Concrete mixer unit

A concrete and mixing technology, which is used in batching storage, batching weighing instruments, clay preparation devices, etc., can solve problems such as uneven thickness of raw materials, splashing of materials, and failure of material distribution, saving mixing time and processing. Efficiency improvement, wide range of use effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

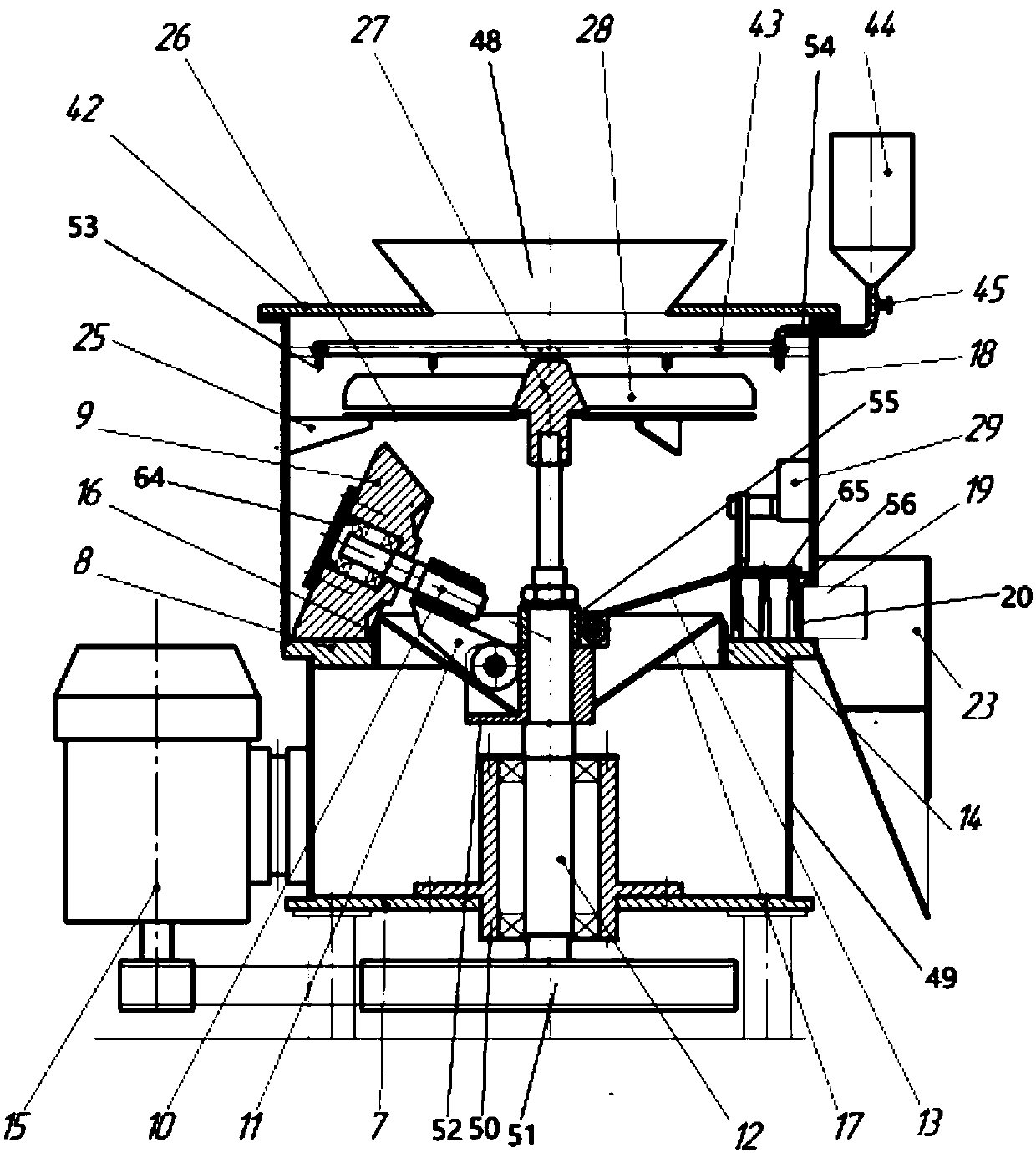

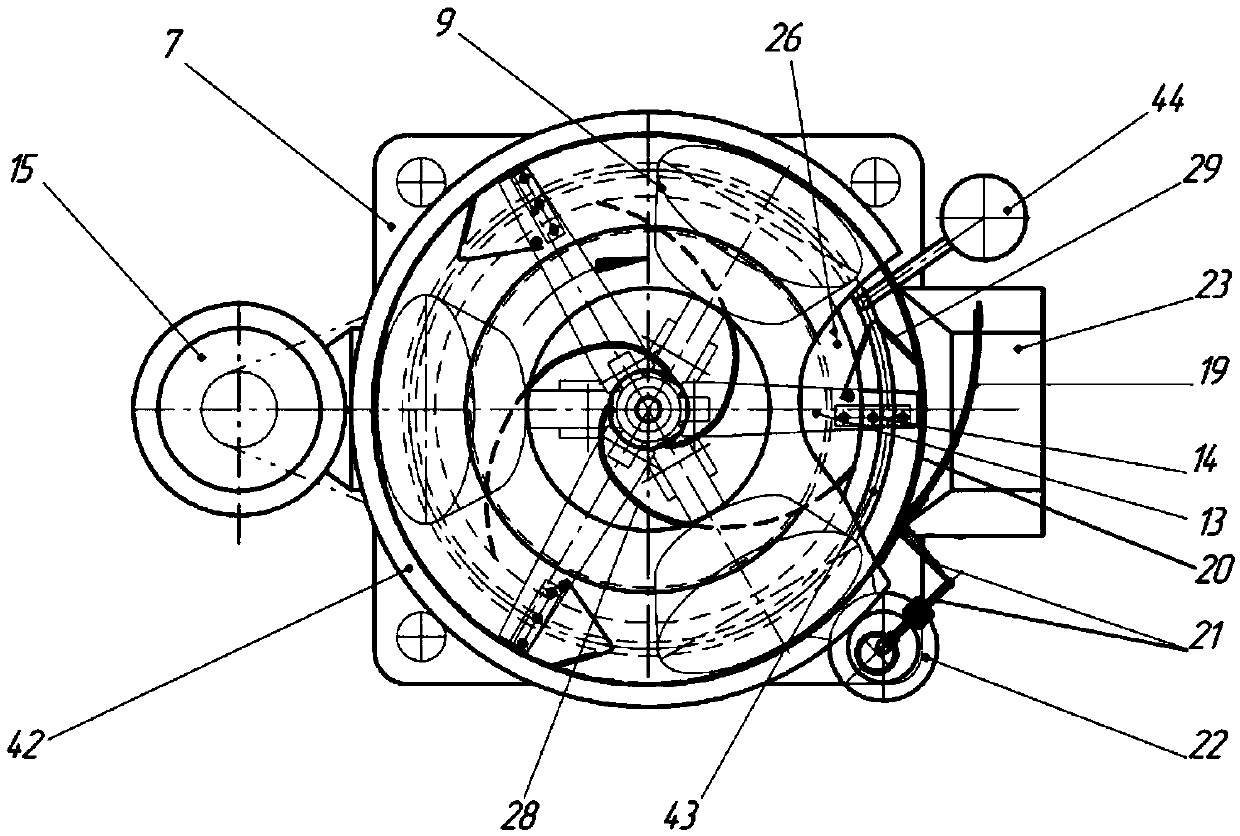

