Semi-solid multi-blank extruding process and apparatus for forming double-layer composite pipe

A double-layer composite and extrusion forming technology is applied in the direction of metal extrusion, metal extrusion dies, metal extrusion control equipment, etc., and can solve the problems of semi-solid multi-blank extrusion and connection of double-layer composite pipes that have not been found. Gap and other problems, to achieve the effect of reducing energy consumption, improving product quality, and reducing cost investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

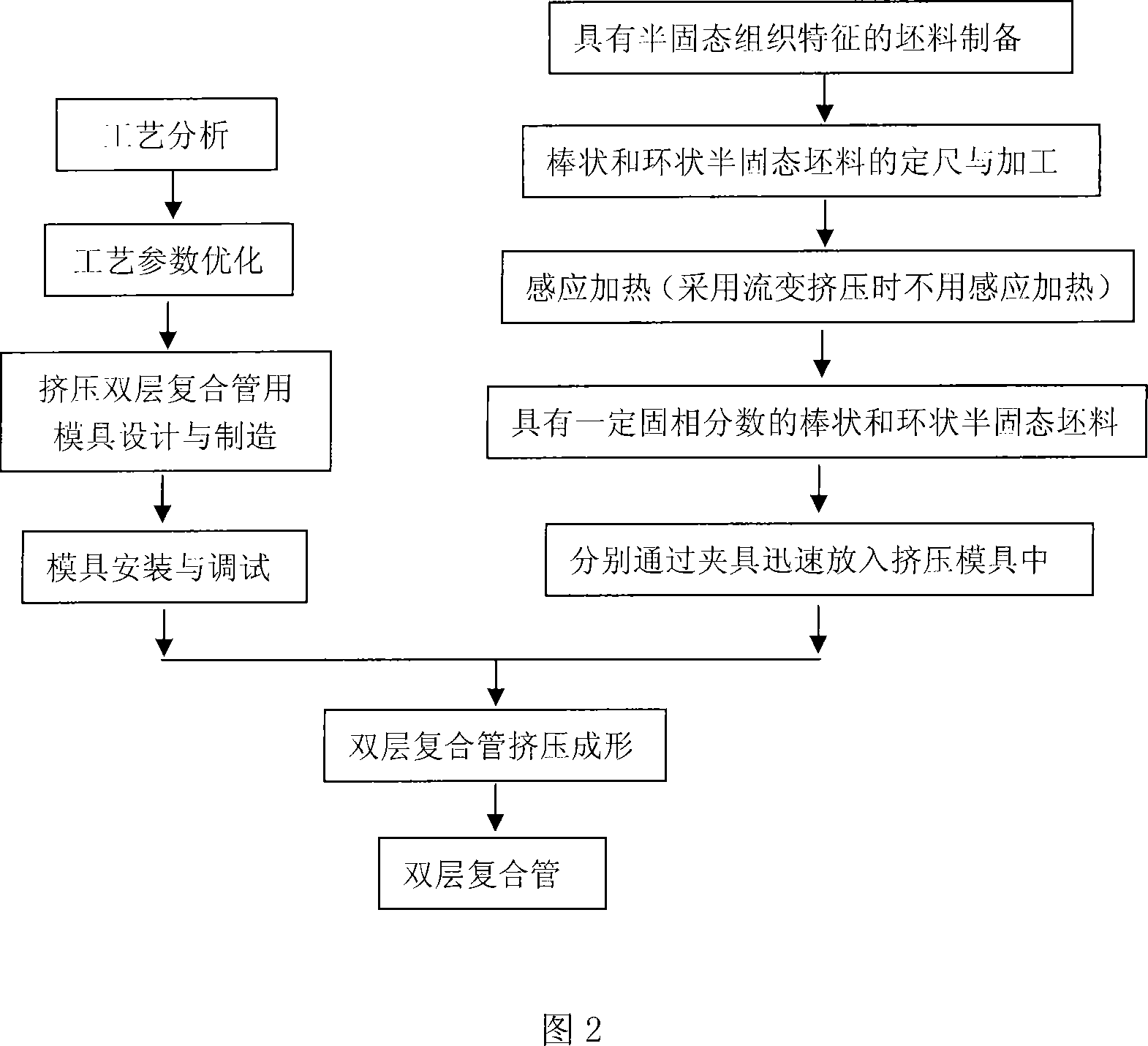

[0031] Below in conjunction with accompanying drawing, technical scheme of the present invention is described further:

