Piezoelectric ultrasonic device for online monitoring of cement concrete hydration process

A cement concrete, piezoelectric ultrasonic technology, applied in the direction of measuring devices, using sound waves/ultrasonic waves/infrasonic waves to analyze solids, using sound waves/ultrasonic waves/infrasonic waves for material analysis, etc., can solve the damage of cement concrete structures and cannot reflect cement concrete structures Information and hydration degree and other issues, to achieve the effect of changeable structure, strong practicability, and convenient use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

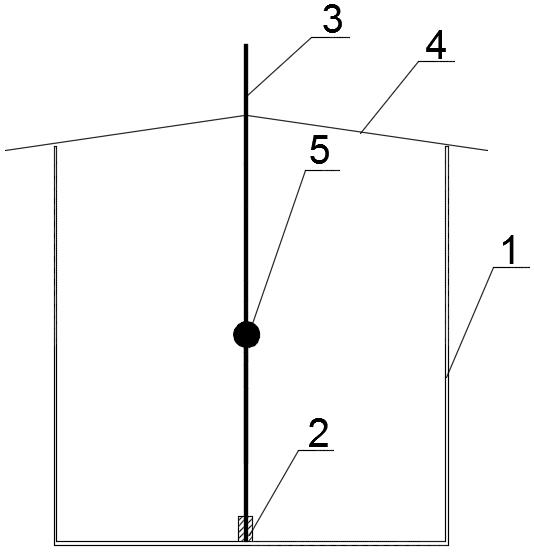

[0039] A piezoelectric ultrasonic device for omnidirectional online monitoring of cement concrete hydration process, the device includes a container 1 for containing cement concrete, a support rod 3 and a spherical piezoelectric ultrasonic sensor 5 . Wherein, there is an opening above the container for containing cement concrete, and a limiting groove 2 is provided on the bottom wall of the container, and the limiting groove is located at the center of the bottom wall of the container. The function of the support rod is to fix the spherical piezoelectric ultrasonic sensor at the center of the container. The support rod exists independently and can be put into the container when in use. The upper part of the support rod is provided with a bracket, and the bottom of the support rod is located in the limit groove Inside, the support rod is erected in the container through the limit slot and the bracket, the spherical piezoelectric ultrasonic sensor is fixed on the support rod, the...

Embodiment 2

[0048] A piezoelectric ultrasonic device for on-line monitoring of cement concrete hydration process, the device includes a container 1 for containing cement concrete, a support rod 3 and a spherical piezoelectric ultrasonic sensor 5. Wherein, there is an opening above the container for containing cement concrete, and a limiting groove 2 is provided on the bottom wall of the container, and the limiting groove is located at the center of the bottom wall of the container. The function of the support rod is to fix the spherical piezoelectric ultrasonic sensor at the center of the container. The support rod exists independently and can be put into the container when in use. The upper part of the support rod is provided with a bracket, and the bottom of the support rod is located in the limit groove Inside, the support rod is erected in the container through the limit slot and the bracket, the spherical piezoelectric ultrasonic sensor is fixed on the support rod, the support rod run...

Embodiment 3

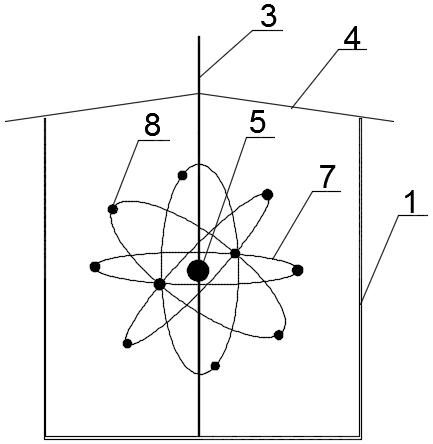

[0054] Such as image 3As shown, a piezoelectric ultrasonic device for omnidirectional online monitoring of cement concrete hydration process, the device includes a container 1 for containing cement concrete, a support rod 3 and a spherical piezoelectric ultrasonic sensor 5 . Wherein, there is an opening above the container for containing cement concrete, and a limiting groove is provided on the bottom wall of the container, and the limiting groove is located at the center of the bottom wall of the container. The function of the support rod is to fix the spherical piezoelectric ultrasonic sensor at the center of the container. The support rod exists independently and can be put into the container when in use. The upper part of the support rod is provided with a bracket, and the bottom of the support rod is located in the limit groove Inside, the support rod is erected in the container through the limit slot and the bracket, the spherical piezoelectric ultrasonic sensor is fixe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com