Silicone caulking material for concrete expansion joints of ballastless tracks and preparation method thereof

A ballastless track and caulking material technology, applied in the direction of chemical instruments and methods, other chemical processes, adhesive additives, etc., can solve the problems of poor deep curing performance of caulking materials, non-curing performance of materials, and easy "wrinkling" on the surface , to achieve the effect of improving deep curing performance, improving storage stability, and reducing surface "wrinkles"

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

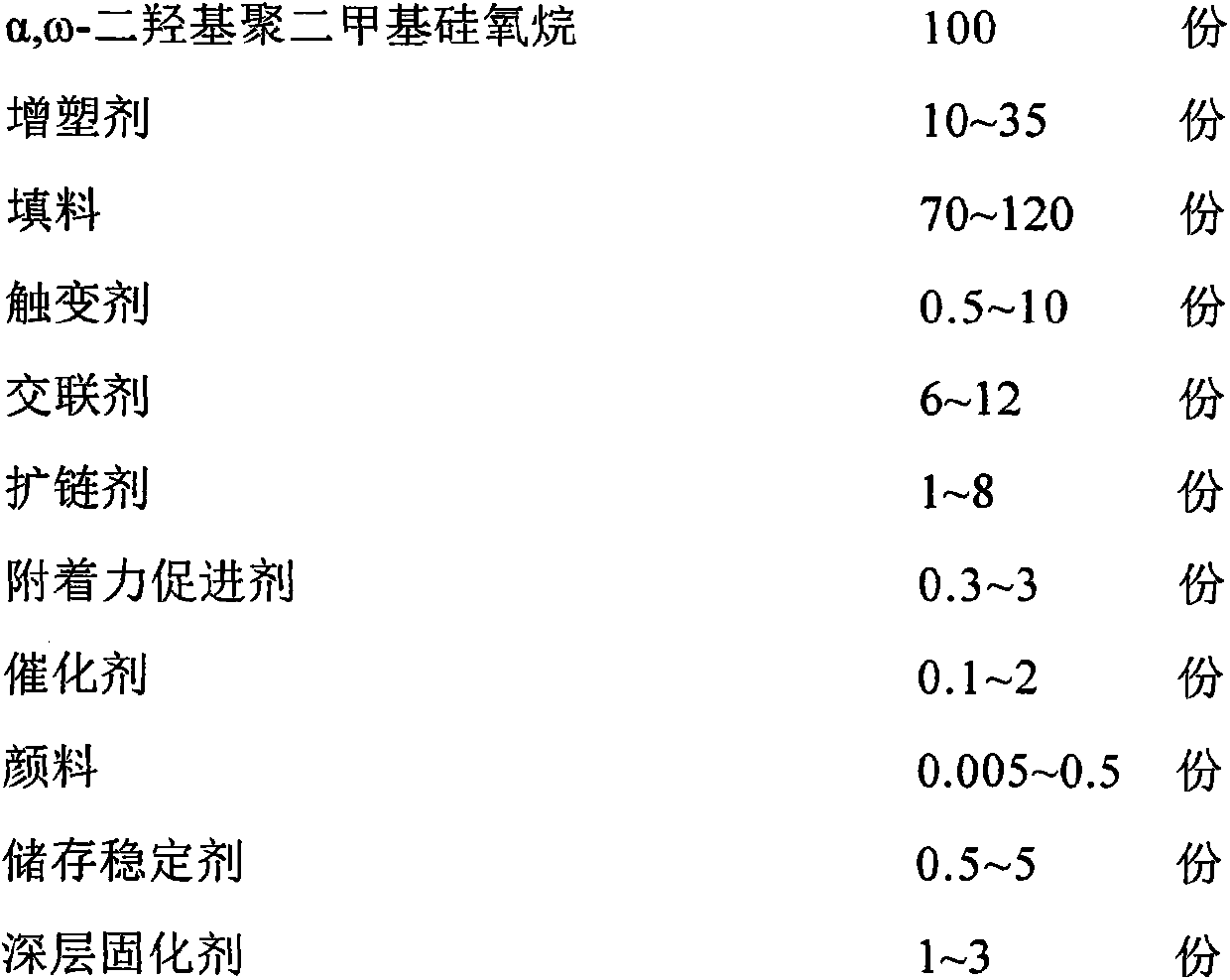

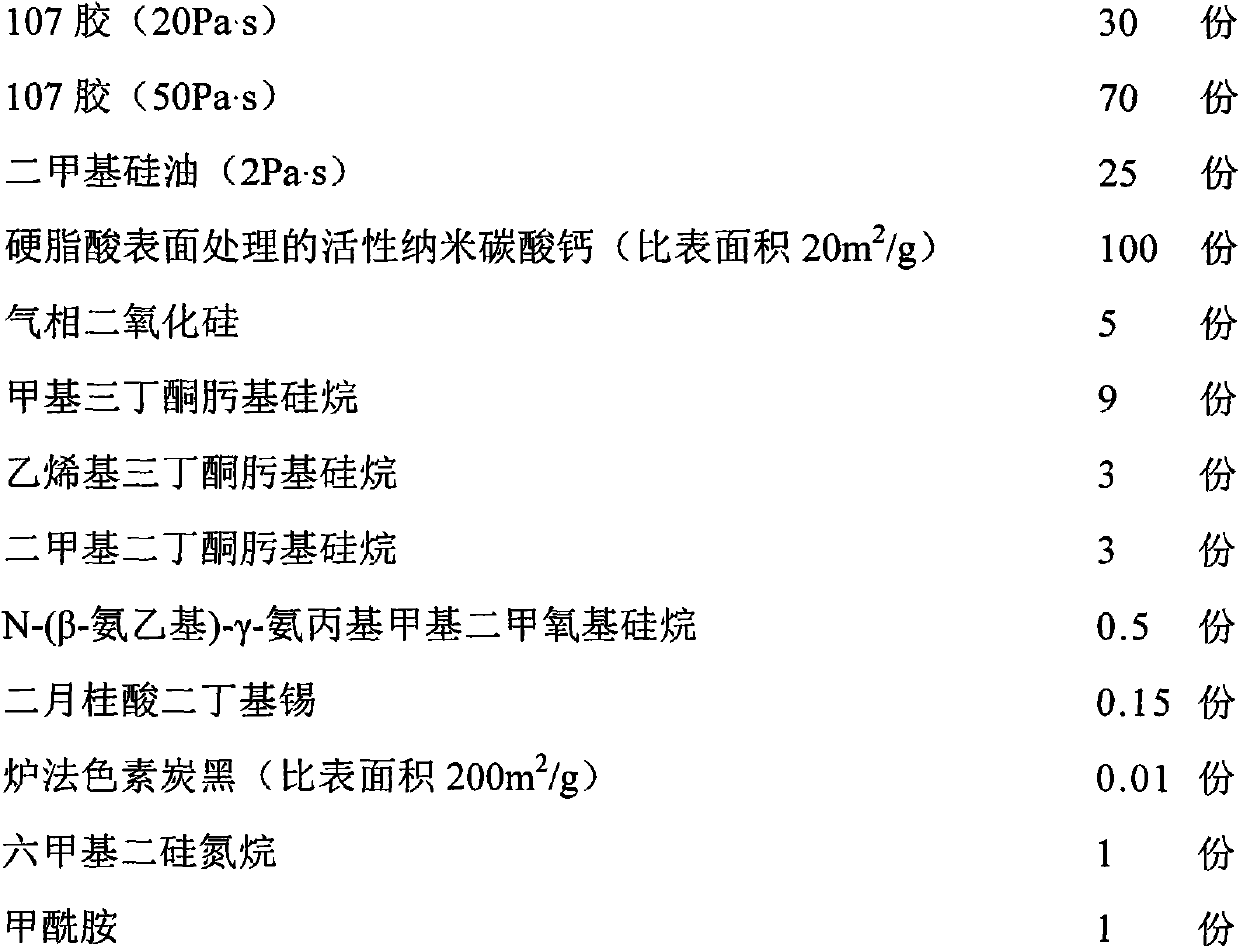

[0034] Material composition:

[0035]

[0036] Preparation:

[0037] The above table shows the composition of raw materials in Example 1. Mix hexamethyldisilazane and plasticizer at a ratio of 1:1 by mass and stir evenly, stir at 110°C for 3 hours, cool and seal for later use; Add polydimethylsiloxane, plasticizer, filler, thixotropic agent and pigment to the vacuum kneader in sequence, and dehydrate under vacuum at 130°C for 3 hours at a speed of 30rpm to obtain the base rubber; put the base rubber into three-roll grinding Grind on the machine to a fineness of 45 μm, and cool to room temperature; put the ground rubber base into a power mixer, use a planetary paddle at 60 rpm, and a dispersing paddle at a speed of 500 rpm, vacuumize and stir at room temperature for 12 minutes, and cool with condensed water as needed. Make sure that the temperature of the base rubber is below 50°C; add the crosslinking agent, chain extender and deep curing agent in sequence, and vacuumize a...

Embodiment 2

[0040] Material composition:

[0041]

[0042]

[0043] Preparation:

