Polyurethane microcapsule dispersing agent preparation method and product thereof

A technology of polyurethane microcapsules and dispersions, which is applied to the preparation of microcapsule preparations and microspheres, can solve the problems of storage stability, centrifugal stability, dilution stability, poor acid and alkali resistance, etc., and achieve enhanced storage stability, excellent Storage stability, wide market value effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0044] First aspect, provide a kind of preparation method of polyurethane microcapsule dispersion liquid, comprise the following steps:

[0045] S1: React excess polyisocyanate with hydroxyl-containing hydrophilic surfactant at 65-90°C for 2-4 hours under the catalysis of tetramethylethylenediamine to form polyurethane prepolymer;

[0046] S2: Reduce the temperature of the polyurethane prepolymer generated in S1 to 25-40°C, and stir and mix with the core material evenly to form an oil phase; add the oil phase to an aqueous polyvinyl alcohol solution, and homogeneously emulsify it to prepare Obtain O / W type emulsion;

[0047] S3: At 40-60°C, slowly add a polyamine aqueous solution to the O / W emulsion prepared in S2, after the dripping is completed, heat and cure for 1-2 hours, the wall material is completely formed, and the polyurethane is obtained microcapsule dispersion.

[0048] In a preferred embodiment, the hydroxylated hydrophilic surfactant is a polyhydroxy nonionic su...

