Preparation method for supported solid-acid catalyst for synthesising 2-isonaphthol via one-step hydroxylation of naphthalene

A solid acid catalyst, a naphthalene one-step hydroxyl technology, which is applied in the field of preparation of solid acid catalysts, can solve the problems of difficult separation and recovery of catalysts, difficult continuous production of processes, poor dispersion of active components, etc. low conversion rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Embodiment 1 Catalyst ZrSO4.nH 2 Preparation of O / HY (n=3)

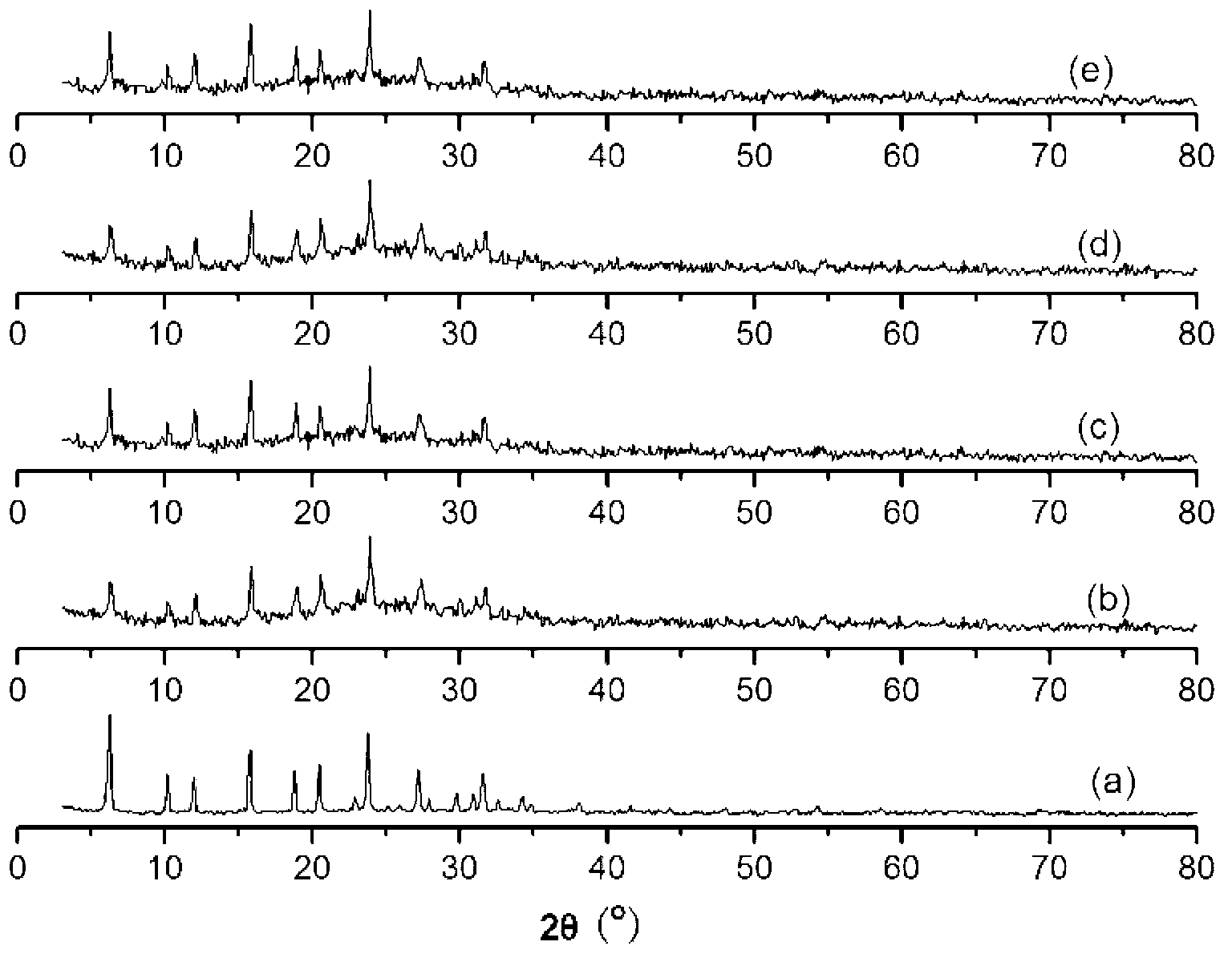

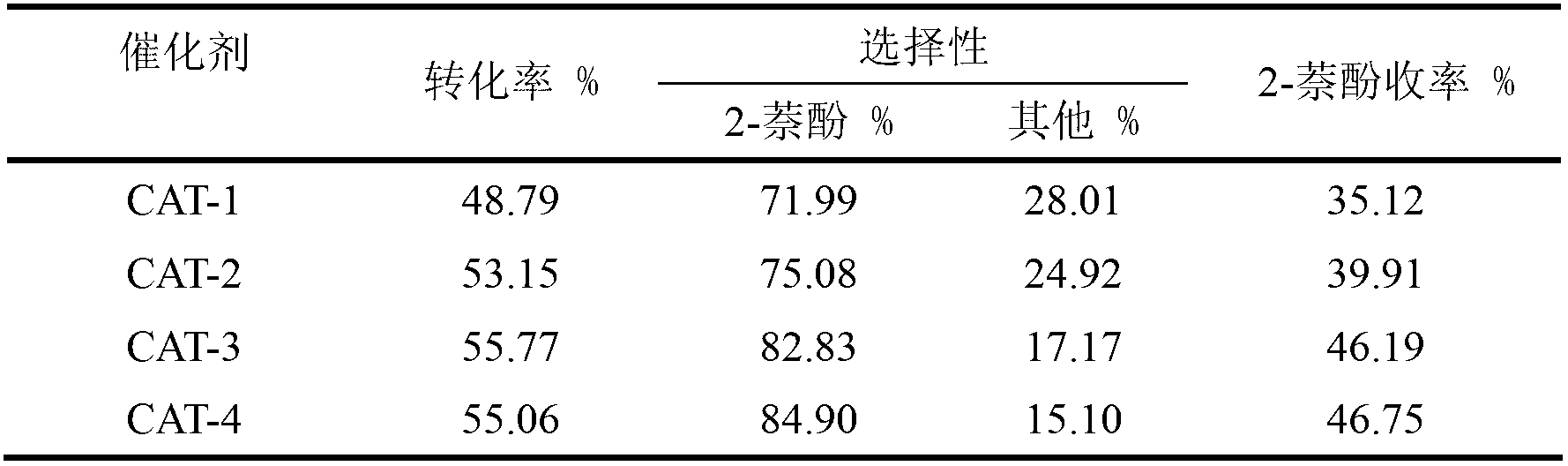

[0034] Accurately weigh 1g of the carrier HY and transfer it to a suction filter bottle, degas and dehydrate under a vacuum of 650mmHg; at the same time, accurately weigh 0.5g of zirconium sulfate, dissolve it in 6ML of deionized water, add a solution volume of 3% surfactant AEO- 9. Configure as impregnating liquid, transfer the impregnating liquid to the funnel integrated with the suction filter bottle, after the catalyst carrier is evacuated for 2 hours, turn on the switch of the funnel, quickly add the prepared impregnating liquid into the carrier, and impregnate the obtained The suspension was stirred for 2 hours, and then shaken by a low-temperature water bath oscillator at 40°C until the water was evaporated to dryness and the powder was cracked. The obtained powder was ground and baked at 110°C for 2 hours to obtain a supported solid acid catalyst ZrSO4.nH 2 O / HY, denoted as CAT-1, its XRD characteriza...

Embodiment 2

[0035] Embodiment 2 Catalyst ZrSO4.mH 2 Preparation of O / HY (m=1)

