Preparation method for silicon carbide ceramic tube or rod

A technology of silicon carbide ceramics and silicon carbide tubes, applied in chemical instruments and methods, ceramic molding machines, clay preparation devices, etc., can solve problems such as difficult control, poor strength, corrosion resistance, high temperature stability, and low yield. Achieve the effects of small shape and size restrictions, uniform particle dispersion, and excellent corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

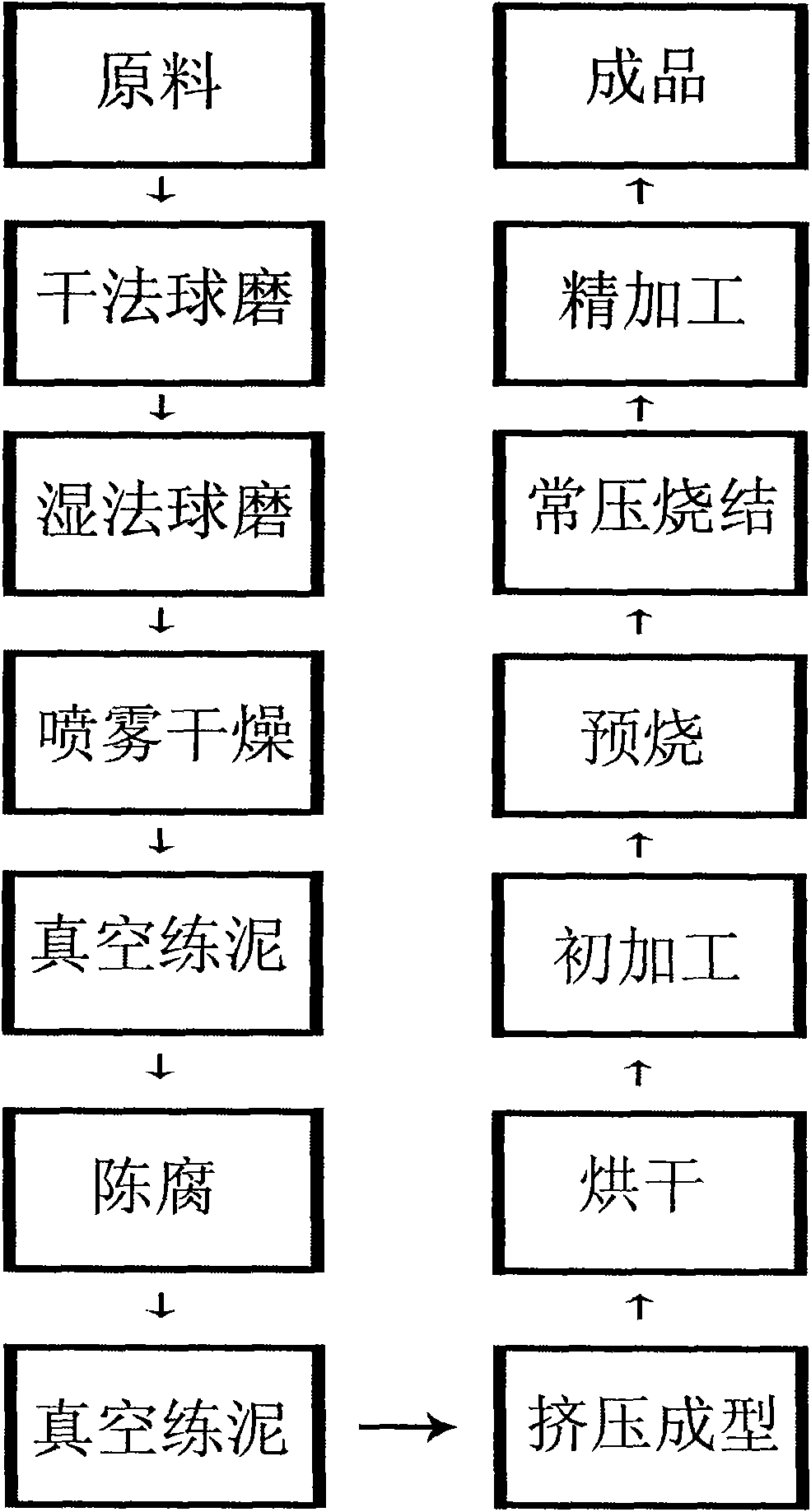

Method used

Image

Examples

Embodiment 1

[0032] 1), the average particle diameter is 0.5 micron, the silicon carbide powder that is 98.5% by weight, the graphite powder of 1%, the boron carbide powder of 0.5% are dry-milled for 1 hour;

[0033] 2) Add 100% water, 0.2% tetramethylammonium hydroxide, 1% polyethylene glycol, 0.5% oleic acid, and 2% polyethylene glycol to the powder after dry grinding. Alcohol wet ball milling for 8 hours to form a silicon carbide slurry with a solid content of 50%;

[0034] 3) Using a spray drying process to granulate the wet-milled silicon carbide slurry to obtain silicon carbide granulated powder; the spray drying is carried out with a spray dryer, and the process parameters are: the inlet temperature is 230°C, and the outlet temperature is 105°C, atomization pressure 1.2MPa;

[0035] 4), take the weight of granulated powder as 100%, add the water that is 13% of granulated powder weight in the granulated powder after spray-drying and carry out vacuum mud refining in vacuum mud refini...

Embodiment 2

[0045] 1) The silicon carbide powder with an average particle size of 0.6 microns, 94% by weight, 2% yttrium oxide, 1.5% aluminum oxide, and 2.5% magnesium oxide by weight were dry ball milled for 2 hours;

[0046] 2) Add 100% water, 0.2% tetramethylammonium hydroxide, 1% polyethylene glycol, 0.5% oleic acid, and 2% polyethylene glycol to the powder after dry grinding. Alcohol wet ball milling for 8 hours to form a silicon carbide slurry with a solid content of 50%;

[0047] 3) Using a spray drying process to granulate the wet-milled silicon carbide slurry to obtain silicon carbide granulated powder; the spray drying is carried out using a spray dryer, and the process parameters are: the inlet temperature is 230°C, the outlet temperature 105°C, atomization pressure 1.2MPa;

[0048]4), take the weight of granulated powder as 100%, add the water that is 15% of granulated powder weight in the granulated powder after spray-drying and carry out vacuum mud refining in vacuum mud re...

Embodiment 3

[0058] 1), the silicon carbide powder that the average particle diameter is 0.5 micron, percentage by weight is 70%, the boron carbide powder that is 1 micron, 22%, the aluminum oxide powder of 4%, the yttrium oxide powder of 3% , 1% dry ball milling of lanthanum oxide powder for 1 hour;

[0059] 2), the dry-milled powder is sequentially added in a ball mill to 100% water by weight of the main raw material, 0.2% ammonium polyacrylate, 1% sucrose fat, 0.5% stearic acid, and 2% water-soluble acrylic acid Resin is then wet ball milled for 8 hours to prepare a silicon carbide slurry with a solid content of 50%;

[0060] 3) Using a spray drying process to granulate the wet-milled silicon carbide slurry to obtain silicon carbide granulated powder; the spray drying is carried out with a spray dryer, and the process parameters are: the inlet temperature is 220°C, and the outlet temperature is 105°C, the atomization pressure is 1.2MPa;

[0061] 4), take the weight of granulated powde...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Bending strength | aaaaa | aaaaa |

| Fracture toughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com