Multi-crosslinking high-elastic outer-wall emulsion as well as preparation method and application thereof

A multi-crosslinking, high-elasticity technology used in biocide-containing paints, antifouling/underwater coatings, coatings, etc. Balance and other issues to achieve the effect of improving crosslinking density, improving storage stability, improving tensile strength and elongation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0041] In any embodiment, the preparation method at least includes the following steps:

[0042] Step 1. Weigh each component according to the aforementioned raw material ratio;

[0043] Step 2. Use deionized water to dissolve the emulsifier to obtain an emulsifier solution;

[0044] Step 3. Mix the polymerization stabilizer, the hydrophilic monomer, the carboxyl crosslinking monomer and the main monomer, and add them to the emulsifier solution under stirring conditions for dispersion to obtain a dispersion;

[0045] Step 4. Add water and pH buffer to the reactor, and under stirring conditions, the temperature is raised to 80-84°C, and 8-12wt% of the dispersion liquid and 30-35wt% of the initiator are added to the reactor , The reaction is carried out to obtain the seed liquid;

[0046] Step 5. Dissolve the remaining initiator, and then add the remaining initiator and the remaining dispersion liquid dropwise to the seed liquid. During the dropping process, add the silane coupling agent...

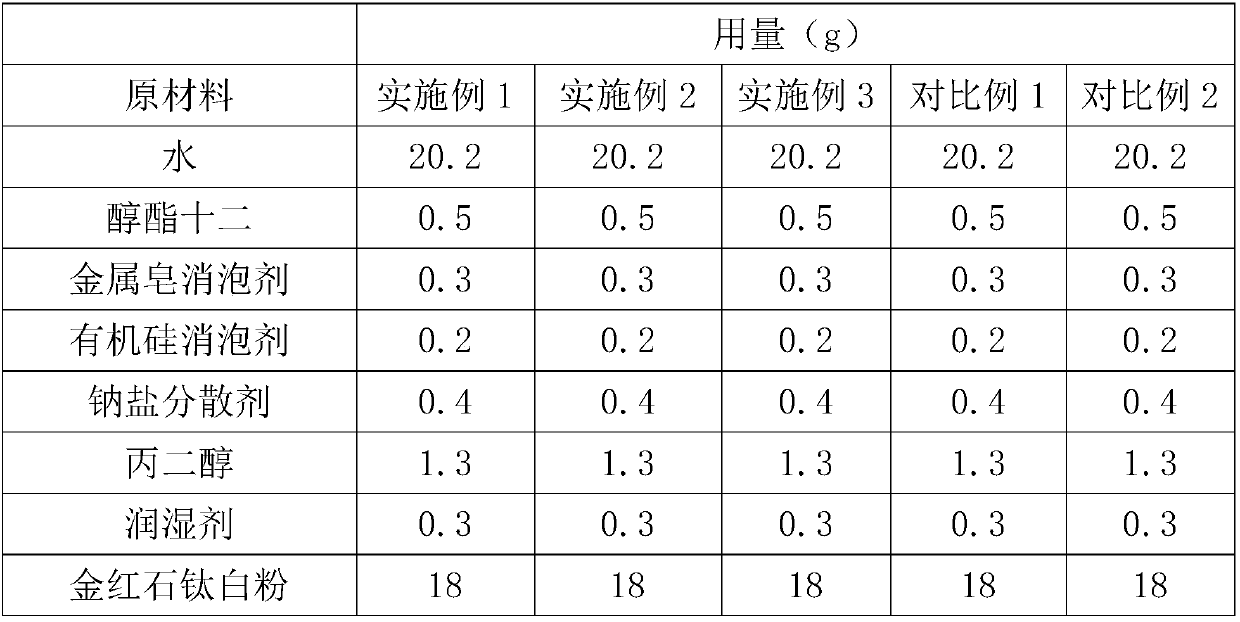

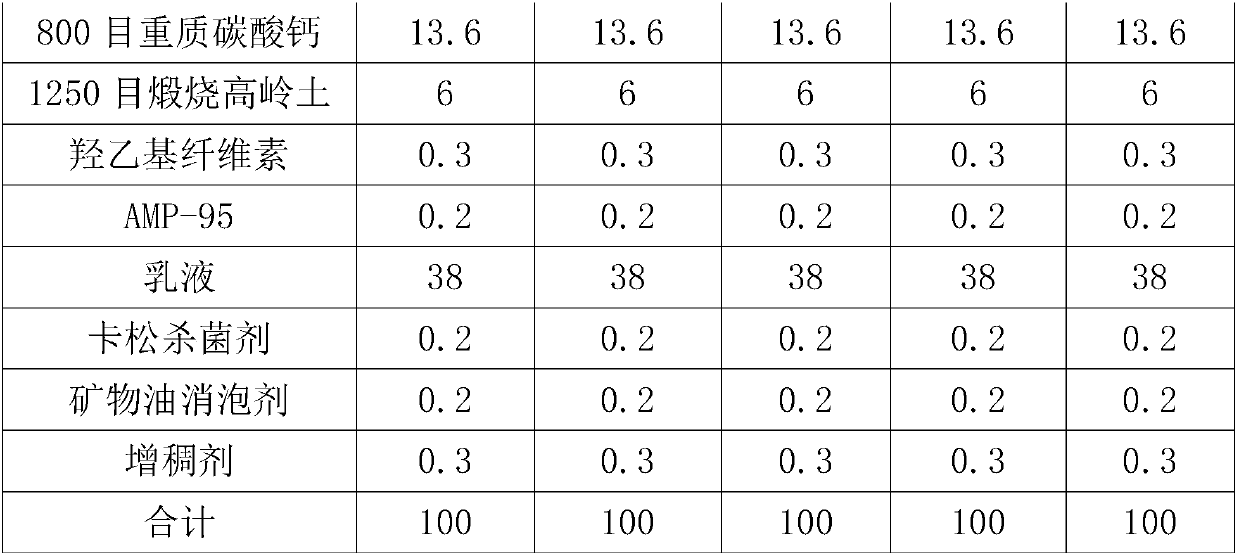

Embodiment 1

[0056] This embodiment provides a multiple cross-linked high-elastic exterior wall emulsion. The content of each component of the emulsion is calculated in parts by weight as shown in Table 1 below.

Embodiment 2

[0058] This embodiment provides a multiple cross-linked high-elastic exterior wall emulsion. The content of each component of the emulsion is calculated in parts by weight as shown in Table 1 below.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com