Molecular sieve based catalyst and preparation and application thereof

A molecular sieve and catalyst technology, which is applied in the field of aromatics preparation, can solve the problems of large investment in fluidized beds, catalyst wear, and increased product cost, and achieve the effects of prolonging life, improving stability, and increasing activity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] 1. Preparation of HZn-ZSM-5 molecular sieve catalyst

[0027] 1) Using zinc nitrate as raw material, Zn-ZSM-5 molecular sieve was prepared by in situ synthesis method to control SiO 2 / Al 2 o 3 (Molar ratio) = 100, SiO 2 / Zn (molar ratio) = 200.

[0028] 2) with silica sol (SiO 2 ·nH 2 O) is a binder, and its content is controlled to account for 10% of the mass of the catalyst, and the Zn-ZSM-5 molecular sieve is extruded and roasted to obtain a strip-shaped Zn-ZSM-5 molecular sieve.

[0029] 3) Treat the strip Zn-ZSM-5 molecular sieve with 0.1M NaOH solution, that is, stir for 1 hour at 80°C and the mass ratio of NaOH solution to Zn-ZSM-5 molecular sieve is 30, and then dry it at 120°C .

[0030] 4) Using 0.5 mol / L ammonium chloride solution, at 90° C., under the condition that the mass ratio of the solution to the molecular sieve solid is 10:1, ion-exchange the Zn-ZSM-5 molecular sieve three times, each time for 2 hours.

[0031] 5) Washing, drying, and then cal...