[0036] Accurately weigh 1g of the carrier HY and transfer it to a suction filter bottle, degas and dehydrate under a vacuum of 650mmHg; at the same time, accurately weigh 0.5g of zirconium sulfate, dissolve it in 6ML of deionized water, add a solution volume of 3% surfactant AEO- 9. Configure as impregnating liquid, transfer the impregnating liquid to the funnel integrated with the suction filter bottle, after the catalyst carrier is evacuated for 2 hours, turn on the switch of the funnel, quickly add the prepared impregnating liquid into the carrier, and impregnate the obtained The suspension was stirred for 2 hours, and then shaken by a low-temperature water bath oscillator at 40°C until the water was evaporated to dryness and the powder was cracked. Grind the obtained powder and dry it at 200°C for 2 hours to obtain a supported solid acid catalyst ZrSO4.mH 2 O / HY, denoted as CAT-2 (m≠n), its XRD characteri...

Embodiment 3

[0037] Embodiment 3 Catalyst CoO-ZrSO4.mH 2 Preparation of O / HY(m=1)

[0038] Accurately weigh 1g of the carrier HY and transfer it to a suction filter bottle, degas and dehydrate under a vacuum of 650mmHg; at the same time, accurately weigh 0.07g of cobalt nitrate and dissolve it in 6ML of deionized water, add 1% of the solution volume Surfactant AEO-9 , configured as an impregnating liquid, and transferred the impregnating liquid to a funnel integrated with the suction filter bottle. After the catalyst carrier was evacuated for 1 hour, the switch of the funnel was turned on, and the prepared impregnating liquid was quickly added to the carrier, and the impregnated The suspension was stirred for 2 hours, then shaken by a low-temperature water bath oscillator at 40°C until the water was evaporated to dryness and the powder was cracked, the obtained powder was ground, and then put in a muffle furnace for calcination at 400°C for 2 hours to prepare a Auxiliary solid acid cataly...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com