Steel fiber concrete with high fracture resistance and preparation method thereof

A technology of steel fiber concrete and high flexural resistance, applied in the field of concrete, can solve the problems of not meeting the performance index requirements of high flexural steel fiber concrete, and achieve the effect of reducing the thickness of the road surface, reducing the cost of the project, and good construction workability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

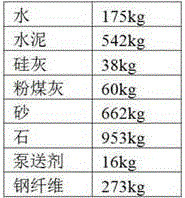

[0037] Embodiment 1; A kind of high flexural steel fiber concrete, raw material composition and weight are as follows:

[0038]

[0039] The preparation method of high flexural steel fiber reinforced concrete comprises the following steps:

[0040] (1) Weighing: Weigh the raw materials according to the mix ratio;

[0041] (2) Stirring: first add stones and sand and stir for 15s, then add steel fiber and continue stirring for 20s, then add silica fume and fly ash and stir for 25s, finally add admixture and water, and continue stirring for 35s to form steel fiber concrete.

[0042] (3) Pouring molding: under the action of the plate vibrator, the construction and molding of the steel fiber concrete mixture is completed. At the same time, complete the 400mm×100mm×100mm flexural test block, standardize for 28 days, take out the test block, and test the flexural strength.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com