Composite molecular sieve-based catalyst for methanol to gasoline and preparation method and application thereof

A compound molecular sieve and methanol-to-gasoline technology, which is applied in the direction of molecular sieve catalysts, physical/chemical process catalysts, chemical instruments and methods, etc., can solve the problems of limited technology popularization and application, no breakthrough progress, frequent regeneration, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0056] (1) Preparation of catalyst

[0057] The preparation method of the ZSM-5 / MCM-48 composite molecular sieve-based catalyst provided by the invention to prepare gasoline from methanol comprises the following steps in turn:

[0058] ① Dissolve tetrapropylammonium hydroxide and aluminum isopropoxide in deionized water, stir until clarified, then add tetraethyl orthosilicate and sodium hydroxide aqueous solution dropwise, put it into a hydrothermal reaction kettle, under autogenous pressure and crystallization Crystallization under hydrothermal conditions at a temperature of 60-140°C for 2-6 hours to prepare the ZSM-5 microporous molecular sieve precursor;

[0059] ②Mix the ZSM-5 microporous molecular sieve precursor with cetyltrimethylammonium bromide sodium hydroxide aqueous solution (pH = 12), stir, and move it into a hydrothermal reaction kettle. Crystallize under hydrothermal conditions at -200°C for 4-12 hours, filter, wash, dry at 90-120°C for 6-24 hours, and roast at...

Embodiment 1

[0066] The molar ratio of each raw material prepared by ZSM-5 / MCM-48 composite molecular sieve is: TPAOH: TEOS: CTAB: NaOH: Al: H 2 O=0.137:1:0.12:0.55:0.0127:118.

[0067] Mix 11.328g of template agent tetrapropylammonium hydroxide (TPAOH) aqueous solution with a mass concentration of 25% and 59.212g of deionized water, add 0.26g of aluminum isopropoxide to the above solution, stir at a constant temperature of 35°C until clear, dropwise Add 21.24g tetraethyl orthosilicate (TEOS), add 0.2g sodium hydroxide to the above solution, continue to stir for 4h, transfer to the reaction kettle, and crystallize at 100°C for 4h. After the crystallization is completed, the reactor is taken out and cooled to room temperature to obtain a ZSM-5 precursor solution.

[0068] 4.459g of template agent cetyltrimethylammonium bromide (CTAB) was dissolved in 149.08g of sodium hydroxide in an aqueous solution with a mass concentration of 0.96%, stirred at 28°C until clear, and added dropwise to the...

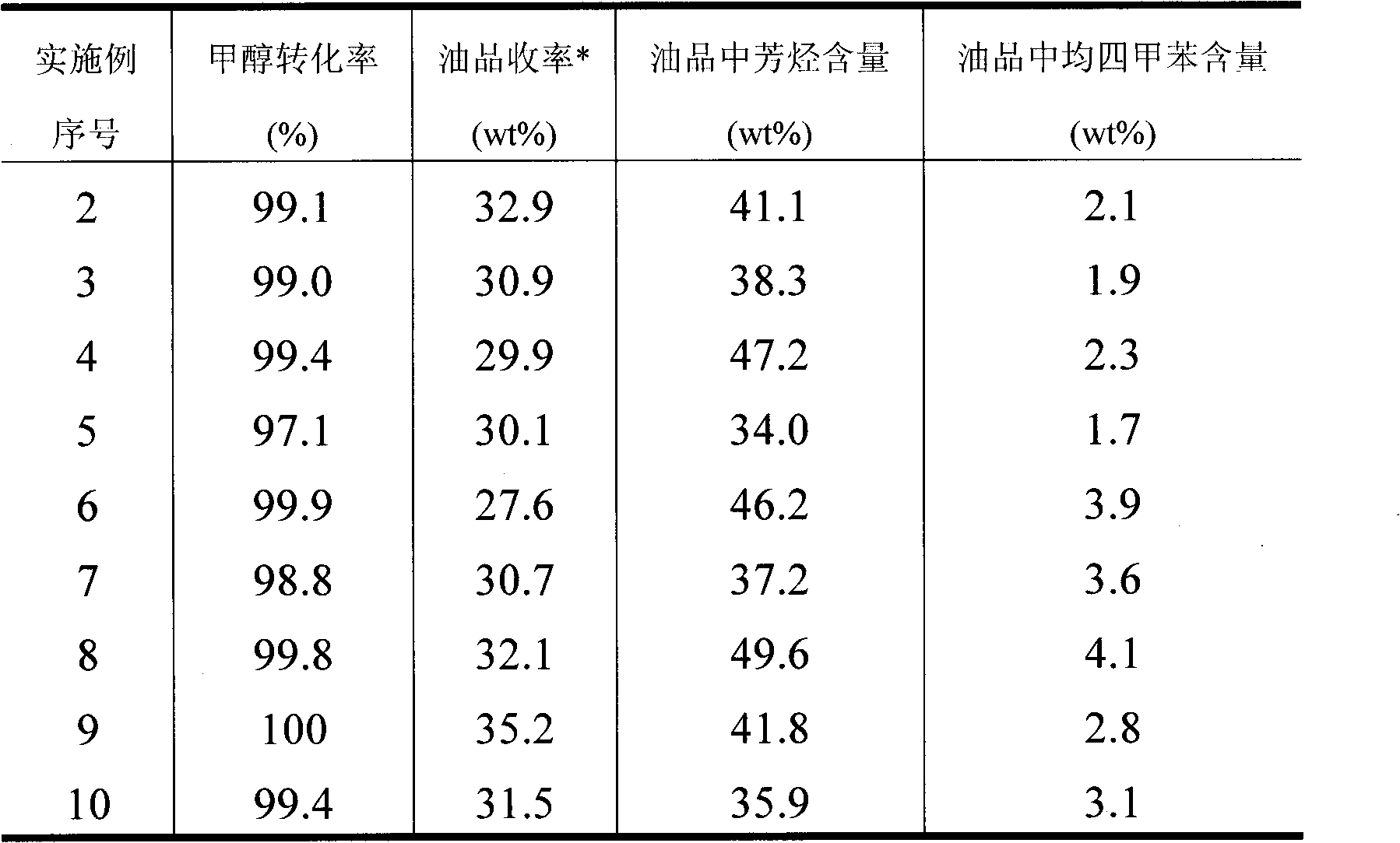

Embodiment 2

[0072] The molar ratio of each raw material prepared by ZSM-5 / MCM-48 composite molecular sieve is: n-butylamine: TEOS: CTAB: NaOH: Al: H 2 O=0.186:1:0.1:0.5:0.015:105.

[0073] 4.07g template agent n-butylamine (or ethylenediamine and ethylamine mixed in any molar ratio) aqueous solution with a mass concentration of 25% was mixed with 57.973g deionized water, 0.3064g aluminum isopropoxide was added to the above solution, 35 Stir at constant temperature at ℃ until clarification, add 21.24g tetraethyl orthosilicate (TEOS) dropwise, add 0.22g sodium hydroxide to the above solution, continue stirring for 2h, transfer to a reaction kettle for crystallization at 100°C for 6h. After the crystallization is completed, the reactor is taken out and cooled to room temperature to obtain a ZSM-5 precursor solution.

[0074] 3.72g of cetyltrimethylammonium bromide (CTAB) was dissolved in 133.54g of sodium hydroxide in an aqueous solution with a mass concentration of 1.34%, stirred at 32°C u...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com