Clay-based heavy metal thermal curing agent and its method for curing heaving metal

A technology of thermal curing agent and heavy metal, applied in the field of soil pollution remediation, can solve the problems of few heavy metal detoxification studies, short stabilization time, high cost of curing agent, and achieve the effect of optimistic industrialization prospect, wide application prospect and good stabilization effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

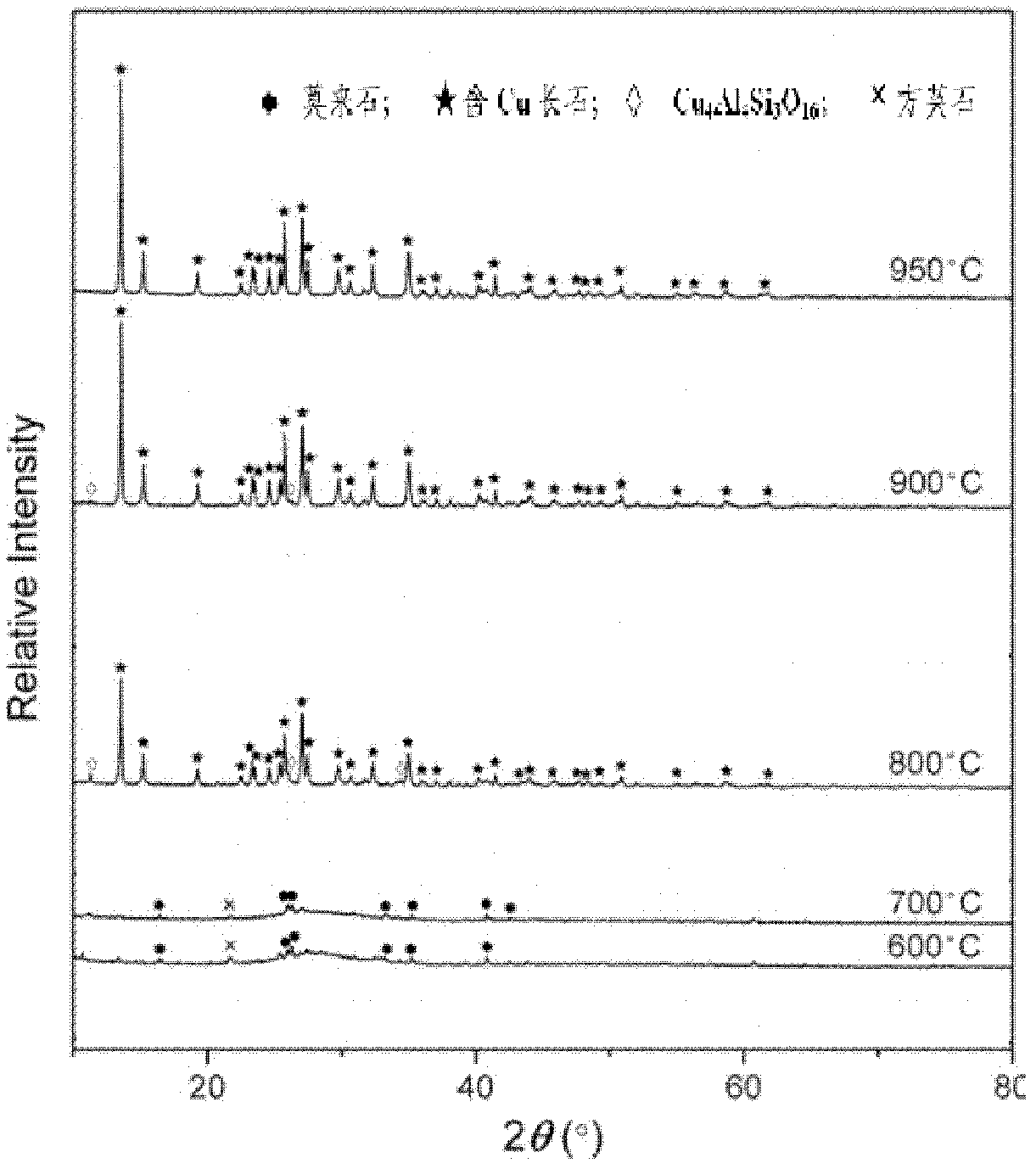

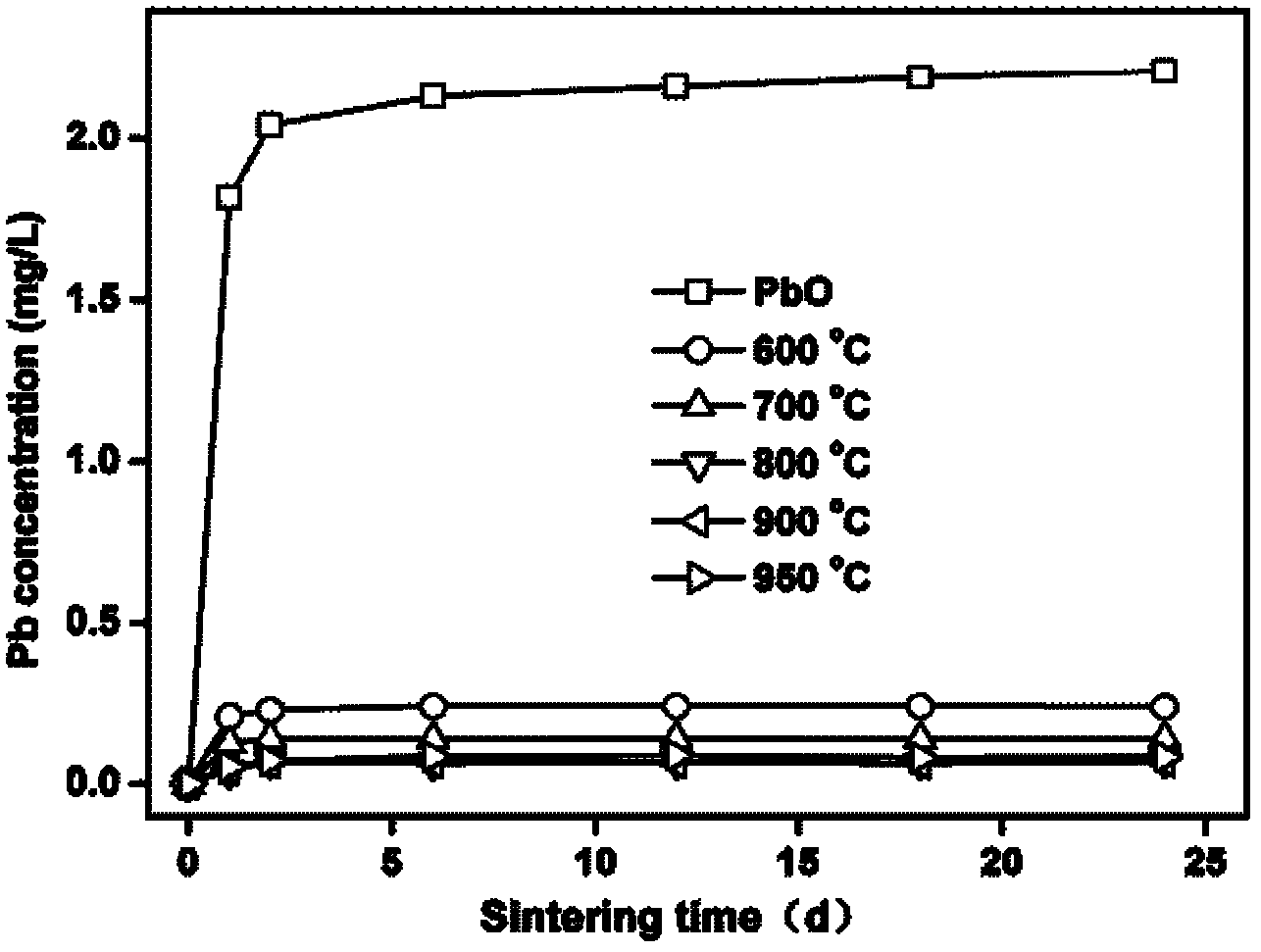

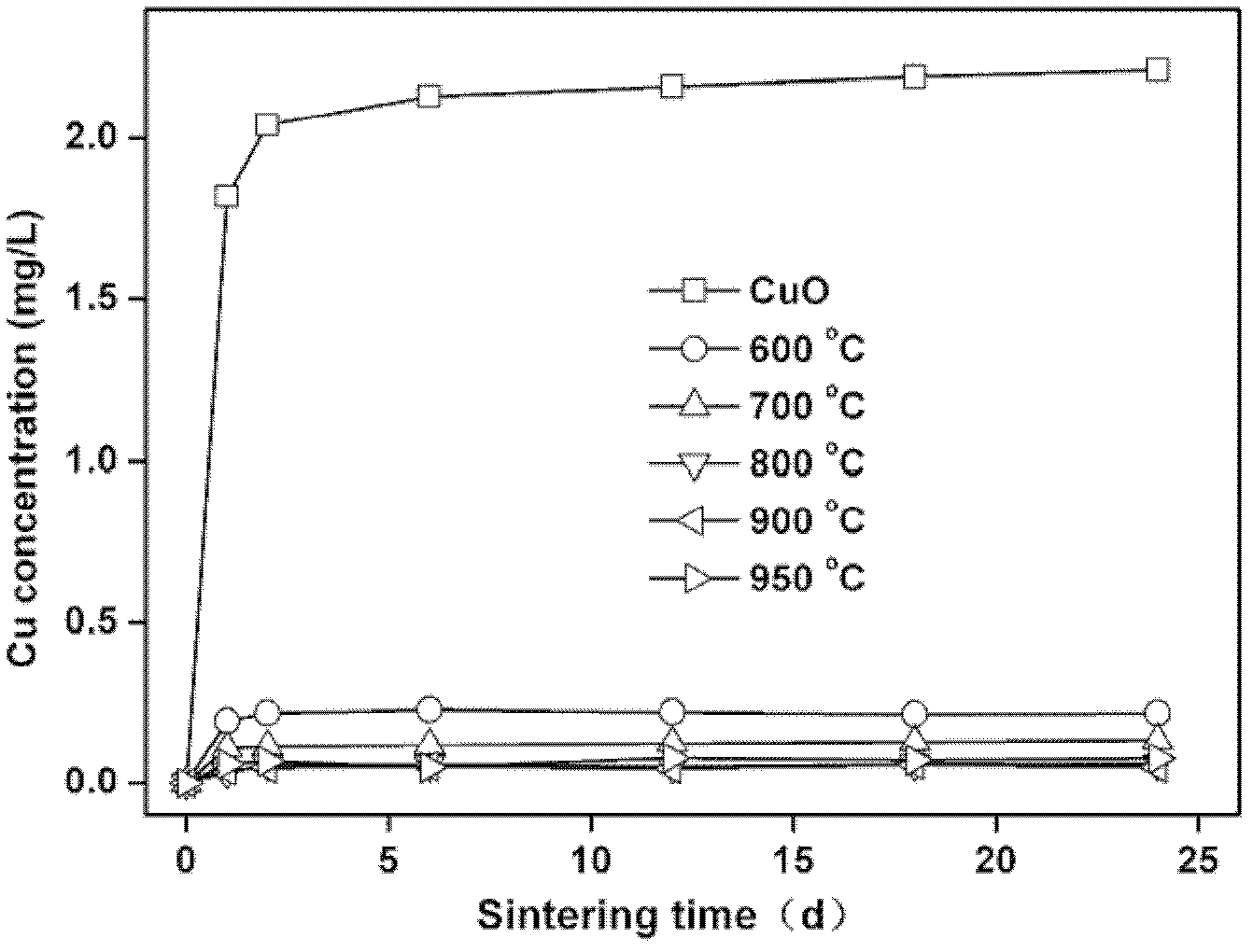

[0042] Example 1: Clay-based heavy metal thermal curing agent and its curing application and curing effect evaluation on a single heavy metal

[0043] The heavy metal thermosetting agent based on clay of the present embodiment, its component and content are as follows, by total mass fraction 100%, comprise clay (mullite powder) 40%, iron oxide 15%, fly ash 20% and stone powder 25% %. The above components are mixed evenly according to their contents to obtain the clay-based heavy metal thermosetting agent.

[0044] The single heavy metal is Cu.

