A new type of concrete batching machine

A batching machine, concrete technology, applied in the direction of conveyors, large containers, unloading devices, etc., can solve the problems of reduction, the inability of the guide trough to be adjusted, and the increase of the discharge flow rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

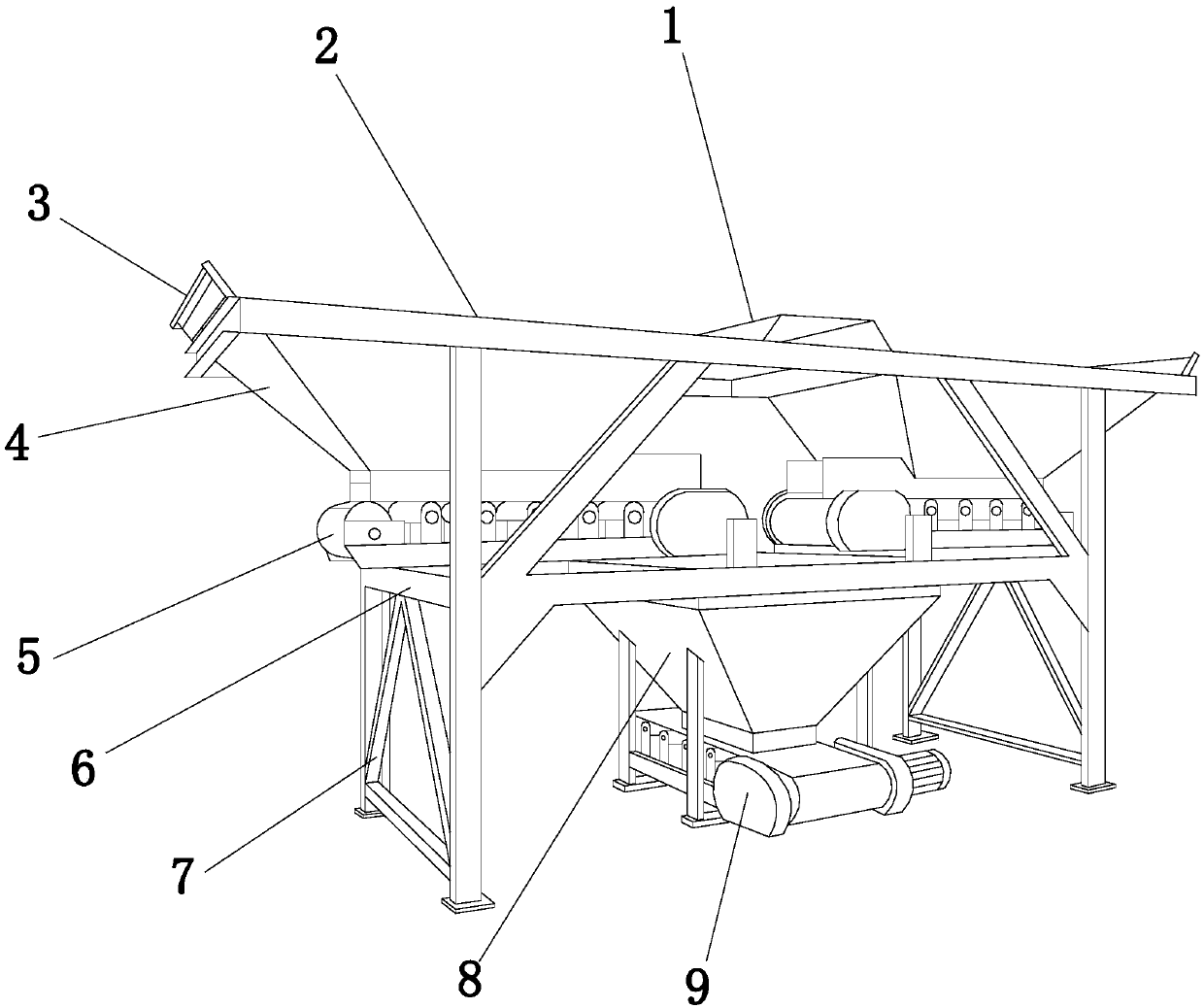

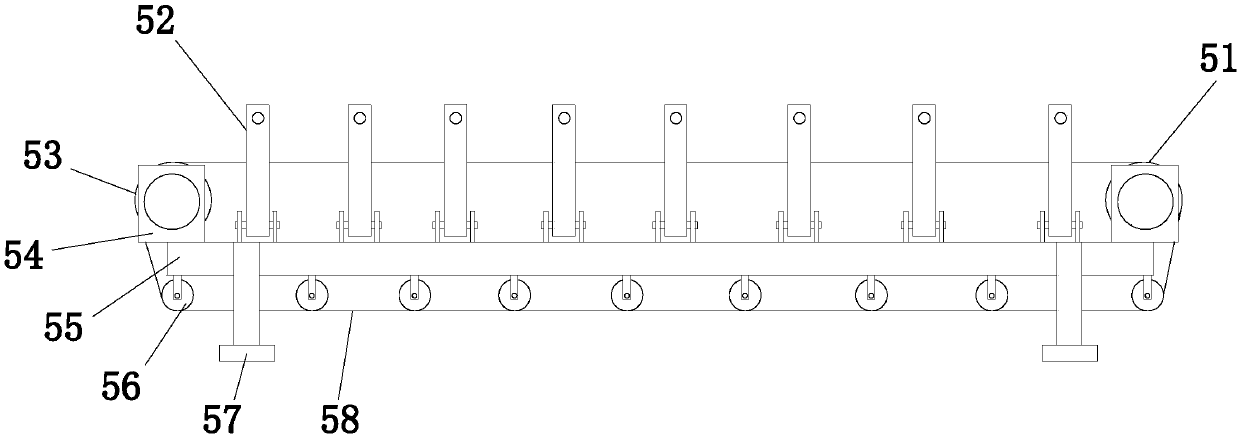

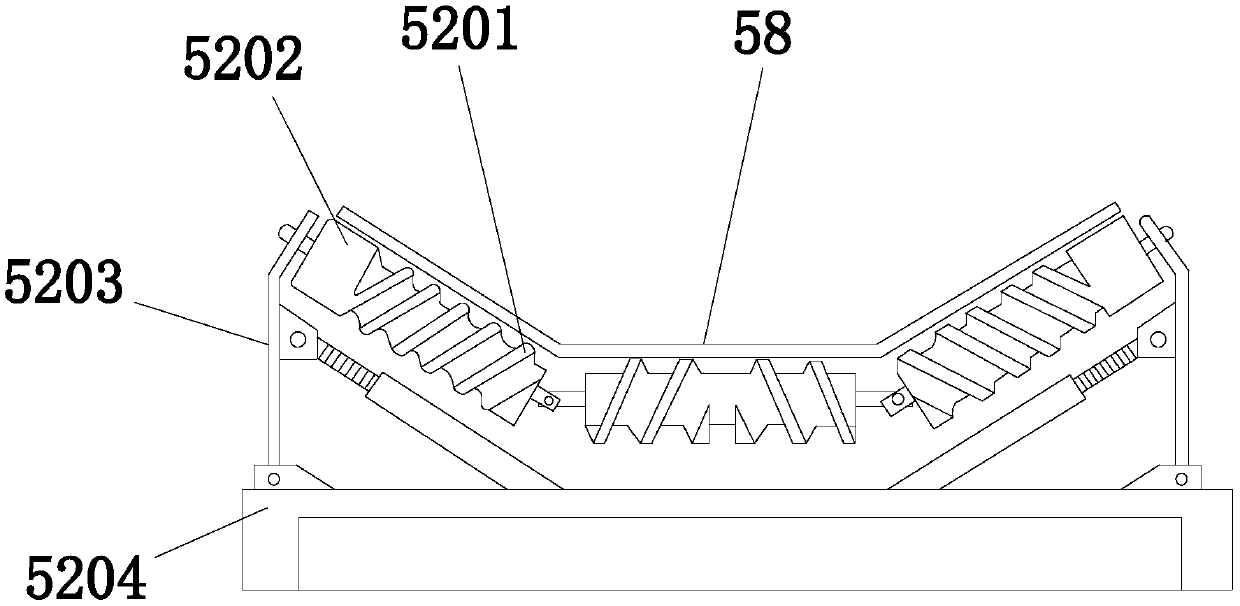

[0027] see Figure 1-Figure 7, the present invention provides a new type of concrete batching machine, its structure includes isolation plate 1, frame 2, adjustable material guide plate 3, storage hopper 4, belt conveyor 5, support frame 6, triangular reinforcement frame 7, mixing weighing bucket 8, belt scale 9; the middle section of the frame 2 is provided with a support frame 6, the support frame 6 is welded to the frame 2, and the left and right sides of the frame 2 are provided with a triangular reinforcement frame 7, and the The reinforcement frame 7 is welded to the frame 2, and two storage hoppers 4 are arranged side by side at equal distances on the frame 2, and the storage hoppers 4 are buckled and fixed on the frame 2, and the top center of the frame 2 is provided with The isolation plate 1, the left and right sides of the isolation plate 1 are welded to the storage hopper 4, the bottom of the storage hopper 4 is provided with a belt conveyor 5, and the belt conveyo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com