Concrete distributor with arm support capable of both horizontal rotation and pitching movement

A technology of horizontal rotation and pitching movement, which is applied in the processing of building materials, construction, building construction, etc., which can solve the problem that the boom cannot be at the same time, and achieve the effect of ensuring the quality of pouring

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

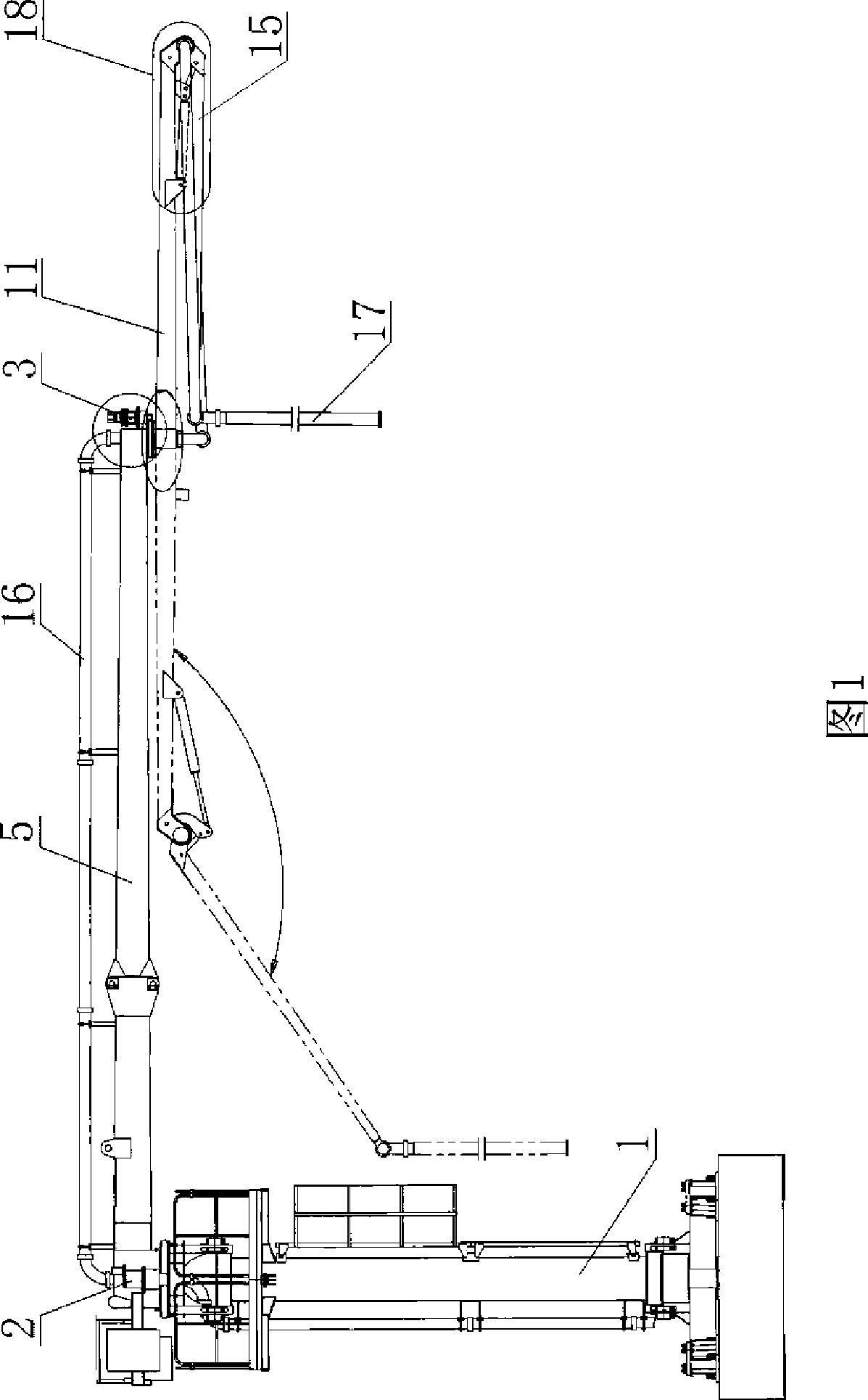

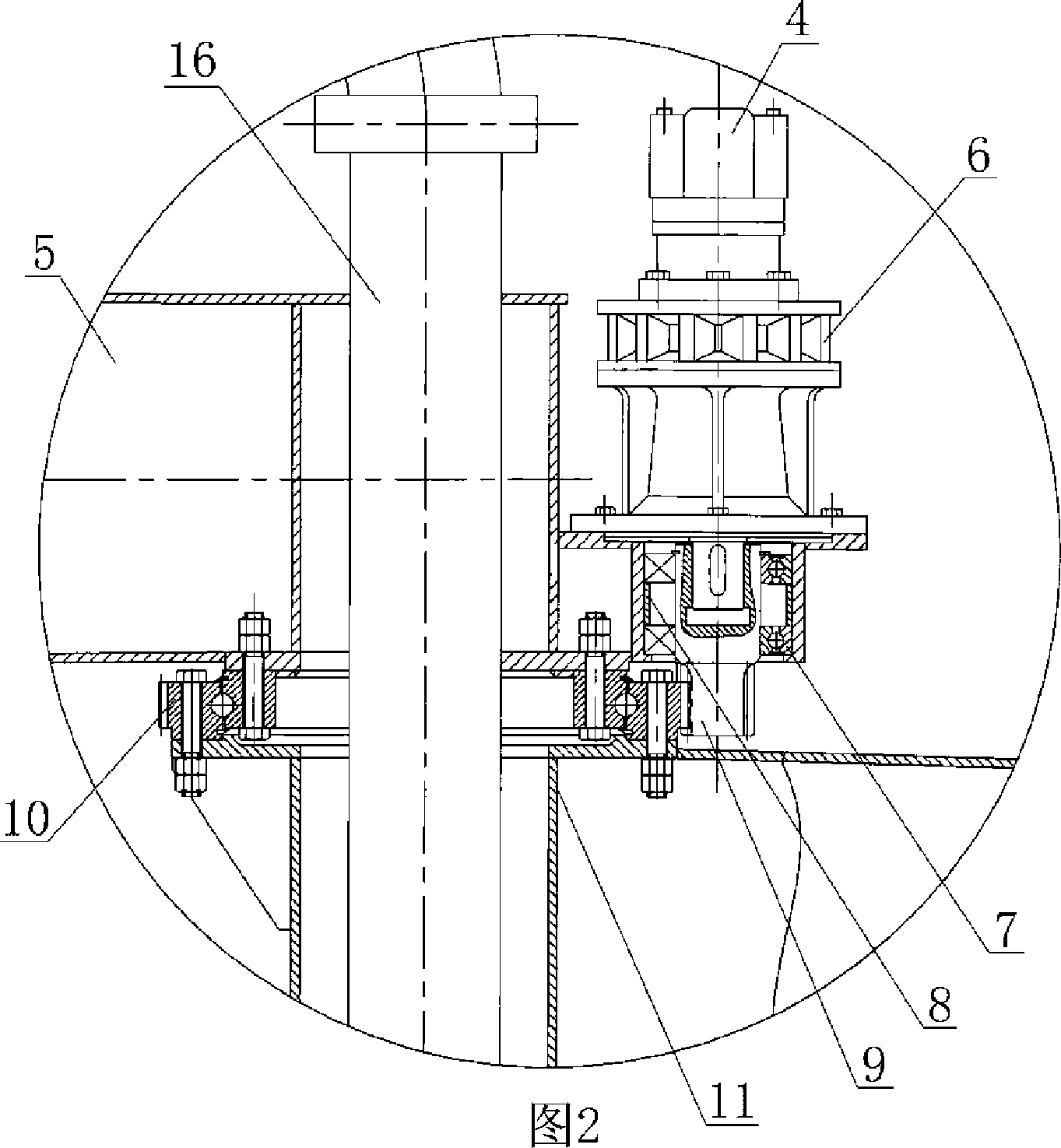

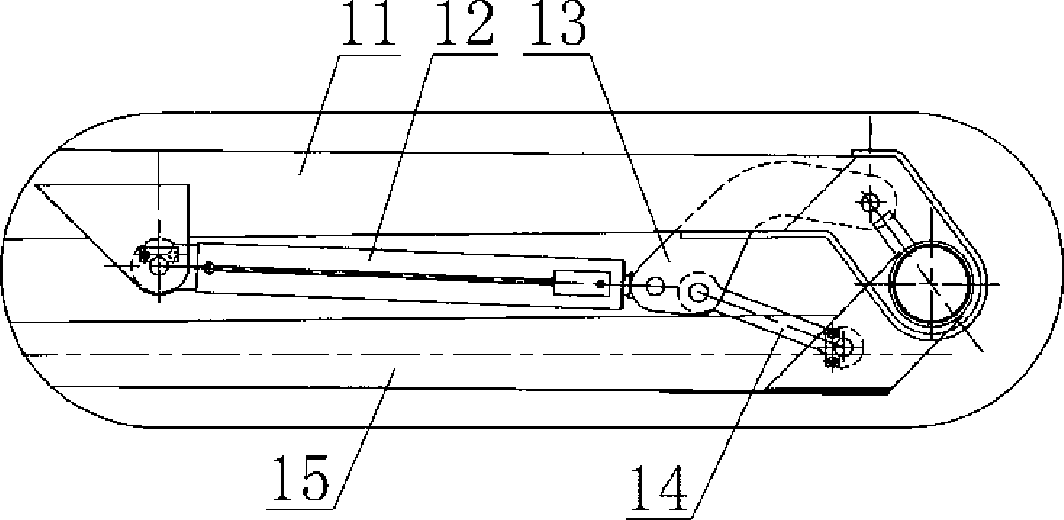

[0018] The embodiment is shown in Fig. 1. This boom horizontal rotation and pitching motion combined boom includes a tower support 1 and a boom system connected in parallel with the concrete pumping pipeline. The head end of the boom system passes through the first The horizontal slewing mechanism 2 is connected with the tower body support 1 by horizontal rotatable rotation. The concrete pumping pipeline is supported by the boom, and its feeding pipe 16 is connected with the discharge nozzle 17 (that is, the rubber hose at the arm end). The above-mentioned boom system is composed of a boom 5. The middle arm 11 and the small arm 15 are connected end-to-end in relative motion. The end of the big arm 5 is connected to the head end of the middle arm 11 through the second horizontal rotation mechanism 3. The end of the middle arm 11 is rotated through the pitch The mechanism 18 is rotatably connected with the head end of the small arm 15 , and the end of the small arm 15 is connecte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com