Embodiment 2~4

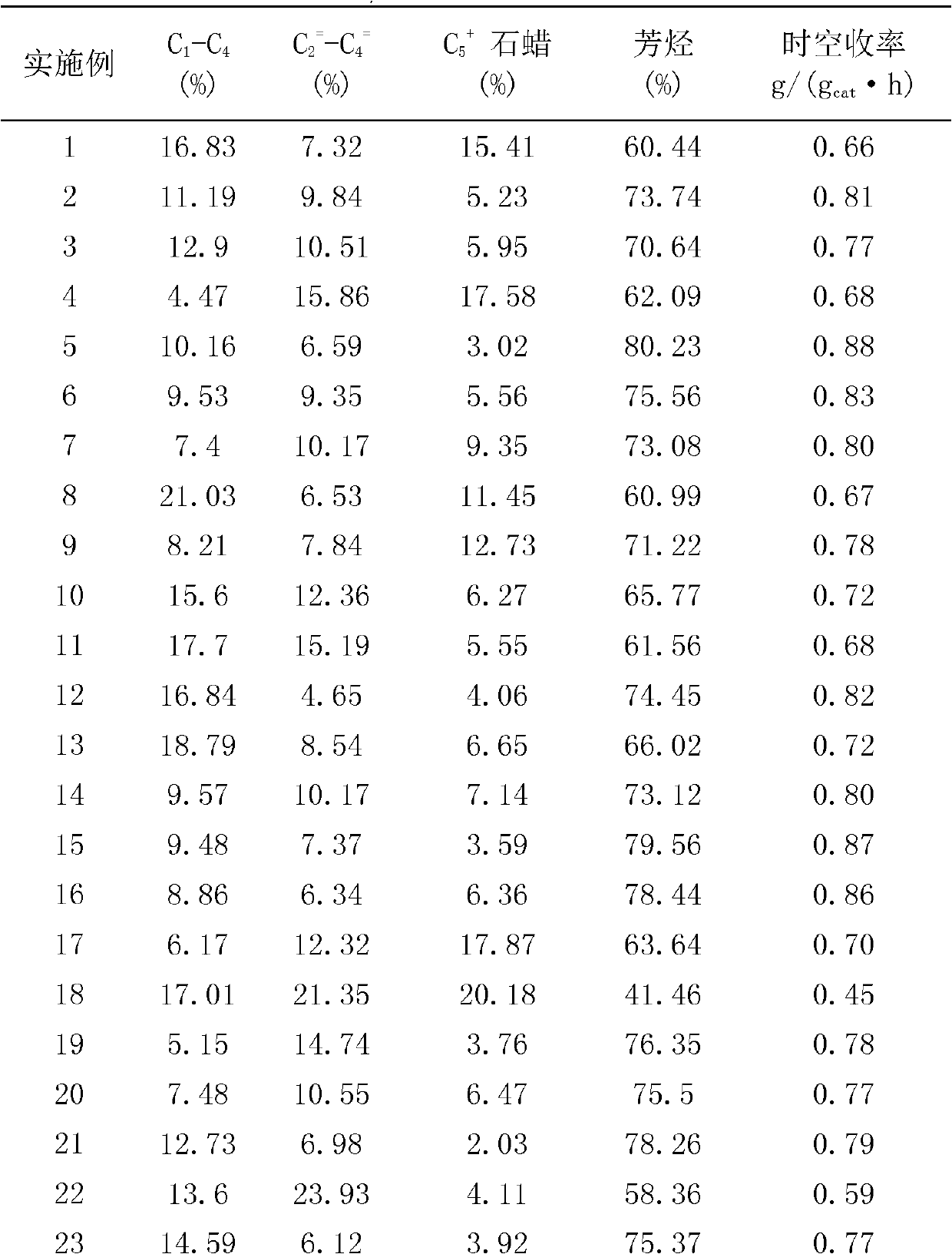

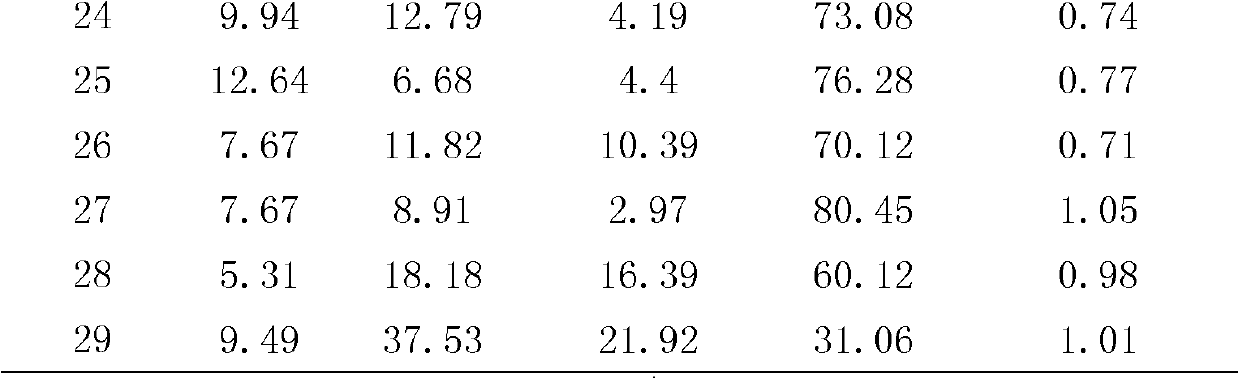

[0035] SiO 2 / ZnO (molar ratio) is controlled to be 150,100,50 respectively, all the other steps are with embodiment 1. The prepared HZn-ZSM-5 molecular sieve catalyst was used as an MTA catalyst, and the MTA reaction was carried out under the same conditions as in Example 1. The product distribution is shown in Table 1.

Embodiment 5

[0037] 1. Preparation of HAg-ZSM-5 molecular sieve catalyst

[0038] Using silver nitrate as raw material, Ag-ZSM-5 molecular sieves were prepared by in situ synthesis to control SiO 2 / Al 2 o 3 (molar ratio)=100 and SiO2 / Ag (molar ratio)=200. All the other steps are the same as in Example 1.

[0039] 2. MTA reaction

[0040] The prepared HAg-ZSM-5 molecular sieve catalyst was used as the MTA catalyst, and the MTA reaction was carried out under the same conditions as in Example 1. The product distribution is shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com