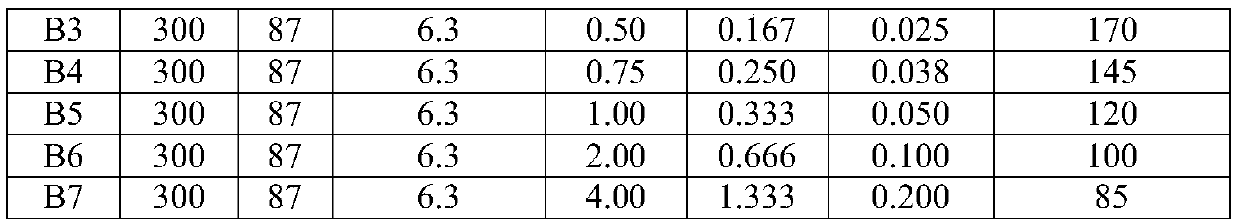

[0044] According to "GB / T 8077-2012 Test Method for Homogeneity of Concrete Admixtures", carry out the test on the change law of slurry fluidity with the amount of anti-segregation agent, and refer to the following table "mixing ratio of series cement slurry (measurement unit is gram or kg)" for raw material weighing.

[0045]...

Embodiment 3

[0051] The anti-segregation agent used in the embodiment consists of polycarboxylate water reducer (in solid): triethanolamine (in solid): silicone defoamer (Dow Corning DC544 in the United States) (in solid): water=14.3: 0.5:0.2:85.0. That is, the anti-segregation agent is an aqueous solution with a solid content of 15%.

[0052] The main raw materials used in the embodiment: cement is 42.5 grade ordinary Portland cement produced by a cement group in Zhejiang, slag is S95 grade slag micropowder, and fly ash is F class II grade fly ash; naphthalene-based water reducer is an aqueous solution ( The solid content is 30%), the dosage is 2.1% of the amount of cementitious material, and the water-reducing rate of concrete is about 24%.

[0053] Mixing water and maintenance water are tap water.

[0054] According to "GB / T 8077-2012 Test Method for Homogeneity of Concrete Admixtures", carry out the test on the change law of slurry fluidity with the amount of anti-segregation agent, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com