Water absorbent swelling resin aggregate concrete and preparation method thereof

A water-swelling and concrete technology, applied in the field of building materials, can solve the problems of low strength, large volume and high water absorption of lightweight aggregates, and achieve the effects of saving concrete solid raw materials, simple preparation process and low production cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

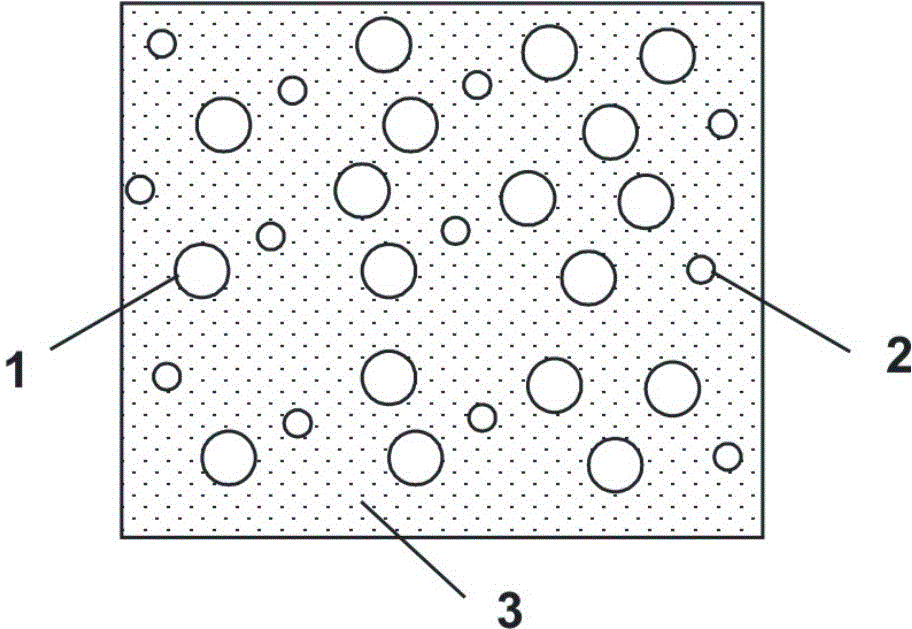

Image

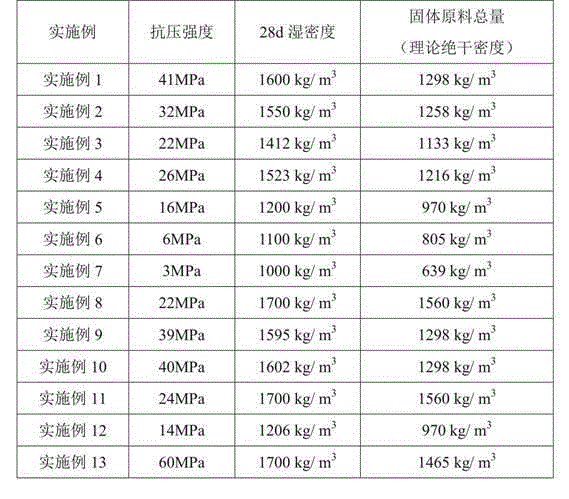

Examples

Embodiment 1

[0028] A water-absorbing resin aggregate concrete, which is made by mixing the following raw materials in parts by weight: 420 parts by weight of cement, 186 parts by weight of admixtures, 125 parts by weight of water-swellable aggregates (after soaking), and 686 parts by weight of fine aggregates Parts by weight, 91 parts by weight of fresh water, 13 parts by weight of water reducing agent, and 2 parts by weight of fiber; the cement strength grade is 42.5, which is composed of 20wt% sulfoaluminate cement and 80wt% ordinary portland cement ; The admixture is composed of 41wt% fly ash, 41wt% slag powder and 18wt% silica fume; the particle size range of the water-absorbing swelling aggregate after soaking treatment is 4 ~ 5mm, 5 ~ 6mm, 7~8mm; the fine aggregate is pottery sand, the maximum particle size is 4.75mm, the apparent density is 1.20g / cm??, and the water absorption rate is 17%; the water reducing agent is polycarboxylic acid Water reducing agent, the water reducing rate...

Embodiment 2

[0037] A water-absorbing resin aggregate concrete, which is mixed with the following raw materials in parts by weight: 419 parts by weight of cement, 187 parts by weight of admixtures, 156 parts by weight of water-absorbing swellable aggregate (after soaking), 644 parts by weight of fine aggregate Parts by weight, 94 parts by weight of fresh water, 12 parts by weight of water reducer, and 2 parts by weight of fiber; the cement strength grade is 42.5, which is composed of 20wt% sulfoaluminate cement and 80wt% ordinary portland cement The admixture is composed of 41% fly ash, 41% slag powder and 18% silica fume; the particle size range (after soaking treatment) of the water-absorbing swelling aggregate is 4 ~ 5mm, 5~6mm, 7~8mm; the fine aggregate is pottery sand, the maximum particle size is 4.75mm, the apparent density is 1.20 g / cm??, and the water absorption rate is 17%; the water reducing agent is polycarboxylate Acid high-efficiency water reducer with a water reducing rate o...

Embodiment 3

[0046] A water-absorbing resin aggregate concrete, which is made by mixing the following raw materials in parts by weight: 420 parts by weight of cement, 186 parts by weight of admixtures, 187 parts by weight of water-absorbing swellable aggregate (after soaking), and 601 parts by weight of fine aggregate Parts by weight, 96 parts by weight of fresh water, 12 parts by weight of water reducing agent, and 2 parts by weight of fiber; the cement strength grade is 42.5, which is compounded by 20wt% sulphoaluminate cement and 80wt% ordinary portland cement The admixture is composed of 41% fly ash, 41% slag powder and 18% silica fume; the particle size range (after soaking treatment) of the water-absorbing swelling aggregate is 4 ~ 5mm, 5~6mm, 7~8mm; the fine aggregate is pottery sand, the maximum particle size is 4.75mm, the apparent density is 1.20 g / cm??, and the water absorption rate is 17%; the water reducing agent is polycarboxylate Acid high-efficiency water reducer with a wat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com