Electronic frying and baking dual-purpose stove

A dual-purpose furnace, electric technology, applied in applications, kitchen utensils, home utensils, etc., can solve the problems of practicability to be improved, complex structure, etc., to improve the quality of dried fruits, improve business vitality, and save space.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

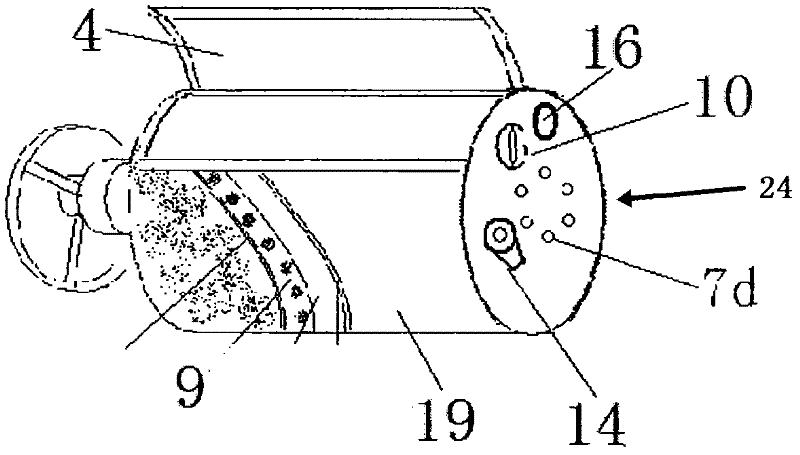

[0076] Embodiment one sees figure 1 ;

[0077] A combined structure with fixed brackets, including adjustable speed reduction motors, small blowers, bearings, conductive slip rings, metal plates, etc.;

[0078] Such as figure 1 As shown, on a closed housing warehouse 19 with an axis of symmetry; the front of the housing is provided with a warehouse door 4 that is large enough to open and close, and the warehouse door and the doorway adopt a conventional hinge structure and buckle coupling. Winding or wrapping the electric heating component 9 on the outer wall of the inner liner 19 of the closed shell;

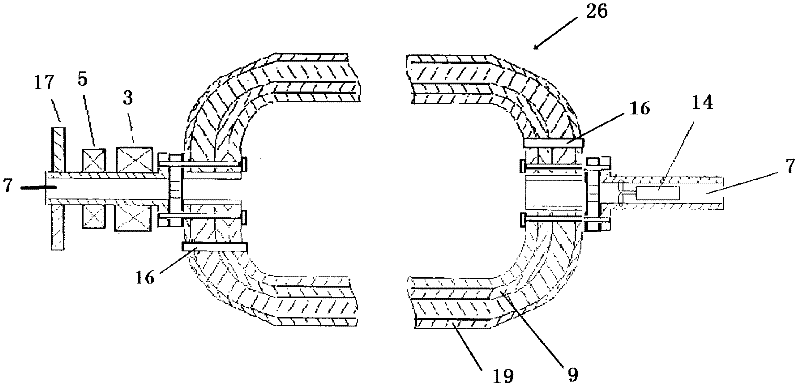

[0079] Such as figure 2 Shown is a sectional view of the warehouse 19, and a thermostat 10 is set to connect the contacts of the temperature-sensing head to the electric heating assembly 9. After reserving the position of the wire and the position of the vent pipe 16 next to the electric heating component, wrap the thermal insulation material to form a thermal insulation l...

Embodiment 2

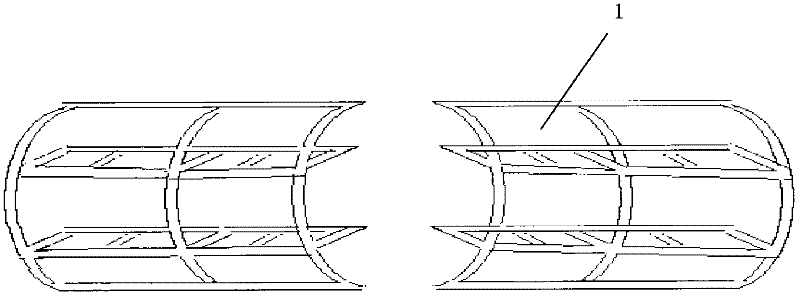

[0094] Figure 4 and Figure 5 It is a structure in which the geared motor 13 is arranged on the frame 2, which is a relatively traditional motor arrangement method. In order to integrate the warehouse 19 and the geared motor 13 as a whole and reduce the occupied space of the dual-purpose furnace, the present invention will provide a combined structure that integrates the warehouse assembly and the geared motor. This structure comprises that "the warehouse assembly 24 with blower" and the stator or the rotor of the small reduction motor 33 are respectively fixed, forming two types of combined equipment. Such as Image 6 As shown, it is a combined working state in which "machine heads" of two forms and four styles are integrated on one support 2. This integrated structure is called "head assembly", that is, the warehouse and the motor are integrated into one structure, such as Image 6 as shown,

[0095] 20 is the style in which the "storage assembly 24 with a blower" is cou...

Embodiment 3

[0103] The present invention integrates the warehouse part with the deceleration motor to make the structure compact, and the advantage of the compact structure is that it provides a structure that fully utilizes the heat energy of the motor to provide the warehouse with an air source. The geared motor itself is equipped with a heat dissipation fan. The present invention properly transforms the air passage structure of its heat dissipation fan, which can save the blower 14 provided on the warehouse, so that the geared motor can provide adjustable cooling for the cargo warehouse 19 while radiating heat for itself. Continuous cold air to promote dehydration of food. A method provided by the present invention is a method of introducing the heat dissipation air of the motor, which is to introduce the heat dissipation air of the deceleration motor into the warehouse 19 by adopting the principle of an axial flow fan. Another method provided by the present invention is the method of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com