[0015] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

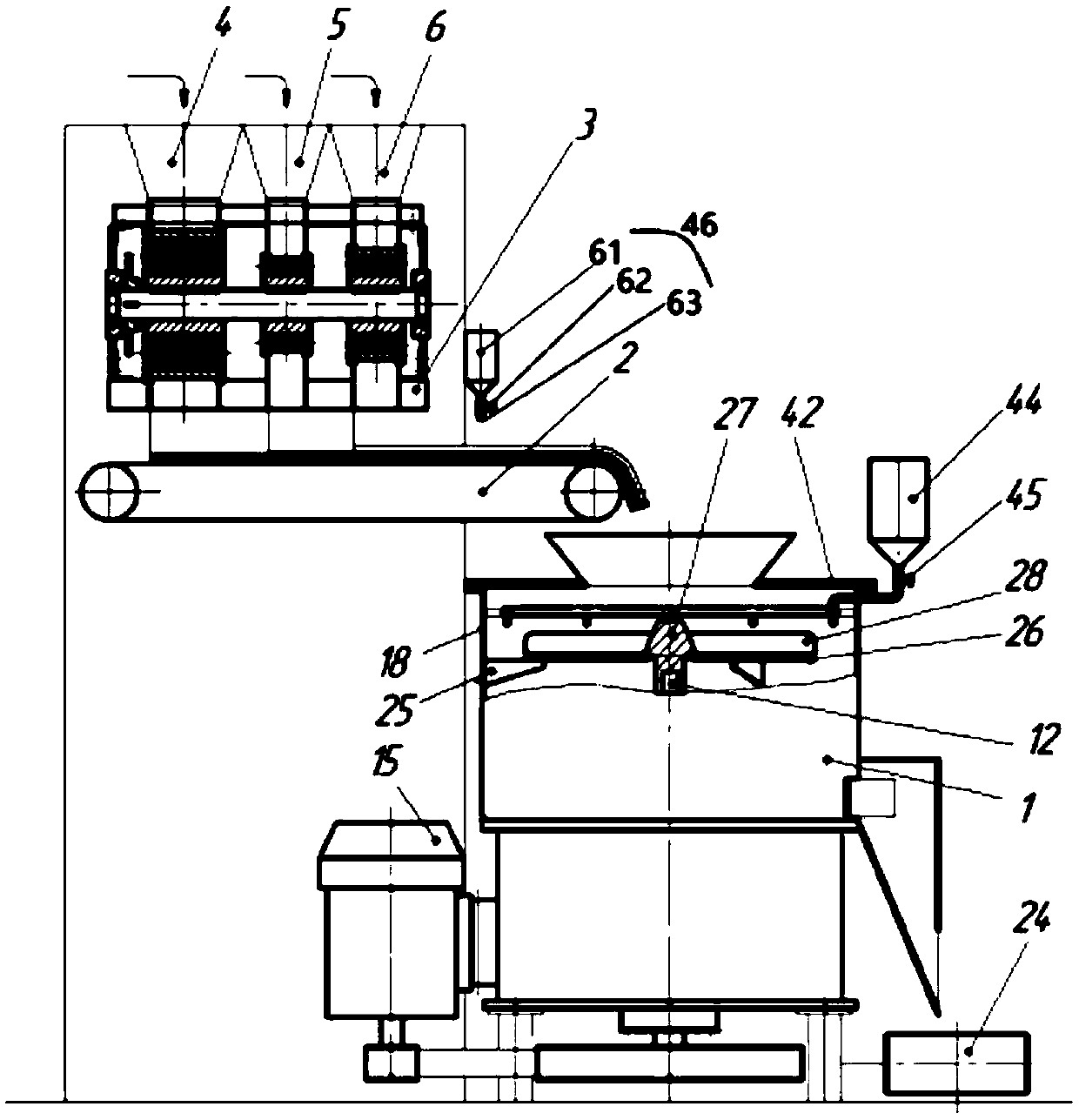

[0016] As shown in the figure, a concrete mixing unit is characterized in that it includes a raw material mixing processor 1, a belt feeder 2, a grid feeder 3, a hopper I4, a hopper II5, a hopper III6, and a conveyor belt I24; the hopper I4, hopper II5, and hopper III6 are respectively used to store various concrete raw materials; the partition feeder 3 is located above the belt feeder 2 and below the hopper I4, hopper II5, and hopper III6; the partition feeder 3 Parallel to the conveyor shaft 47 of the belt feeder 2; the raw material mixing processor 1 is located below the belt feeder 2; the feed inlet of the raw material mixing processor 1 is connected to the belt feeder The discharge port 48; the conveyor belt I24 is located below the side of the raw material mixing processor 1 for receiving and delivering the processed raw materials.

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com