Method for extracting persimmon leaf tartaric acid by combining microwave-assisted extraction and membrane separation

A membrane separation and microwave technology, which is used in pharmaceutical formulations, cosmetic preparations, preparations for skin care, etc., can solve the problems of large impurity content, unstable quality, long extraction time, etc., and achieve high yield and short extraction time. , the effect of significant economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

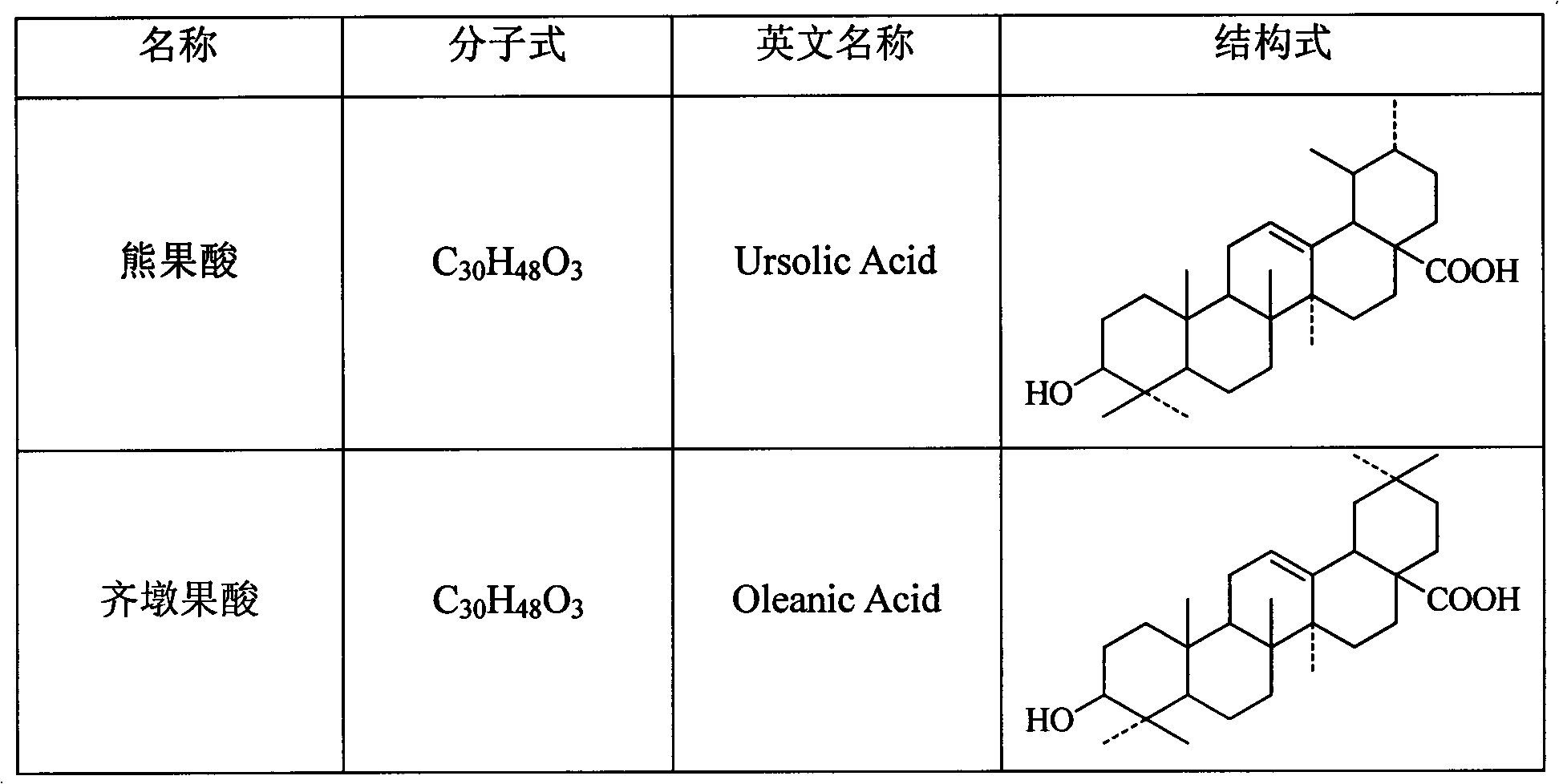

Image

Examples

Embodiment 1

[0030] Specific steps are as follows:

[0031] (1) After crushing the naturally dried persimmon leaves, add 8 times the weight of 55% ethanol to soak for 1 hour, extract in a microwave environment for 10 minutes, and keep the temperature of the persimmon leaves and the solution at 65°C;

[0032] (2) The above liquid is introduced into the operating system equipped with a filter membrane, and the filter operation is performed at a pressure of 0.3 MPa and a temperature of 60°C to remove impurities such as chlorophyll, polysaccharides, and tannins, and when concentrated to one-third of the original liquid For a while, add dialysis water to elute the organic acid;

[0033] (3) adopt low-temperature vacuum distillation to remove moisture, and concentrate the obtained organic acid aqueous solution until reaching one-fifth of the original volume, stop the distillation, and collect the concentrated solution;

[0034] (4) With 4% sodium hydroxide solution, adjust the pH value to 8, ca...

Embodiment 2

[0037] Specific steps are as follows:

[0038] (1) After crushing the naturally dried persimmon leaves, add 8 times the weight of 75% ethanol to soak for 1.5 hours, then extract in a microwave environment for 15 minutes, and keep the temperature of the persimmon leaves and the solution at 70°C;

[0039] (2) The above liquid is introduced into the operating system equipped with a filter membrane, and the filter operation is carried out at a pressure of 0.4 MPa and a temperature of 70°C to remove impurities such as chlorophyll, polysaccharides, tannins, etc., when concentrated to one-third of the original liquid For a while, add dialysis water to elute the organic acid;

[0040] (3) adopt low-temperature vacuum distillation to remove moisture, and concentrate the obtained organic acid aqueous solution until reaching one-fifth of the original volume, stop the distillation, and collect the concentrated solution;

[0041] (4) With 5% sodium hydroxide solution, adjust the pH value ...

Embodiment 3

[0044] Specific steps are as follows:

[0045] (1) After crushing the naturally dried persimmon leaves, add 8 times the weight of 100% ethanol to soak for 2 hours, then extract in a microwave environment for 20 minutes, and keep the temperature of the persimmon leaves and the solution at 75°C;

[0046] (2) Introduce the above-mentioned liquid into an operating system equipped with a filter membrane, and perform a filtration operation at a pressure of 0.5 MPa and a temperature of 80°C to remove impurities such as chlorophyll, polysaccharides, and tannins, and when concentrated to one-third of the original liquid For a while, add dialysis water to elute the organic acid;

[0047] (3) adopt low-temperature vacuum distillation to remove moisture, and concentrate the obtained organic acid aqueous solution until reaching one-fifth of the original volume, stop the distillation, and collect the concentrated solution;

[0048] (4) With 6% sodium hydroxide solution, adjust the pH value...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com