Method for producing conductive material

A technology of conductive material and manufacturing method, applied in the direction of printed circuit manufacturing, cable/conductor manufacturing, conductive layer on insulating carrier, etc., to achieve the effects of high storage stability, high transparency and conductivity, and high conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0255] An example of the first aspect of the present invention is shown below. In order to produce the conductive material precursor, as a transparent support, a polyethylene terephthalate film having a layer containing polyvinylidene chloride with a thickness of 100 μm was used. Before coating the physical development core layer, the dry mass of gelatin coated on the film is 50mg / m 2 The base layer is dried. Next, as described below, a physical development core layer coating solution containing palladium sulfide was prepared.

[0256]

[0257] A solution palladium chloride 5g

[0258] Hydrochloric acid 40ml

[0259] Distilled water 1000ml

[0260] Solution B Sodium sulfide (soda) 8.6g

[0261] Distilled water 1000ml

[0262] The A liquid and the B liquid were mixed while stirring, and passed through a column filled with an ion exchange resin after 30 minutes to obtain a palladium chloride sol.

[0263]

[0264] The palladium chloride sol 50ml

[0265] 2% by mass glutar...

Embodiment 2

[0310] The test was performed in the same manner as in Example 1 except that the post-treatment liquids 1-9 of Example 1 were used, and the treatment temperature and treatment time were changed. As a result, the results shown in Table 3 were obtained.

[0311] table 3

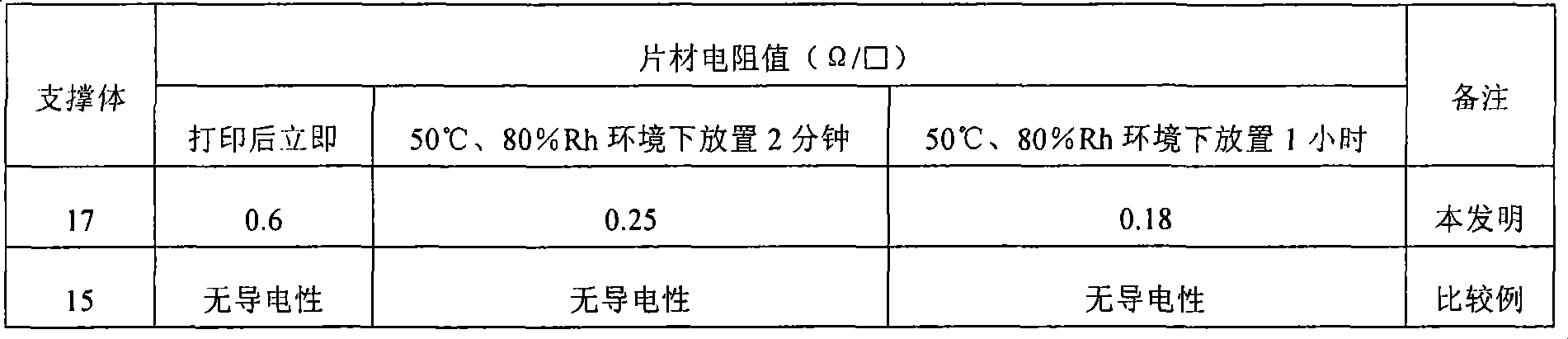

[0312] Conductive material

[0313] From Table 3, it can be fully understood that the surprising effect of the present invention that the resistance value can be reduced to 1 / 5 of the original value by the post-treatment at 60°C for only 10 seconds.

Embodiment 3

[0315] In the same manner as in Example 1, a back coat was applied to the polyethylene terephthalate film.

[0316] Next, the silver halide emulsion layer 2 was coated on the surface of the support on the opposite side to the surface on which the back coat was provided. The silver halide emulsion is produced by the usual double injection mixing method of the silver halide emulsion for photographs. The silver halide emulsion is formulated into 40 mol% silver chloride and 60 mol% silver bromide, with an average particle size of 0.15 μm. According to the fixing method, the silver halide emulsion obtained in this way was subjected to gold sulfur sensitization using sodium thiosulfate and chloroauric acid. The silver halide emulsion obtained in this way contains 1 g of gelatin per 3 g of silver.

[0317] 2 >

[0318] Gelatin 1g

[0319] Silver halide emulsion equivalent to 3.0g silver

[0320] l—Phenyl—5-mercaptotetrazole 3.0g

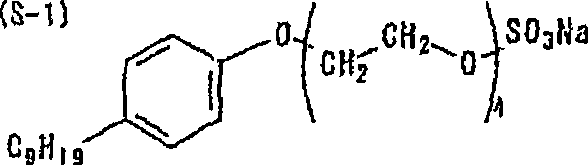

[0321] Surfactant (S-1) 20mg

[0322] Glyoxal (40% by mas...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

| Surface resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com