Automatic batching machine

A technology of automatic batching and batching barrels, which is applied in the field of machinery, can solve the problems of inability to batch multiple materials, long batching time, and blockage of the outlet, so as to achieve high automation control efficiency, reduce batching time, and improve feeding efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

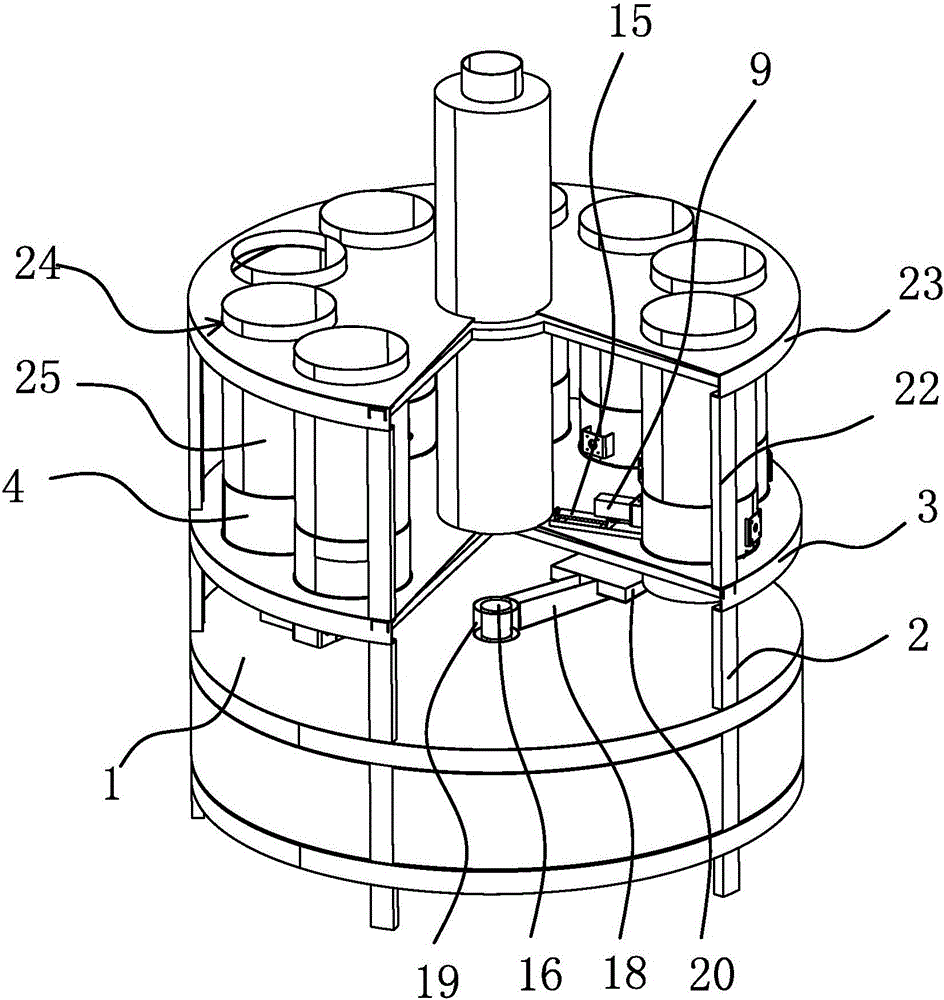

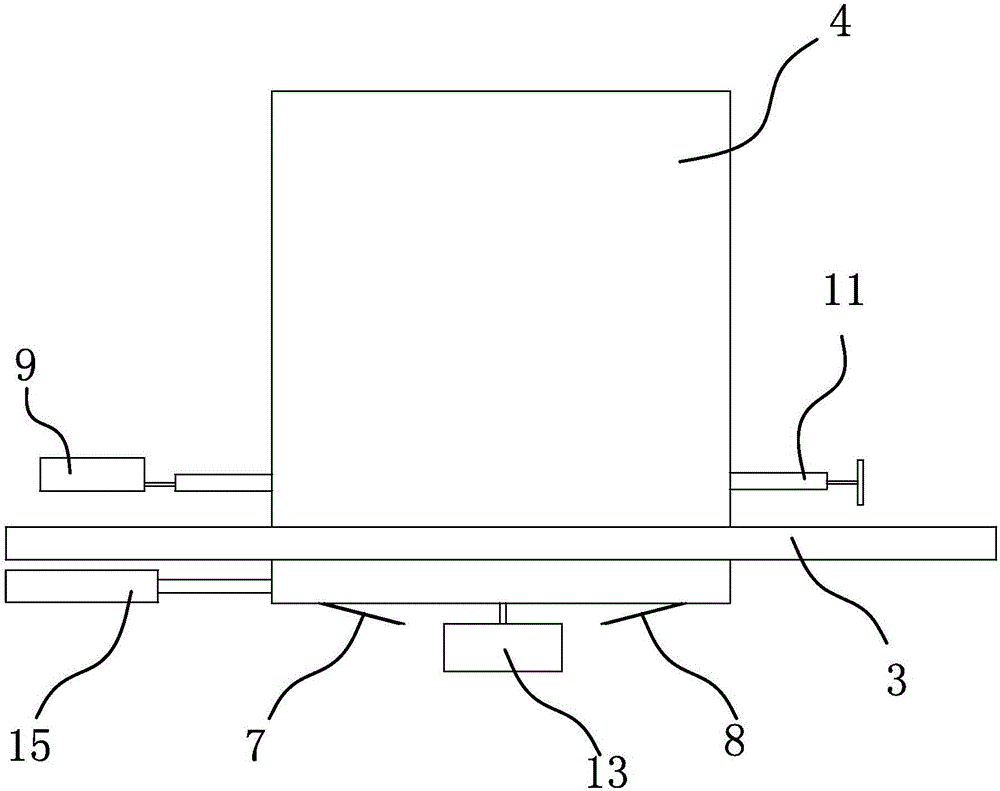

[0030] Such as figure 1 , figure 2 and image 3 Shown, a kind of automatic distributing machine comprises base 1, and a working plate 3 is fixed on the base 1 by some columns one 2, and a mounting plate 23 is fixed on the top of working plate 3 by some columns two 22.

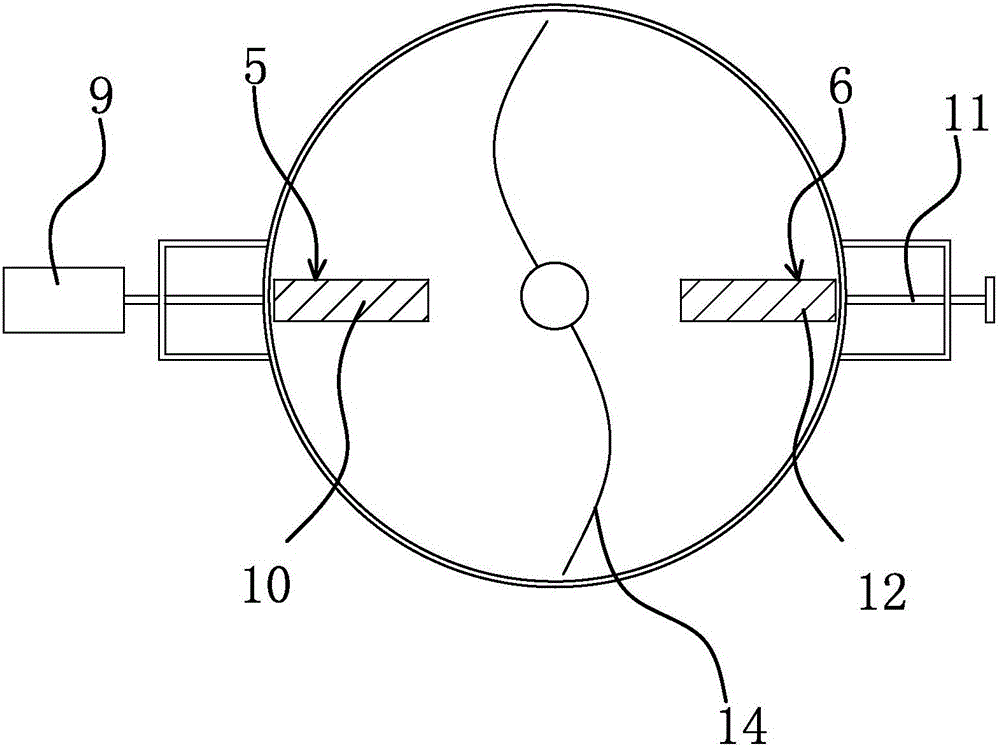

[0031]A blanking space is formed between the base 1 and the working plate 3, and the blanking space is provided with a weighing mechanism capable of weighing various materials. Specifically, the weighing mechanism includes a mounting column 16 arranged on the base 1, and a rotating disk 20 is arranged on the mounting column 16 through a bearing 17. The inner ring of the bearing 17 is fixed to the mounting column 16, and the rotating disk 20 includes a rod body 18, a fixed The sleeve 19 at one end of the rod body 18 and the turntable 20 fixed at the other end of the rod body 18, the sleeve 19 is fixed on the outer ring of the bearing 17, an electronic scale is placed on the turntable 20, and a working plate 3...

Embodiment 2

[0042] The structure and principle of this embodiment are basically the same as the first embodiment, the difference is that in the first embodiment, the rotation positioning structure includes a rotating motor 21 and a controller, the rotating motor 21 is fixed in the mounting column 16, and the rotating motor 21 The output shaft is vertically upwards and the end is fixed with a gear 21a, the outer ring of the bearing 17 is fixed with an internal gear with internal teeth, the gear 21a is meshed with the internal gear, and the rotating motor 21 is connected with the controller; and in this implementation In example two, such as Figure 5 As shown, the rotation positioning structure includes a rotating motor 21 and a controller, the rotating motor 21 is fixed on the lower plate surface of the working plate 3, the output shaft of the rotating motor 21 is vertically fixed with a gear 21a downward, and the outer ring of the bearing 17 is fixed with a The outer ring gear with exter...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com