Emulsion carbon fiber sizing agent as well as preparation method and application of sizing agent

An emulsion-type carbon fiber and carbon fiber technology, which is applied in fiber processing, textiles and papermaking, etc., to achieve the effects of enhancing storage stability and use stability, enhancing interlayer shear strength, and improving storage stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] An emulsion type carbon fiber sizing agent is prepared by the following steps:

[0040] Mix 2 g of bisphenol A epoxy resin, 97 g of deionized water, and 0.9 g of surfactant (0.45 g Nippon Emulsifier / Nikon 707-SF, 0.45 g Nippon Emulsifier / Nikon 723-SF) Mix, stir at 40°C at a speed of 1000r / min for 90min; then high-speed shear emulsification at a speed of 10000r / min at 40°C for 30min; finally add 0.1g of ammonium chloride to the mixed solution after high-speed shear emulsification , stirred at 1000r / min for 20min at 40°C to obtain an emulsion carbon fiber sizing agent.

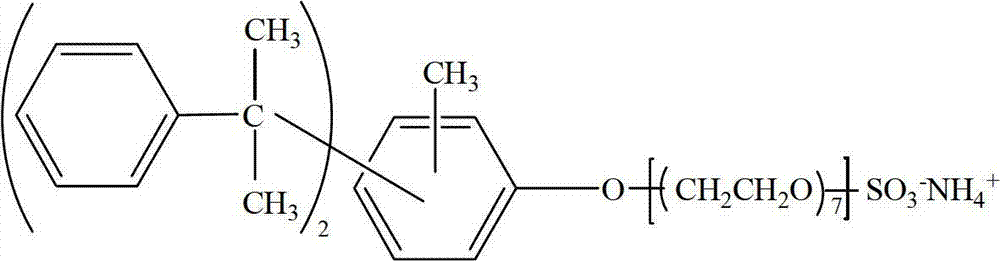

[0041] The structure of a surfactant is shown below:

[0042]

[0043] Nippon Emulsifier Company / Nikon 707-SF

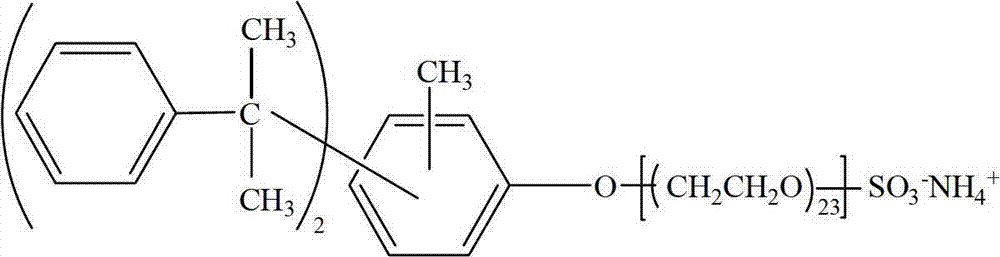

[0044]

[0045] Nippon Emulsifier Company / Nikon 723-SF

Embodiment 2

[0047] An emulsion type carbon fiber sizing agent is prepared by the following steps:

[0048] Mix 5g of bisphenol F type epoxy resin, 94.3g of deionized water and 0.5g of surfactant (0.25g Mitsubishi Rayon Company / BPEO20SON, 0.25g Mitsubishi Rayon Company / SPEO120SON) at 60°C in Stir at a speed of 750r / min for 70min; then high-speed shear emulsification at a speed of 7500r / min at 60°C for 20min; finally add 0.2g of ammonium chloride to the mixed solution after high-speed shear emulsification, Stir for 15 minutes at a speed of 1 / min to obtain an emulsion-type carbon fiber sizing agent.

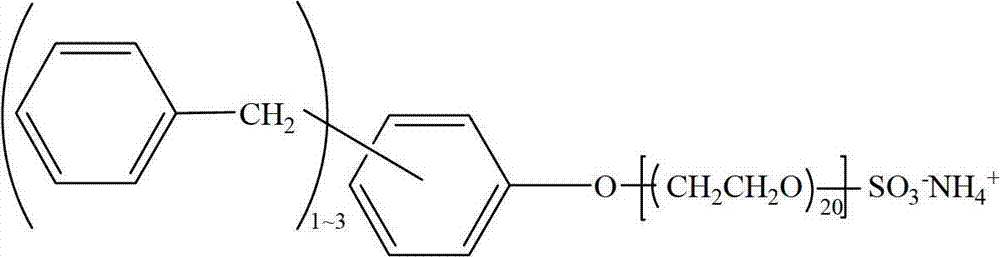

[0049] The structure of a surfactant is shown below:

[0050]

[0051] Mitsubishi Rayon Corporation / BPEO20SON

[0052]

[0053] Mitsubishi Rayon Corporation / SPEO120SON

Embodiment 3

[0055] An emulsion type carbon fiber sizing agent is prepared by the following steps:

[0056]Mix 10g of novolac epoxy resin, 86g of deionized water and 3.5g of surfactants (2.0g of polyoxyethylene alkyl ether, 1.5g of polyoxyethylene alkyl phenyl ether) at 60°C at 500r / min Stir for 50 minutes at a rotating speed of 5000r / min; then high-speed shear emulsification at a speed of 5000r / min at 60°C for 10 minutes; finally add 0.5g of ammonium chloride to the mixed solution after high-speed shear emulsification, and Stir at a rotating speed for 10 minutes to obtain an emulsion carbon fiber sizing agent.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com