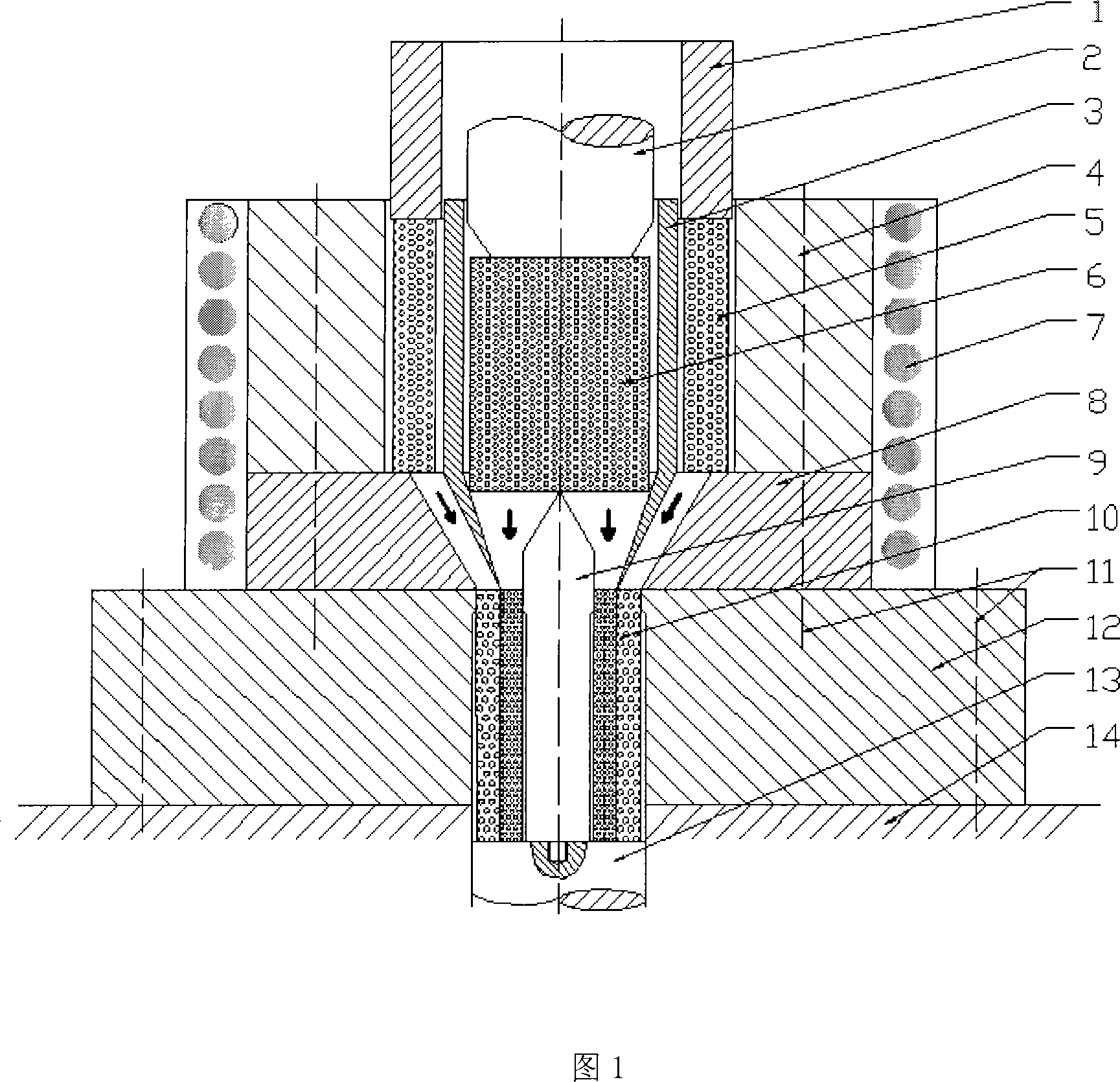

[0032] As shown in Figure 1, 1-outer extrusion rod; 2-inner extrusion rod; 3-inner extrusion cylinder; 4-outer extrusion cylinder; 5-annular semi-solid billet; 6-rod-shaped semi-solid billet; 7 -heating ring; 8-forming guide plate; 9-mandrel; 10-layer composite pipe; 11-die fixing screw; 12-extrusion die; 13-ejector rod; 14-worktable.

[0033] Figure-1 The connection relationship of each part in the mold assembly diagram: the outer extrusion rod 1 and the inner extrusion rod 2 are respectively fixed on the outer slider and inner slider of the double-action press, so that they can move up and down with the slider. An annular semi-solid billet 5 with a certain solid fraction is placed between the inner extrusion barrel 3 and the outer extrusion barrel 4 , and a rod-shaped semi-solid billet 6 with a certain solid fraction is placed inside the inner extrusion ba...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com