Method for preparing alpha-phenylethanol catalyst through hydrogenation of acetophenone and application

A technology for the preparation of catalysts and hydrogen, which is applied in the preparation of organic compounds, metal/metal oxide/metal hydroxide catalysts, chemical instruments and methods, etc. Problems such as low conversion rate and reduced catalyst use strength, to achieve good mass transfer/heat transfer performance, uniform distribution of active components, and improved mass transfer and heat transfer performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

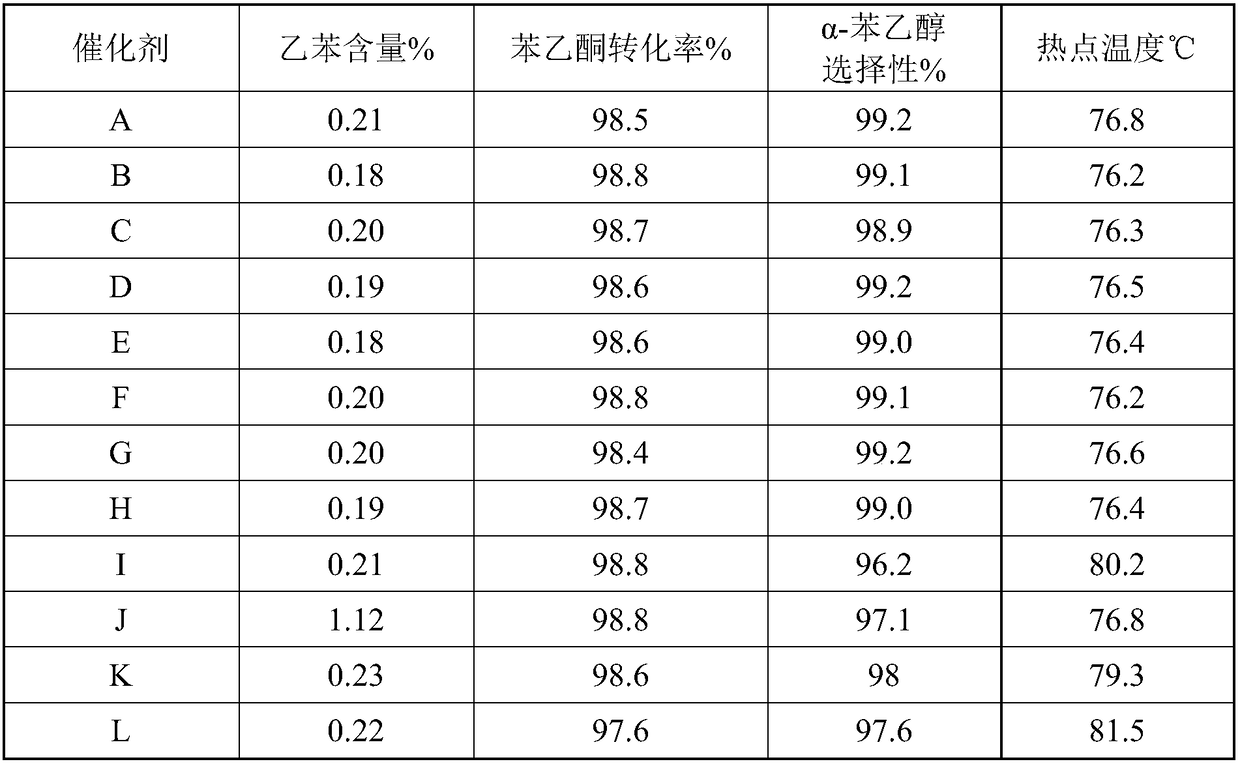

Examples

Embodiment 1

[0042] Weigh 11.67g of zinc nitrate to prepare a 1mol / L aqueous solution, carry out co-precipitation reaction with 10wt% sodium carbonate aqueous solution, control the reaction temperature at 60°C, and pH=6.8; after the reaction is completed, age at 75°C for 20min to obtain slurry 1.

[0043] Weigh 82.55g of copper nitrate and 8.48g of bismuth nitrate to prepare a mixed aqueous solution of 1mol / L, and add dropwise to slurry 1 together with 10wt% sodium carbonate aqueous solution to carry out coprecipitation reaction, control the reaction temperature to 45°C, and pH=7.2; After completion, it was aged at 65° C. for 2 hours to obtain slurry 2 .

[0044] After the aging was completed, 183.3 g of 30% silica sol was added to the slurry 2, mixed evenly, filtered, washed, dried at 100°C for 6 hours, and then calcined at 280°C for 4 hours.

[0045] After the calcination is completed, add 2g of PMMA to the catalyst powder, mix evenly, and press into tablets. The molded catalyst was sub...

Embodiment 2

[0048] Weigh 25.19g of zinc chloride to prepare a 1.5mol / L aqueous solution, carry out co-precipitation reaction with 15wt% sodium bicarbonate aqueous solution, control the reaction temperature at 65°C, and pH=7.0; after the reaction is completed, age at 70°C for 25min to obtain a slurry 1.

[0049] Take by weighing 69.36g cupric chloride and 4.06g bismuth chloride and be mixed with the mixed aqueous solution of 1.5mol / L, and add dropwise in slurry 1 together with 15wt% sodium carbonate aqueous solution and carry out co-precipitation reaction, control reaction temperature 40 ℃, PH= 7.0; aging at 70° C. for 2.5 hours after completion of the reaction to obtain slurry 2.

[0050] After aging, add 41g of fumed silica with a particle size of 5-10nm to the slurry 2, mix evenly, filter, wash, dry at 105°C for 7h, and bake at 300°C for 5h.

[0051] After the calcination is completed, 4 g of microcrystalline cellulose is added to the catalyst powder, mixed evenly, and then pressed int...

Embodiment 3

[0054] Weigh 25.84g of zinc sulfate to prepare a 2mol / L aqueous solution, carry out co-precipitation reaction with 20wt% potassium carbonate aqueous solution, control the reaction temperature to 70°C, pH=7.2; after the reaction is completed, age at 65°C for 30min to obtain slurry 1.

[0055] Weigh 100.31g of copper sulfate and 6.06g of bismuth sulfate to prepare a mixed aqueous solution of 2mol / L, and dropwise add it to slurry 1 together with 20wt% potassium carbonate aqueous solution to carry out coprecipitation reaction, control the reaction temperature to 35°C, and pH=6.8; After completion, it was aged at 75°C for 3 hours to obtain slurry 2.

[0056] After the aging was completed, 38.9 g of diatomite with a silicon dioxide content of 90% was added to the slurry 2, mixed evenly, filtered, washed, dried at 110°C for 8 hours, and calcined at 320°C for 6 hours.

[0057] After the calcination is completed, add 6 g of scallop powder to the catalyst powder, mix evenly, and press i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com