Halogen-free flame-retardant high-temperature-resistant polyester elastomers and a preparation method therefor

A technology of high temperature resistant polyester and polyester elastomer, applied in halogen-free flame retardant and high temperature resistant polyester elastomer and its preparation, in the field of automobile engine peripheral wire industry, can solve problems such as high temperature resistance and flame retardant efficiency, and avoid the Degradation behavior, increasing flame retardant char formation, and the effect of broad market prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

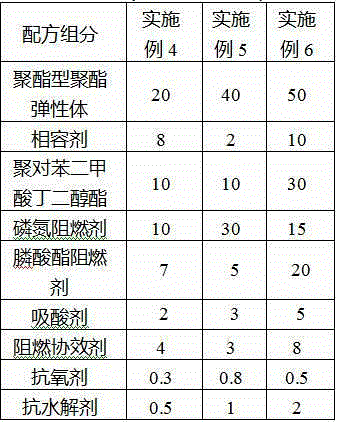

Examples

Embodiment 1

[0045] Polyester type polyester elastomer 40 parts

[0046] Polybutylene terephthalate 15 parts

[0047] 3 parts of compatibilizer

[0048] Phosphorus nitrogen flame retardant 20 parts

[0049] Phosphonate flame retardant 10 parts

[0050] 3 parts acid absorber

[0051] Flame retardant synergist 7 parts

[0052] Antioxidant 0.5 parts

[0053] Anti-hydrolysis agent 1.5 parts

[0054] The preparation method is as follows:

[0055] In the first step, after weighing the raw materials according to the weight ratio of the raw materials, first dry 40 parts of polyester elastomer and 15 parts of PBT in an oven at 120-130 ° C for pretreatment; in the second step, mix 3 parts of compatibilizer, phosphorus nitrogen 20 parts of flame retardant, 10 parts of phosphate ester flame retardant, 3 parts of acid absorbing agent, 7 parts of flame retardant synergist, 0.5 part of antioxidant, 1.5 parts of anti-hydrolysis agent are thrown into the high mixer and mixed evenly; the third step ...

Embodiment 2

[0057] Polyester type polyester elastomer 35 parts

[0058] Polybutylene terephthalate 20 parts

[0059] 5 parts of compatibilizer

[0060] Phosphorus nitrogen flame retardant 15 parts

[0061] Phosphonate flame retardant 15 parts

[0062] 3 parts acid absorber

[0063] Flame retardant synergist 5 parts

[0064] Antioxidant 0.5 parts

[0065] Anti-hydrolysis agent 1.5 parts

[0066] The preparation method is as follows:

[0067] In the first step, after weighing the raw materials according to the weight ratio of the raw materials, 35 parts of polyester elastomer and 20 parts of PBT are dried and pretreated in an oven at 120-130 ° C; in the second step, 5 parts of compatibilizer, phosphorus nitrogen 15 parts of flame retardant, 15 parts of phosphate ester flame retardant, 3 parts of acid absorbing agent, 5 parts of flame retardant synergist, 0.5 part of antioxidant, 1.5 parts of anti-hydrolysis agent are thrown into the high mixer and mixed evenly; the third step , add ...

Embodiment 3

[0069] 30 parts polyester elastomer

[0070] Polybutylene terephthalate 25 parts

[0071] 7 parts of compatibilizer

[0072] Phosphorus nitrogen flame retardant 10 parts

[0073] Phosphonate flame retardant 20 parts

[0074] 3 parts acid absorber

[0075] Flame retardant synergist 3 parts

[0076] Antioxidant 0.5 part

[0077] Anti-hydrolysis agent 1.5 parts

[0078] The preparation method is as follows:

[0079] In the first step, after weighing the raw materials according to the weight ratio of the raw materials, 30 parts of polyester elastomer and 25 parts of PBT are dried and pretreated in an oven at 120-130 °C; in the second step, 7 parts of compatibilizer, phosphorus nitrogen 10 parts of flame retardant, 20 parts of phosphate ester flame retardant, 3 parts of acid absorbing agent, 3 parts of flame retardant synergist, 0.5 part of antioxidant, 1.5 parts of anti-hydrolysis agent are thrown into the high mixer and mixed evenly; the third step , add the dried polyest...

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com