Coloring combination, color filter and color liquid crystal display element

A coloring composition and coloring agent technology, applied in the direction of instruments, optical filters, optics, etc., can solve the problems of difficulty in achieving high contrast, poor storage stability of coloring compositions, and inability to obtain sufficient contrast ratio, etc., to achieve high preservation The effect of stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0237] Below, an Example is given and the embodiment of this invention is demonstrated more concretely. However, the present invention is not limited by the following examples.

[0238] Analysis of Dispersants

[0239] Dispersant B1

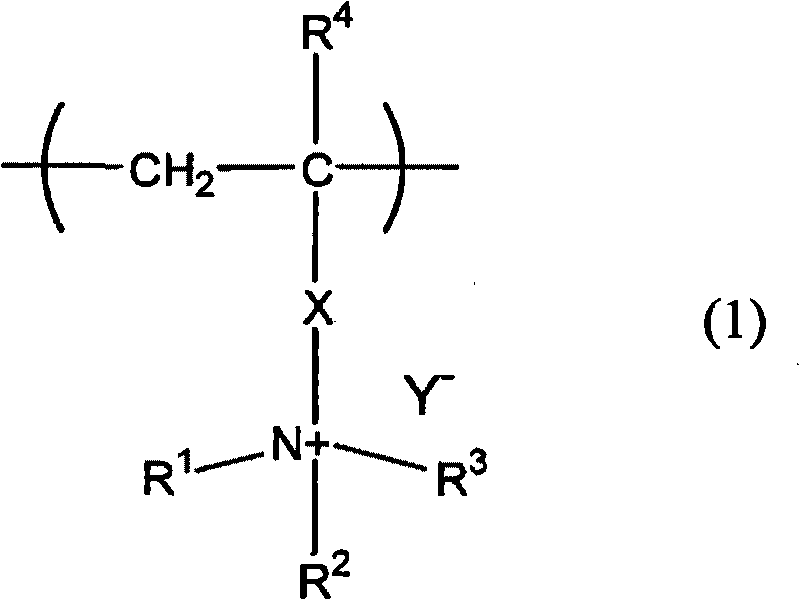

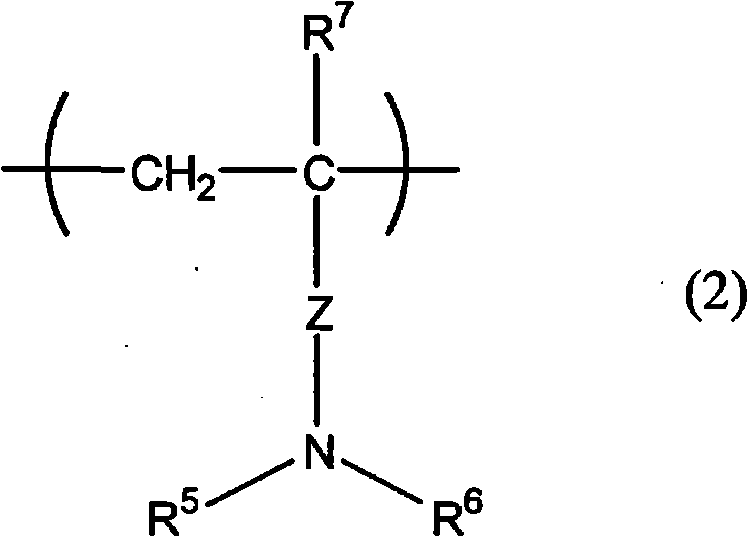

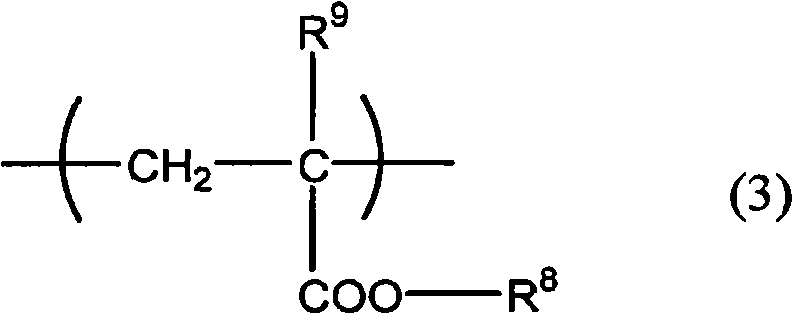

[0240] Dispersant B1 is a commercially available pigment wetting and dispersing agent, and is a solution of propylene glycol methyl ether acetate / butyl cellosolve=1 / 1 (mass ratio) of a modified acrylic block copolymer (solid content concentration: 40 mass % , acid value = 0). Through thermal decomposition GC-MS, FT-IR measurement, and proton NMR, it was confirmed that dispersant B 1 was composed of The A block of the repeating unit, and the methacrylic acid with A block copolymer of B blocks of repeating units of esters (A / B=38 / 62). Mw=2700. The copolymerization ratio of each repeating unit is methacryloxyethylbenzyldimethylammonium chloride / dimethylaminoethyl methacrylate / methyl methacrylate / butyl methacrylate / methacrylic acid 2 -Ethylh...

preparation example 1

[0254] 15 parts by mass of C.I. Pigment Red 254 (manufactured by Chiba Special Chemicals Co., Ltd., trade name BK-CF) as (A) colorant, and 3 parts by mass (in terms of solid content) of a specific dispersant as (B) dispersant That is, dispersant B1, propylene glycol monomethyl ether acetate / propylene glycol monoethyl ether=90 / 10 (mass ratio) mixed solvent as a solvent, wherein the mixed solvent is used in an amount so that the solid content concentration is 20% by mass, The colorant dispersion liquid (M-1) was prepared by mixing and dispersing with a bead mill for 12 hours.

preparation example 2~13

[0256] Colorant dispersion liquids (M-2) to (M-15) were prepared in the same manner as in Preparation Example 1 except that the colorant and dispersant were changed as shown in Table 1 in Preparation Example 1.

[0257]

[0258] In Table 1, "R254" refers to C.I. Pigment Red 254, "R177" refers to C.I. Pigment Red 177, "Y150" refers to C.I. Pigment Yellow 150, "Y139" refers to C.I. Pigment Yellow 139, "G36 ” refers to C.I. Pigment Green 36, “B15:6” refers to C.I. Pigment Blue 15:6, and “V23” refers to C.I. Pigment Violet 23.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com