Embodiment 1

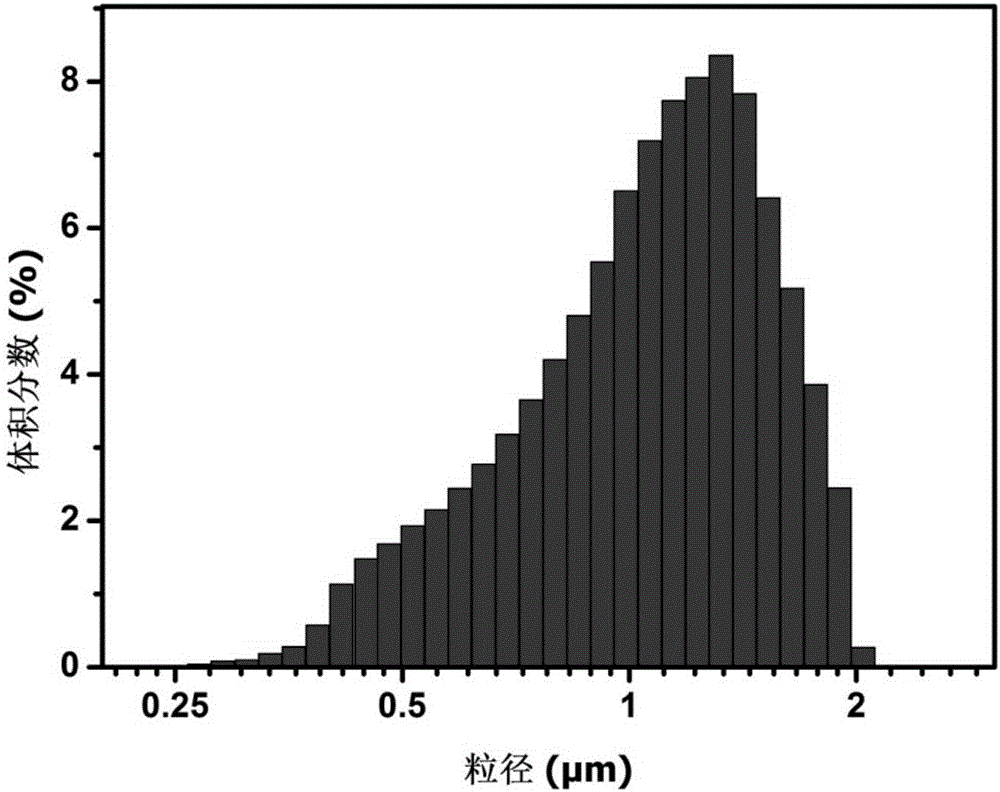

[0084] Add 10.2g isophorone diisocyanate IPDI (Bayer, MaterialScience), 4.0g castor oil polyoxyethylene ether EL-40 (Jiangsu Haian Petrochemical Factory), 0.1g tetramethylethylenediamine (Sinopharm Reagent) to four In the bottle, after stirring at 80°C for 2.5h at a rotating speed of 800rpm, a polyurethane prepolymer was generated; the temperature of the polyurethane prepolymer was reduced to 35°C, and it was mixed with 70.0g 32# paraffin (Joule Wax Industry), 5.0g butyl acetate (National Medicine Reagent) is stirred and mixed uniformly to form an oil phase; then this oil phase is added to 199.0g of PVA (Sichuan Chuanwei Chemical) aqueous solution (wherein, the mass concentration of PVA in the whole dispersion system is 3.0 wt%), after stirring evenly, use a high-speed shearing disperser to homogenize for 5min with a rotating speed of 13000rpm, so that the oil phase is dispersed in the water phase, and an O / W type emulsion is obtained; the O / W type emulsion is transferred to fo...

Embodiment 2

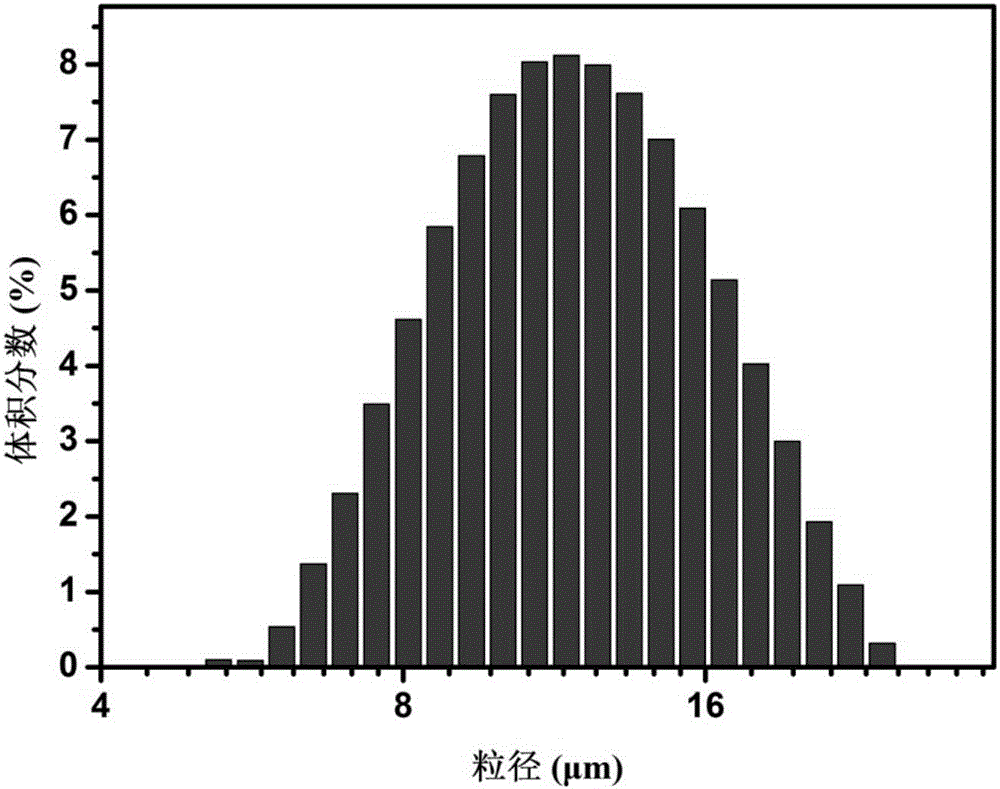

[0087] 10.2g isophorone diisocyanate IPDI (Bayer, MaterialScience), 5.0g polyoxyethylene-polyoxypropylene copolymer Pluronic L64 (BASF), 0.1g tetramethylethylenediamine (Sinopharm Reagent) were added to the four ports In the bottle, after stirring for 3 hours at 75°C with a rotating speed of 800rpm, a polyurethane prepolymer was generated; the temperature of the polyurethane prepolymer was reduced to 25°C, and it was mixed with 8.0g of disperse dye Artelon Red SW-2B (Shanghai Yayun Textile Chemical Industry), 12.0g butyl acetate (Chinese Medicine Reagent) are stirred and mixed evenly to form an oil phase; then the oil phase is added to 253.0g of PVA (Sichuan Chuanwei Chemical) aqueous solution (wherein, PVA is in the whole dispersion system The mass concentration in the mixture is 2.5wt%), after stirring evenly, use a high-speed shear disperser to homogenize for 5min with a rotating speed of 8000rpm, so that the oil phase is dispersed in the water phase, and an O / W type emulsio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com