[0044]The above table shows the composition of raw materials in Example 2. Mix vinyltrimethoxysilane and plasticizer at a ratio of 1:1 by mass and stir evenly, stir at 110°C for 3 hours, cool and seal for later use; Add dimethyl siloxane, plasticizer, filler, thixotropic agent and pigment into the vacuum kneader in sequence, and dehydrate under vacuum at 140°C for 3 hours at a speed of 30rpm to obtain the base rubber; put the base rubber into the three-roll mill Grind to a fineness of 30 μm, and cool to room temperature; put the ground rubber into a dynamic mixer, use a planetary paddle at 40 rpm, and a dispersing paddle at a speed of 350 rpm, vacuumize and stir at room temperature for 10 minutes, and cool with condensed water as needed to ensure The temperature of the base glue is below 50°C; add the crosslinking agent, chain extender and deep curing agent in turn, vacuumize and stir for 20 minutes;...

Embodiment 3

[0047] Material composition:

[0048]

[0049]

[0050] Preparation:

[0051] The above table shows the composition of raw materials in Example 3. Mix magnesium chloride and plasticizer at a ratio of 1:1 by mass and stir evenly, stir at 140°C for 3 hours, cool and seal for later use; mix α,ω-dihydroxy polydimethylsiloxane Alkanes, plasticizers, fillers, thixotropic agents and pigments were added to the vacuum kneader in turn, and the base rubber was obtained after vacuum dehydration at 130 °C for 3 hours at a speed of 30 rpm; the base rubber was put into a three-roll mill and ground to a fineness of 30μm, cooled to room temperature; put the ground rubber base into a power mixer, with a planetary paddle of 80rpm and a dispersing paddle of 100rpm, vacuumize and stir for 8min at room temperature, and cool with condensed water as needed to ensure that the temperature of the base rubber is at 50 Below ℃; add cross-linking agent, chain extender and deep layer curing agent in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com