[0045] The heavy metal thermosetting agent based on clay of the present embodiment comprises the following steps to the curing method and curing effect evaluation of heavy metals:

[0046] (1) CuO is mixed with the heavy metal thermosetting agent based on clay respectively in different ratios of mass ratio 1: 1, 1: 5, 1: 10, 1: 15 and 1: 20;

[0047] (2) Rotate and mix samples with different mass ratios in a mixer for 2 hours;

[0...

Embodiment 2

[0053] Example 2: Application of clay-based heavy metal thermal curing agent to thermal curing of mixed heavy metals and evaluation of curing effect

[0054] The heavy metal thermosetting agent based on clay of the present embodiment, its component and content are as follows: by mass fraction 100%, clay 40% (bentonite 10%, kaolin 10%, mullite powder 10%, illite powder 10%), Iron oxide 15%, fly ash 30% and stone powder 15%. The above components are mixed evenly according to their contents to obtain the clay-based heavy metal thermosetting agent.

[0055] The mixed heavy metals are seven kinds of Pb, Zn, Ni, Cd, Cu, Hg and Mg, and the heavy metals are in the form of oxides. In this embodiment, the mixed heavy metals are composed in the same mass ratio.

[0056] The heavy metal thermosetting agent based on clay of the present embodiment comprises the following steps to the curing method and curing effect evaluation of heavy metals:

[0057] (1) mixing heavy metals with clay-bas...

Embodiment 3

[0062] Example 3: Application of clay-based heavy metal thermal curing agent to thermal curing of heavy metals in heavy metal-contaminated soil at electronic waste dismantling site and evaluation of curing effect

[0063] The clay-based heavy metal thermal curing agent of this embodiment has the following components and contents: based on 100% by mass fraction, 60% of kaolin, 5% of iron oxide, 20% of fly ash and 15% of stone powder. The above components are mixed evenly according to their contents to obtain the clay-based heavy metal thermosetting agent.

[0064] The heavy metal-contaminated soil at the e-waste dismantling site described in this example is the soil at an e-waste dismantling site in Longtang Town, Qingyuan City. After the soil was collected, it was digested with strong acid and analyzed by ICP-AES. The heavy metal components were as follows: Cr 56.17mg / kg, Ni 29.22mg / kg, Pb 8161.31mg / kg, Cd 0.94mg / kg, Hg 232.38mg / kg, Cu 511.59mg / kg.

[0065] The thermal curing...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com