Extrusion and molding method for cup-shaped part and special extrusion die

A technology for extrusion forming and cup-shaped parts, applied in the direction of metal extrusion dies, etc., can solve the problems of high equipment investment cost, large extrusion force, large tonnage of forming equipment, etc., to reduce equipment investment cost and small extrusion area. , the effect of reducing the single extrusion force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

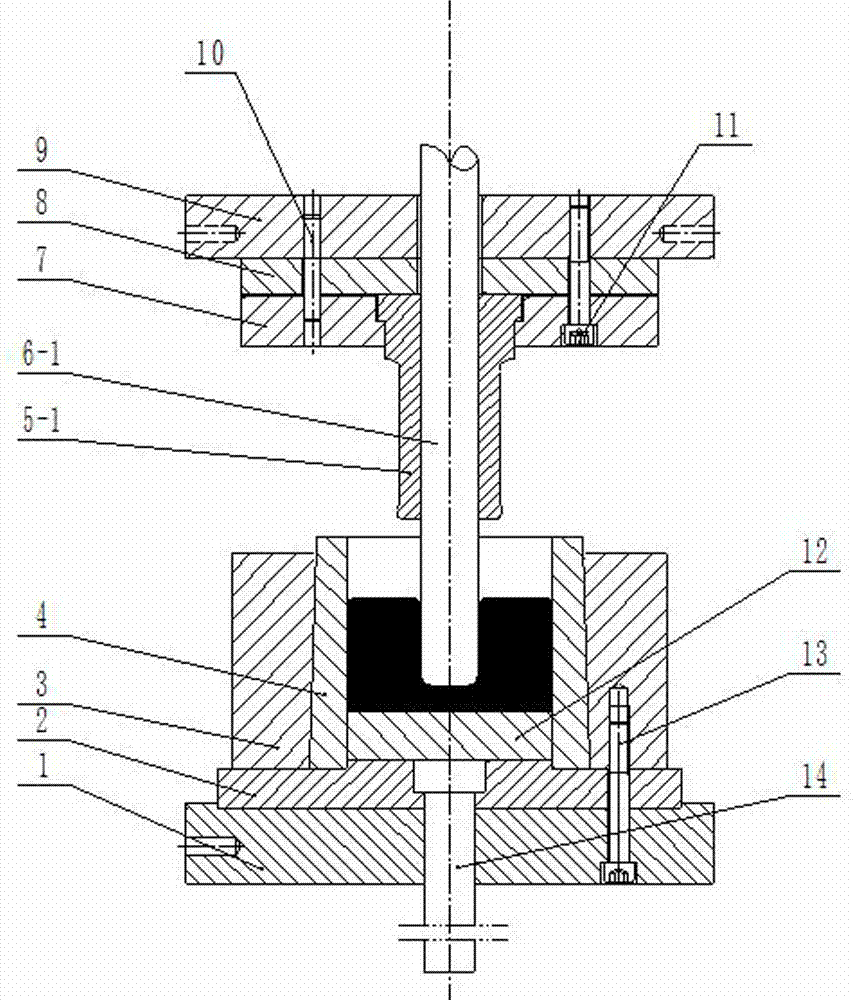

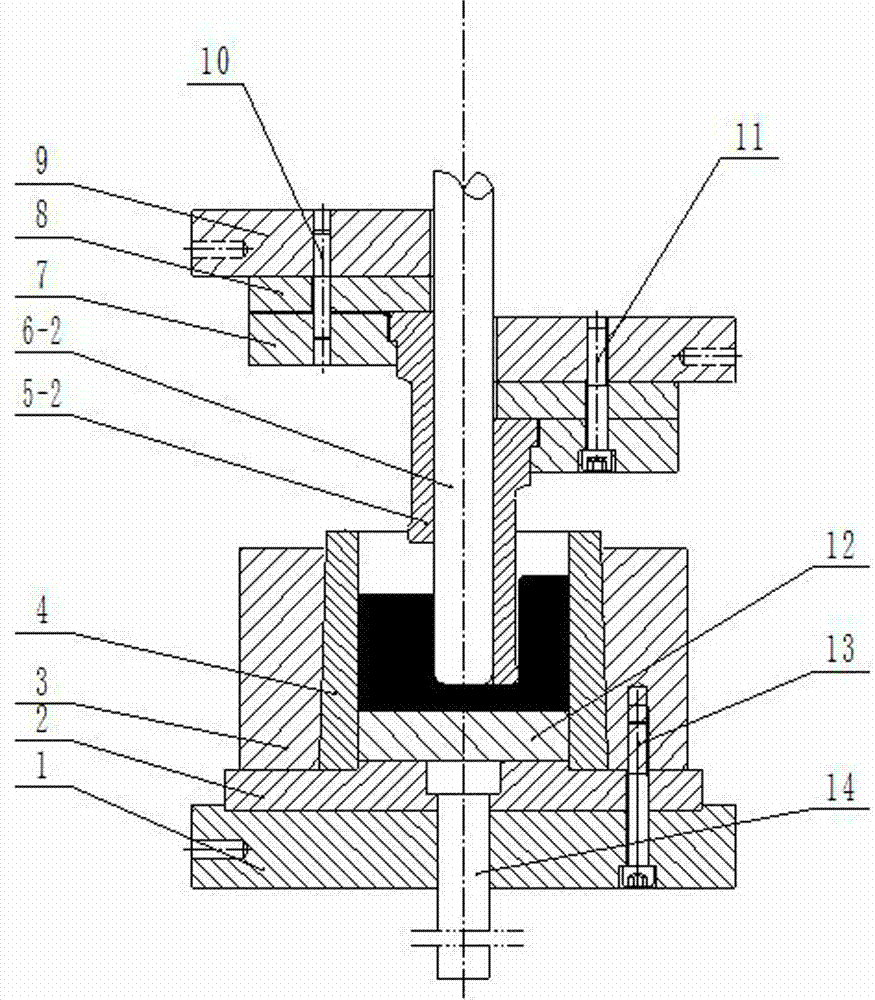

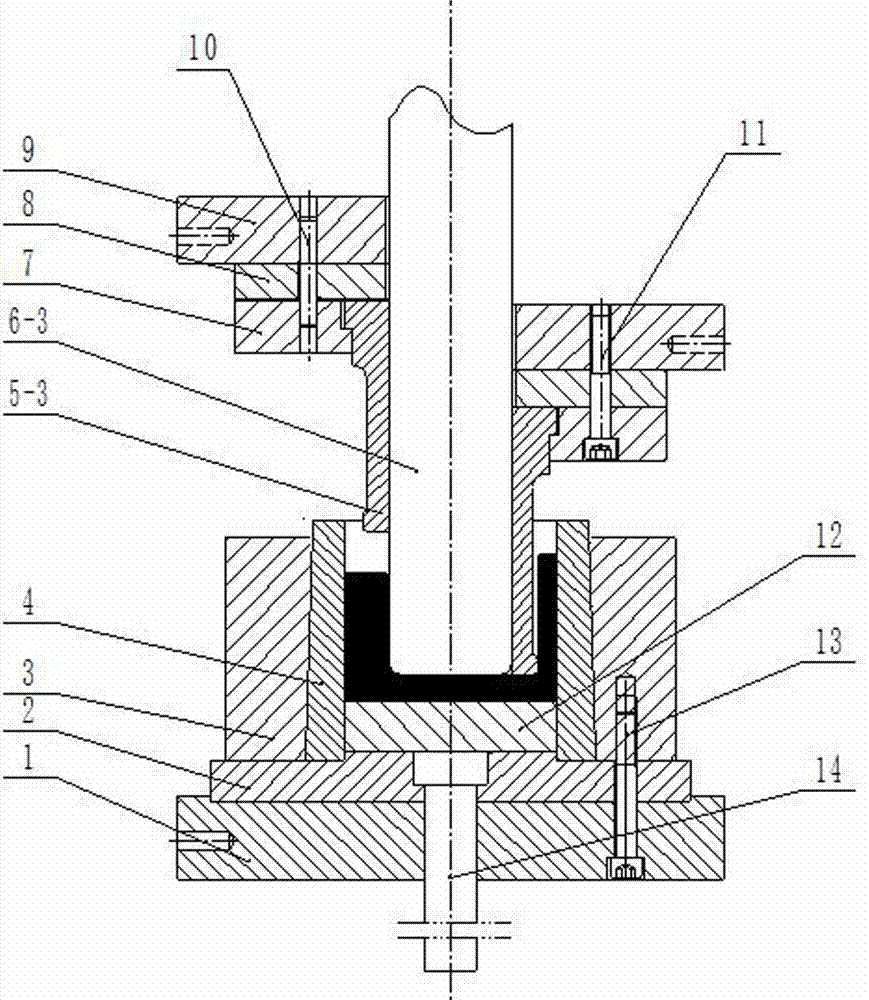

[0023] Embodiment of a kind of cup extrusion method of the present invention: as Figure 1 ~ Figure 3 As shown, the extrusion method includes the following steps, 1) will be as Figure 4 Diameter shown is D 0 , the height is h 0 The blank is put into the die of the extrusion molding die installed on the double-acting hydraulic press. The double-acting hydraulic press has two power output ends of the outer cylinder and the inner cylinder. The extrusion molding mold includes an inner punch 6-1, and the inner convex The mold cover is provided with an outer punch 5-1, the outer punch 5-1 is guided and slidably matched with the inner punch, the outer punch 5-1 is connected with the outer cylinder of the double-acting hydraulic press, and the inner punch 6-1 is connected with the The inner cylinder block of the double-acting hydraulic press is connected by transmission, and the double-acting hydraulic press is started. The inner cylinder body of the double-acting hydraulic press m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com