Potato dough curing method

A potato and dough technology, applied in the fields of application, food preparation, food science, etc., can solve the problems of no potato dough ripening process, and achieve the effect of reducing fluctuation and enhancing heat transfer effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

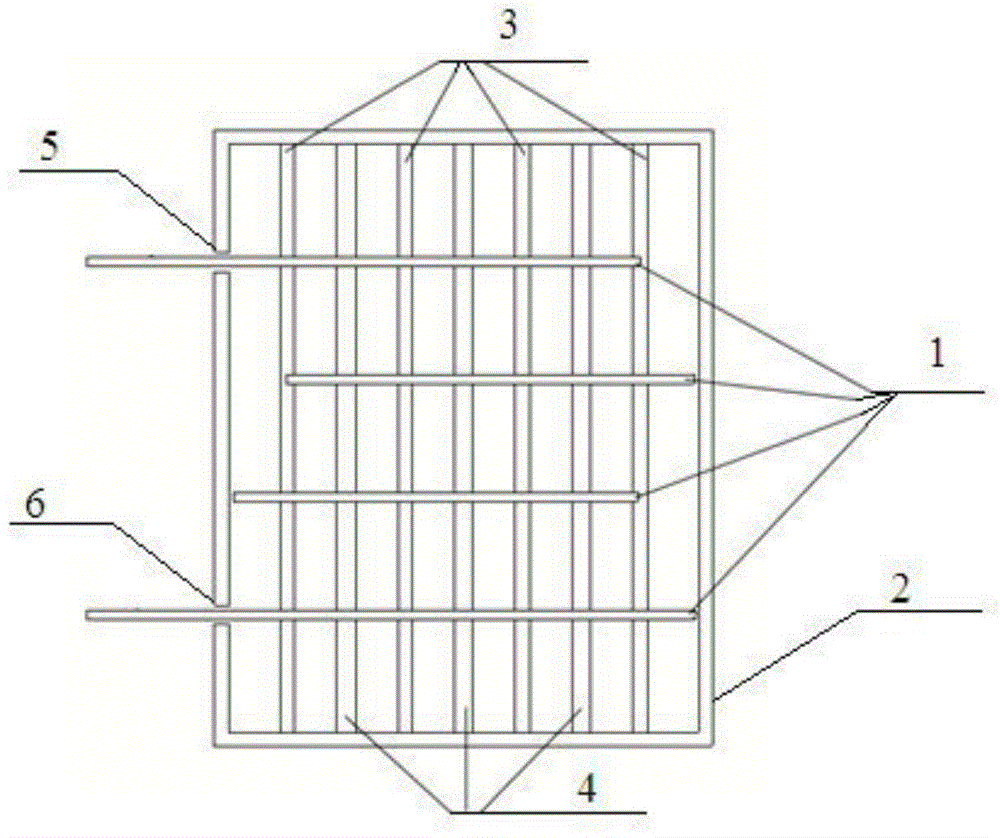

Image

Examples

Embodiment 1

[0039] The raw materials of the potato dough are 35g of whole potato flour, 65g of wheat flour and 35g of water. The curing time is 40 minutes, the curing temperature is 30°C, and the curing humidity is 90%.

[0040] The temperature setting value of the curing box is 30° C., and the humidity setting value is 90%. The controller compares the actual temperature T with the temperature set point T o compare when T o -T≥5℃, then the selected temperature T s is 36°C, the selected flow velocity is 0.8m / s, when 0o -Ts is 32°C, the selected flow velocity is 0.3m / s, when 0o s is 26°C, the selected flow velocity is 0.3m / s, when T-T o ≥5℃, then the selected temperature T s is 24°C, the selected flow velocity is 0.8m / s.

[0041] The potato dough is placed on the uppermost conveyor belt and ripens as it travels. The gluten content increases, the toughness and cohesion of the dough are better, and the noodles will not break when processing the noodles.

Embodiment 2

[0043] The raw materials of the potato dough are 50g of whole potato flour, 50g of wheat flour and 38g of water. The curing time is 90 minutes, the curing temperature is 20° C., and the curing humidity is 80%.

[0044] The temperature setting value of the curing box is 20° C., and the humidity setting value is 80%. The controller compares the actual temperature T with the temperature set point T o compare when T o -T≥5℃, then the selected temperature T s is 30°C, the selected flow velocity is 0.5m / s, when 0o -Ts is 24°C, the selected flow rate is 0.1m / s, when 0o s is 17°C, the selected flow rate is 0.1m / s, when T-T o ≥5℃, then the selected temperature T s is 10°C, the selected flow velocity is 0.5m / s.

[0045] The potato dough is placed on the uppermost conveyor belt and ripens as it travels. The gluten content increases, the toughness and cohesion of the dough are better, and the noodles will not break when processing the noodles.

Embodiment 3

[0047] The raw materials of the potato dough are 40g of whole potato flour, 50g of wheat flour, 38g of water and 10g of protein powder. The curing time is 120 minutes, the curing temperature is 25° C., and the curing humidity is 85%.

[0048] The temperature setting value of the curing box is 20° C., and the humidity setting value is 80%. The controller compares the actual temperature T with the temperature set point T o compare when T o -T≥5℃, then the selected temperature T s 30℃, when 0o -Ts at 24°C, when 0o s 17°C when T-T o ≥5℃, then the selected temperature T s is 10°C.

[0049] The potato dough is placed on the uppermost conveyor belt and ripens as it travels. The gluten content increases, the toughness and cohesion of the dough are better, and the noodles will not break when processing the noodles.

[0050] Implementation four

[0051] The raw materials of the potato dough are 50g of whole potato flour, 50g of wheat flour and 38g of water. The curing time is 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com